Controlling air flow in an open display case is important for food retailers for several reasons. Proper air flow allows food products to be maintained at a desired temperature behind a curtain of cold air. If this cold air curtain or air flow pattern is disrupted, energy efficiency and product temperature performance can be severely impacted. Thus, by maintaining proper air flow, retailers can help ensure optimal product temperatures, product freshness, and energy efficiency in open display cases.

Understanding air flow

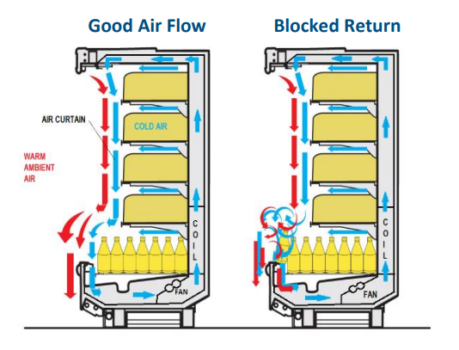

Open display cases operate with the use of axial fans that draw air in through the return air grill and push it through the evaporator coil. As the air is cooled, it moves further up the rear of the case, to the top, and out of the top discharge. The air discharge has a plastic honeycomb design that allows air to be evenly distributed from the top to the bottom return of the case. The air that is pushed down through the discharge creates a boundary curtain of cold air between the warm outside ambient air and the inside of the case that allows products to be maintained at a proper temperature. In addition to a properly flowing air curtain, to keep products at a uniform temperature, there must also be space between the shelves to allow air to flow from the rear of the case and around the products on each shelf.The effects of overloading on air flow

Standard loading criteria suggest that products are uniformly distributed throughout the case and kept behind the load limit to enable proper air flow. The load limit typically extends from the rear of the discharge honeycomb down to the rear of the return air grill as shown on the cross section in the case data sheets. As a result, the refrigerated discharge air can flow uninterrupted back to the return air grill, and products are maintained within an envelope of refrigerated air.

Most overloading occurs when product placed in the case extends past the load limit and into the air curtain. When this happens, the moving air of the air curtain is deflected by the product. In severe instances the refrigerated air can be deflected completely out of the case and warm store air is drawn back in by the fans to replace it. In more subtle occurrences the air curtain is only impeded enough to cause turbulence and smaller amounts of store air is entrained into the return air. In either case the disruption to the air curtain leads to less efficient operation and in the more severe instances it can also affect product temperatures. Too much product in a display case or pushing product against the rear wall of the display case can block the moiré (the slots in the interior back of the case) preventing cold air from entering the case from the back. Allowing airflow from the moiré in the rear of the case is important to maintaining product temperatures and supporting the air curtain at the front of the case. Overloading might also take the form of products being placed on the return air grill, which interrupts the circulation of cold air and creates more static pressure in the system so that the fan cannot deliver the required flow to cool or maintain the air curtain and product temperatures.

Avoiding improper shelf placement

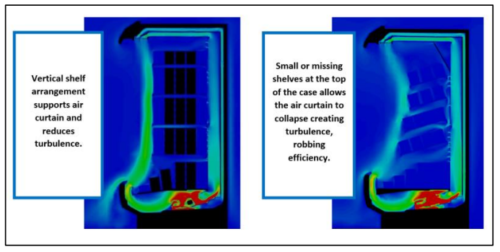

It is also important to use the proper shelves in each case to not only display the products but also support the air curtain. A vertical shelf arrangement is recommended in vertical profile cases to support the air curtain, reduce turbulence, and maintain efficiency. While using small or poorly positioned shelves at the top of the case allows the air curtain to collapse, creating turbulence and robbing efficiency.

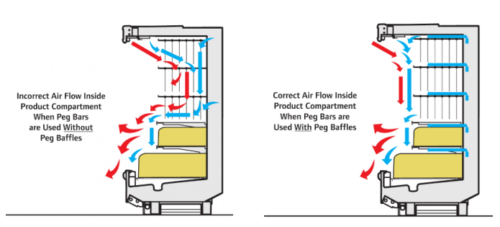

The impact of baffles on airflow

A baffle is anything that disturbs or redirects the flow of air. Air baffle shelves help direct air flow to support the air curtain and should always be used with peg bars for hanging deli meat and cheese displays. If there are no baffles on the peg bars, the discharge air will collapse into the case exposing the front products to room temperature air.

Testing to help ensure proper air flow

To help retailers maintain proper product temperatures, Hussmann conducts extensive testing of its case designs to determine conditions that affect energy efficiency and product temperature erformance. Air velocity and temperature distribution are controlled in the testing environment in order to understand the effects of airflow disruption.Air flow testing can be performed with computational fluid dynamics (CFD), which uses data and numerical analysis to simulate air flows. With CFD air velocity and temperature distribution are modeled to show how product overloading affects display case performance. To ensure testing accuracy, it is important that CFD testing is always followed with lab testing to validate results.

Based on these thorough testing procedures, Hussmann publishes merchandising load, installation and maintenance instructions to help retailers achieve product quality, higher efficiencies, and cost savings. This information can be found in all Hussmann data sheets and installation/operation (I/O) manuals.

Source: Hussmann