Please find quick guide Compressor Troubleshooting by Trevor Matthews below.

Watch the Trevor's webinar recording or read the article below

System Check Points

- Suction Pressure

- Suction Temperature

- Discharge Pressure

- Discharge Temperature (<225F/107C)

- Condenser Air In

- Condenser Air Out

- Liquid Pressure (Convert to Temp.)

- Liquid Temperature

- Condenser Out Subcooling

- Filter Temperature In

- Filter Temperature Out

- Moisture/Bubbles

- Liquid Pressure

- Liquid Temperature

- TXV In Subcooling

- Evaporator Air In

- Evaporator Air Out

- Evaporator Pressure (Converted to Temp.)

- Evaporator Out Temperature

- Evaporator Superheat

- Suction Pressure In

- Suction Pressure Out

- Compressor Superheat (~20F/11K)

Overheating

Compressors generate heat from the electrical motor, friction between different moving parts and heat of compression. When the compressor is running outside its operating envelope or its design conditions that is when problems begin.

What can cause overheat:

- High discharge temperatures

- High compression ratios

- High superheat

- Inadequate motor cooling

- High return gas

- Lack of external cooling

Overheating occurs anytime when oil in the compressor is heated so much that it will lose its ability to lubricate >300F/149C

How to prevent Overheating:

- Always check the discharge temperature 6" or 150mm from the dischargeservice valve and make sure you stay below 225F/107C Semi-Hermetics.Other compressors like Reciprocating Hermetic, Scrolls, Rotary, Screw willhave different values so you will need to check the manufacture manualforthose numbers. Example, some Scroll you want to keep them below260F/127C. If your above 225F/107C you need to investigatewhy.

- You want to make sure you maintain compression ratios per design. CopelandScroll Compressor for AC have a max of 11:1 before the floating seal unloadand refrigeration Scrolls are 26:1.

- Make sure you set minimum superheat so your return gas temperature backatthe compressor is not so high that the oil starts to lose its lubrication abilities(POE - 300F/149C) or breakdown (POE - 350F/177C)

- Always insulate the suction line because if it is not insulated it will pick up allthe heat in the space and bring it back to the compressor.

- Properly set low pressure control so that system does not take a very longtimeto pump down or run the compressor outside the compressor envelope.

- Make sure the Condenser is clean and there are no pressure drops inthesuction line

- Have the correct charge in the system so the refrigerant coming back cancoolthe compressor motor and stator.

- Use required cooling methods like head cooling fan, demand cooling orliquidinjection when required by compressor manufacture.

Flooded Starts

Flooded starts are caused by liquid refrigerant sitting in the crankcase with the oil because of refrigerant migration. Refrigerant migration occurs anytime refrigerant, and oil are in contact with each other, and the compressor is not running. The refrigerant will travel from the evaporator and move through the system as a vapour and condense in the compressor oil. The oil will float on top of the liquid refrigerant and when the compressor starts up the refrigerant explodes up out of the crankcase. Refrigerant is a good solvent and will wash oil off all the surfaces and cause metal on metal. For Scrolls you will see damage inside the scroll set but minimal damage to the drive bearing and bushing. For Semi Hermetics you could have the oil pump seized on or a seized rod on the crankshaft.

Things that affect refrigerant migration:

- Length of time the compressor is off

- The ambient temperature around the compressor

How to prevent Flooded Starts:

- Install and use crankcase heaters anytime that ambient around the compressor gets below 55F/12C because if the refrigerant wants to migrate to the coldest part of the system and if the compressor has a crankcase heater that will reduce the risk for flooded starts.

- Locate or relocate the compressor in ambient that will not cause migration

- Maintain an optimum refrigerant charge because there is something called refrigerant to oil charge ratio. You may have all the above checking fine and you still have flooded start issues, it could be the refrigerant to oil charge. Its a refrigerant to oil charge limit for manufactures. The more refrigerant and the less oil amount will result in more migration.

