Most of the processes in the production, require strictly defined temperature characteristics, failure to comply with which can lead to problems and reduce the quality of the product. This applies to food, pharmaceutical, chemical, oil, metallurgical and other industries. Water or other liquid coolant cooling systems are used in air conditioning systems, vacuum packaging, in production with casting shapes, etc.

Efficient and economical water cooling is impossible without high-quality equipment, which can have a different design, depending on what technological tasks are put before him.

Among the most popular types of equipment for cooling water can be identified:

- chillers;

- the drycoolers take off;

- wet cooling towers;

- ice accumulators.

When choosing equipment, specialists are based on the needs of technological processes. Depends on the type and capacity of the equipment ie. This can be done only if you understand the design features of each of the presented types of devices for water cooling. Special refrigerating machines, which are used in the arrangement of Central air conditioning systems, called chillers. This equipment are designed to cool or warm up the liquid coolant (most often water or glycol) and forward it into the air conditioning system through a system of special pipelines to the place where the heat exchangers are installed. In addition, chillers are used in various technological processes, when the cooled coolant is supplied directly to the device, producing the technological operation. For example, when working with casting shapes, the constant temperature should be maintained. This is done by the chiller - it will give the coolant the desired temperature and forward it to the casting shapes.

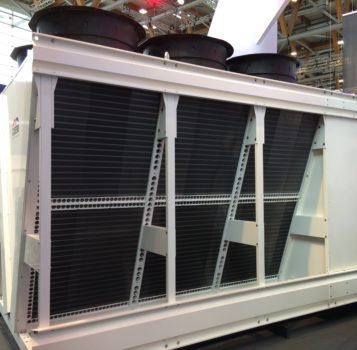

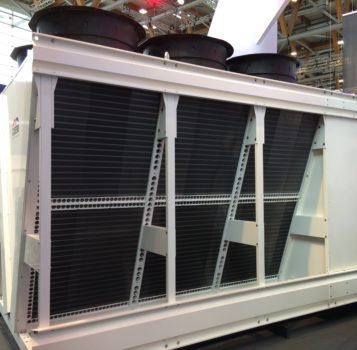

For cooling, a significant water flows that are used in various technological processes, to the ambient temperature are used dry coolers take off. It’s also called dry cooling tower. They work as additional equipment for cooling of chillers condensers and compressor-condenser units of other refrigeration equipment.

When cooling water on an industrial scale are widely popular usage of wet cooling towers, which are used in almost all sectors of modern production, where precise temperature control is required. Wet cooling towers are open and close types. In the first type of water when cooled leaves the air conditioning system and sprayed in front of the fan, effectively cooled by partial evaporation. In the closed version, heat exchange is carried out by means of a heat exchanger, which can be irrigated with water from special nozzles cooled by a fan, or by low temperature air, if, for example, the heat exchanger is placed outdoors in the cold season. But for this purpose as a heat carrier it is better to use glycol which does not freeze.

If water cooled to extremely low temperatures (about 0 ° C) is to be used as an intermediate coolant, ice accumulators are used. For this purpose, the water is placed in special thermally insulated containers, in which coils with a refrigerant circulating in them with a temperature below 0 ° C are located. A layer of ice freezing on them, the thickness of which is controlled by the equipment, cools the water passing through the tank to the desired temperature.

In the food industry, the technological requirements are often used significant amounts of water with a temperature of about 1 ° C. In this case, the water is distributed by a thin film on the evaporator with a refrigerant, thereby effectively cooled to the desired temperature. After that, already cooled to a temperature of 1 ° C, it flows into the drive and is fed through the pipeline to the right place for further use in production processes.