ECOSS – Presentation of a prototype for Europe

The Güntner Group presented a bestseller from the American market at Chillventa in Nuremberg: With the ECOSS Evaporative Condenser – it is entirely made from stainless steel and offers numerous advantages – Güntner rounds off its product portfolio leaving nothing to be desired.

The ECOSS Evaporative Condenser (Evaporative Condenser Stainless Steel) was originally designed in Brazil for air conditioning applications in the industrial sector and for EPC applications. In 2014, we presented a modified version for the US market. The numerous positive properties of the unit make it a bestseller, and as a result, a separate hall with several production lines was established at Güntner's plant in Mexico, exclusively for the manufacturing of these stainless steel units. In 2015, a specific version was developed for the Asian market; it is manufactured at the Surabaya production site in Indonesia. Also for this unit, the product launch was a great success.

Prototype adapted for EU market

The unit presented at Chillventa is a prototype specifically adapted to the realities of the European market. In addition to the pumps and fan solutions, also the dimensions were adapted accordingly so that there is a version exactly adjusted for container transport. This "Europeanised" version is exhibited at the trade fair to verify the interest of our customers and the market in such a solution.

Numerous application benefits

There is one thing all the regional versions have in common: The units provide several unique application benefits. The concept is a sophisticated solution for the industrial sector and for the field of energy and process cooling with their particular challenges such as water quality, passivation and oxidation. The stainless steel design of this innovative evaporative cooler provides the following advantages: It is extremely easy to install, it is self-passivating, it significantly increases the service life of the unit and it also offers unique system solutions for numerous operation and maintenance benefits. Some of the greatest benefits include huge savings in terms of water, energy and maintenance costs as well as a minimum use of chemicals, among other things. For maximum energy efficiency, the ECOSS unit is equipped with exceptionally energy-efficient fans that have a positive effect on operating costs and performance assurance, thanks to their unique, specifically developed Güntner Motor Management systems (GMM).

Güntner INDOOR series: Powerful and invisible

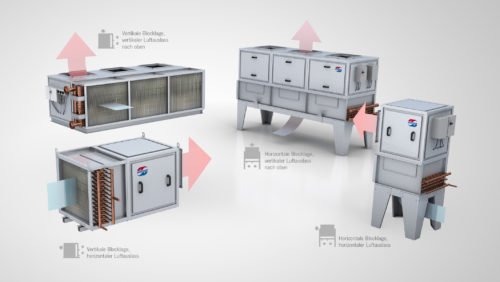

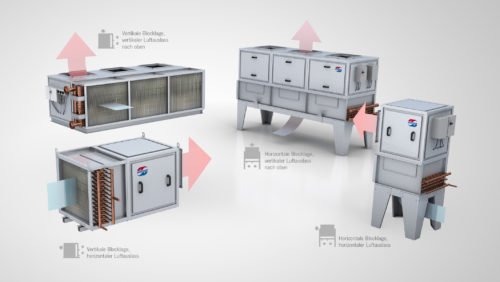

Güntner has always had a suitable solution for inner-city projects that are commonly characterised by scarcity of space for outdoor installation, strict noise protection and building regulations hindering a simple solution. The tried-and-tested units for indoor installation have been revised and are now available, in the form of the Application product line, for different airflow routings and with the option of individual adjustment.

The new INDOOR series equipped with AC or EC centrifugal fans have a capacity range of 10 to 700 kW and are available as condenser (GCHI/GCVI), fluid cooler (GFHI/GFVI) and gas cooler (GGHI/GGVI) for all common fluids. The centrifugal fans can be selected individually for air duct connection and there are also many variants available with regard to dimensions.

Robust and durable

The high-capacity heat exchanger coil is protected by a robust, durable casing which is always easy to transport – to make the bringing-in procedure even simpler, the units can be dismantled for delivery. The wide model range and the great selection of accessories make the units individually adjustable to the respective spatial situation and the desired airflow routing, and the sturdy construction with U-frame ensures a long service life.

Exact design

The extensive and modular concept with numerous material combinations and optimised pipe circuitings for every fluid ensures a customised unit designed with pinpoint accuracy for each and every application. The fin geometries and tube diameters, both adjusted to the respective operating fluid, also optimise the required tube volume. This results in a unit perfectly designed for the required application and capacity.

Unbelievable energy efficiency

High-quality EC fans paired with Güntner's energy-efficient control concepts produce unbelievably energy-efficient units with fans calculated and certified for the specific operating point. The specified capacity and energy data are reliable.

Reliable in operation and easy to maintain

The high degree of torsional stiffness protects the heat exchanger during crane and forklift transport. To make the bringing-in procedure simpler, the units can optionally be delivered in dismantled parts. Factory-mounted assembly groups such as control panels shorten the time needed for installation. The large standard inspection openings facilitate accessibility for maintenance and cleaning works. The specific fin geometry further facilitates effective cleaning.

Wide range of accessories

There are suitable accessories in different designs available for the units: For all types, there are connecting frames available for easy connection to air duct systems. The canvas sleeves for "structure-borne noise insulation" are used as elastic connection or flexible connectors. Louvres and suitable exhaust ducts are also available. And, of course, the suitable Güntner Motor Management System is available for every type.