- Use a pump

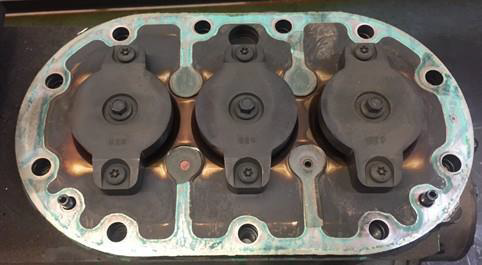

Liquid Slugging

Liquid slugging is the term used to describe the passage of liquid refrigerant into the scroll set or through the compressor suction and/or discharge valves. It is evidenced by a loud metallic clatter inside the compressor, often accompanied by extreme vibration of the compressor. If the compressor has a sight glass you will see an explosion of foam which is liquid refrigerant boiling off. Slugging in refrigerant cooled compressors is from a severe flooded start, which is a result from migration. Under extreme flooded start conditions, liquid (oil and or refrigerant) can be drawn into the suction passages leading to compressor cylinders or scroll set. When the compressor attempts to compress liquid, hydrostatic pressure is developed, resulting in failure of oldham coupling, scroll set and reed or discus valves.

How to prevent Liquid Slugging:

- Prevent Flooded Start conditions which is a result of refrigerant vapour migrating to the compressor crankcase oil or scroll during the offcycle.

- Operation and set points of the pump down control, and operation of the crankcase heater should be checked and verified for correct operation.

- Flooded Start Prevention:

- Install and use crankcase heaters anytime that ambient around the compressor gets below 55F/12C because if the refrigerant wants to migrate to the coldest part of the system and if the compressor has a crankcase heater that will reduce the risk for flooded starts.

- Locate or relocate the compressor in ambient that will not cause migration

- Maintain a optimum refrigerant charge because there is something called refrigerant to oil charge ratio. You may have all the above checking fine and you still have flooded start issues, it could be the refrigerant to oil charge. Its a refrigerant to oil charge limit for manufactures. The more refrigerant and the less oil amount will result in more migration.

- Use a pump down cycle so all the refrigerant is removed from the low side of the system.

Sign up on Refrigeration Mentor and get full a Free Compressor troubleshooting guide!

Liquid Floodback

System floodback is caused by low superheat. The liquid refrigerant makes its way back to the compressor while its running. If the refrigerant cannot boil off in the evaporator it will work its way back to the compressor and the oil in the compressor will become diluted and it will wash the oil off all the surfaces to the point where you have metal on metal at the load bearing surfaces like the drive bearing and bushing in a scroll and main bearing in a semi hermetic compressor.

What Causes Refrigerant Floodback:

- Damaged Metering device

- Oversized Metering

- Incorrect placement of TXV bulb or external equalizer

- Dirt or debris in metering device

- Wrong superheat setting

- Low Evaporator loads from poor air circulation

- Dirty filter, fan blades or coils

- Sudden changes in load like hot gas defrost or condenser fan cycling

How to prevent Liquid Floodback:

Sign up on Refrigeration Mentor and get full a Free Compressor troubleshooting guide!

Compressor Oil Loss

with insufficient lubrication caused by a lack of oil in the compressor. The reason(s) for the loss of oil in the compressor crankcase (oil logging) needs to be identified and corrected.Things that cause oil loss:

- Oil logging in the evaporator or other parts of the system and nothing returning back to the compressor

- Enough oil was not added when commissioned

- If the compressor short cycles too much oil will be pumped out and there will not be enough run time to allow oil to return

- Lack of lubrication leads to oil not lubricating compressor internals

- If the oil is being overheated, it could be too thinned out to lubricate.

- Suction line too large and may not maintain velocity of refrigerant for oil return

- If you have a restriction in the suction line or accumulator oil return plugged

- Loss of oil due to a leak.

How to prevent System Oil Loss:

Sign up on Refrigeration Mentor and get full a Free Compressor troubleshooting guide!