Changes to refrigerant regulations affect everyone, from manufacturers, to specifiers, designers to installers, facilities mangers to end users, and of course those certifying products such as Eurovent Certita Certification. So, when the EU’s F-Gas Regulations proposed a comprehensive HFC phase down, Eurovent Certita Certification knew that a wide number of refrigerants would be replaced to help to reach ambitious decarbonisation goals.

F-Gas Regulations and refrigeration

According to EU legislation to control F-gases, many Halogenated Fluorocarbon (HFC) refrigerants were phased out because of their high Global Warming Potential (GWP). The measures were built on the successful phase-out of ozone-depleting substances which was achieved in the EU 10 years ahead of the internationally agreed schedule. The aim of the F-gas Regulation is to cut the EU’s F-gas emissions by two-thirds by 2030 compared to 2014 levels.

Eurovent Certita Certification, as the third-party certification body, looks towards becoming the pioneer of ensuring the achievement of this legislation, through introducing new refrigerants into the scope of the programme for Heat Exchangers for refrigeration, and ceasing certifying the refrigerants phased out.

F-Gas calendar for banning HFCs

-

R 404A, R 507A and other fluids with a GWP ≥ 2 500 from 2020.

-

R 407C and R 410A and HFC with GWP ≥ 1500 from 2022 to 2025.

-

All HFC with GWP ≥ 150 from 2030.

Refrigerants and Eurovent’s heat exchanger programme (HE)

As a world leader in third-party product certification, Eurovent Certita Certification evolves its certifications in line with regulations, advances in technology and manufacturer requirements. As Eurovent uses European Standards as a baseline for its certification schemes, unsurprisingly, changes to refrigerant regulations affect a large proportion of certified products, including heat exchangers, condensing units and refrigerated display cabinets.

Eurovent has had to rewrite the certification rule book on applicable refrigerants. Under the HFC roadmap, the majority of refrigerants in the heat exchanger programme were due to be obsolete by 2030, leaving R-744 (CO2) as the remaining legal refrigerant post-2030.

The Programme Committee of Heat Exchangers for refrigeration, therefore, decided to extend the scope by including new refrigerants to increase the number of refrigerants in the programme. Knowing that low GWP Hydrofluoroolefins (HFOs) and refrigerant blends will rise in prominence alongside natural refrigerants, eight (8) new fluids were proposed because of their low GWPs, with R-454A, R-454B, R-1234ze and R-1234yf added to the programme scope for 2023.

For the remaining four proposed refrigerants, discussions are continuing around the inclusion of three refrigerants - R454C (GWP=148), R445A (GWP=90), and R455A (GWP=145) - with R515B (GWP=299) ruled out due to its high saturation temperature at ambient pressure.

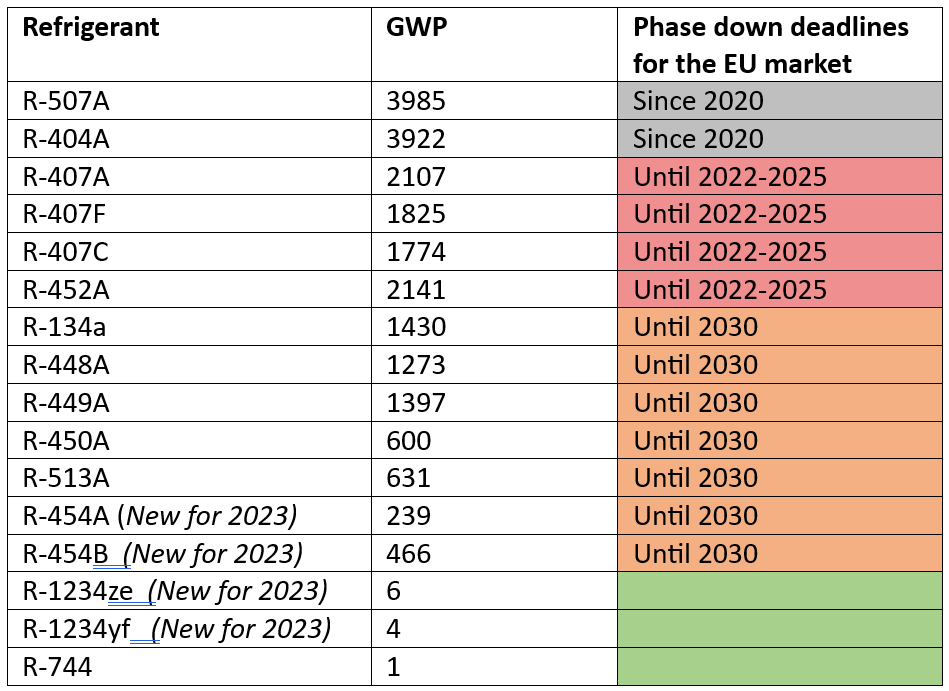

The current refrigerants scope of the Heat Exchanger programme, with the F-GAS phased down calendar, is presented in the following table:

Heat exchanger certification: Adapting to change

However, it’s not an easy process to add new refrigerants into the testing and evaluation process, and this is especially true of fluids such as ammonia, due to its toxic and flammable nature. Luckily this is not new ground for Eurovent Certita Certification and its partners in the heat exchanger programme. Due to the peculiar properties of R-744 (CO2), Eurovent had to establish a dedicated performance evaluation process for CO2 unit coolers and CO2 gas coolers, with a new state-of-the-art test rig developed at the Center of Competence for Refrigeration and Air-Conditioning of TÜV SÜD. Eurovent is well aware refrigerants will bring their own testing intricacies and challenges and is ready to adapt to find solutions.

In the heat exchanger programme, new rules have come into play around the now defunct R-507A and R-404A. For DX Air coolers and Air-cooled condensers, R-404A was used as a reference for calculation and R-507A as a testing refrigerant. Both refrigerants will no longer be declared or certified, but they will be kept in the certification rules to only be used as references until new reference refrigerants are identified.

Adaptions have also been made around product testing. Certification participants will now declare the performances of the three (3) identified common refrigerants, which are R-448A, R-449A and R-450A.

When it comes to the addition of natural refrigerants to the heat exchanger programme refrigerant list, it is clear the next steps should be the introduction of NH3. Brine is also a real possibility, though further discussion and consideration is required.

Refrigeration market supremacy

All the hard work will not be in vain. There are many reasons why natural refrigerants will gain dominance in the heat exchanger market, including:

-

Manufacturers will not have to make huge design changes to products to use refrigerants such as CO2

-

Legislation will push the market towards low GWP alternatives

-

·Natural refrigerants are readily available in the environment

-

Shortages in HFC refrigerants mean that natural refrigerants will be easier to procure and cheaper in price compared to HFCs.

Natural refrigerants are set to be the game changer for the HVAC and refrigeration industry. Eurovent research predicts that by 2025, Brine and ammonia will represent more than 20 percent of supermarket applications, more than 50 percent in industrial refrigeration, and 48 percent in air conditioning applications in Region EU28 + Switzerland + Norway. In addition, those new fluids along with CO2 will make up more than 70 percent of the European Heat exchanger market.

Conclusion

Eurovent Certita Certification, as the European leader in voluntary third-party certification, includes many fluids in the Heat Exchanges programme. To continue being a pioneer in transparency and reliability of certified performances by respecting the F-Gas regulation, Eurovent put efforts into covering the market needs as much as possible, by including new fluids with low GWP into the scope and removing the ones with high GPW.

Natural refrigerants will dominate the heat exchanger market going forward. And so, to remain as a leader in third-party certification, Eurovent Certita Certification must adapt programmes to market needs. The establishment of CO2 as a certified fluid, and the introduction of NH3 and Brine, alongside HFO refrigerants and refrigerant blends with low GWP, will cover the full market requirements.

The introduction of new certified refrigerants is a long and complicated process, and one which has to be done with scientific prowess for Eurovent to ensure programmes remain fit for purpose for the market. While the clock may be ticking, solid progress is underway, with programmes adapted to match the innovations of certified manufacturers.

If you would like to know more about the ECP Heat Exchangers programme please contact Japhet Habimana at j.habimana@eurovent-certification.com. Alternatively, you can search for certified heat exchangers via our online product directory at www.eurovent-certification.com