By Marcus Elmer, Director, Tube and Fittings, Copper Development Association

In today's increasingly environmentally conscious world, reducing the use of high global warming potential (GWP) refrigerants has become a crucial goal for industries worldwide. The HVAC/R industry, in particular, has recognized the urgent need to transition towards low(er) GWP alternatives from traditional hydrofluorocarbon (HFC) refrigerants.

HFC refrigerants, commonly used in air conditioning and refrigeration systems, are potent greenhouse gases known for their harmful impact on climate. These refrigerants have significantly high GWP, contributing to the depletion of the ozone layer and exacerbating global warming. According to the Environmental Protection Agency (EPA), HFCs can have a warming effect thousands of times greater than carbon dioxide. These staggering statistics highlight the urgent need to reduce HFCs and find more sustainable alternatives.

Regulatory bodies, such as the EPA, have taken decisive action to implement phasedown regulations for HFCs. These regulations create a framework that encourages HVAC/R equipment manufacturers to transition to low-GWP alternatives.

Transitioning to “modern” alternative refrigerants is emerging as a viable solution for reducing the environmental impact of HVAC/R equipment. The three main types of “modern” alternative refrigerants gaining prominence are Hydrofluoroolefins (HFOs), Hydrocarbons (HCs), and natural refrigerants. These alternatives offer lower GWP and zero ozone-depletion potential (ODP), making them an excellent choice for manufacturers looking to reduce their environmental footprint.

To meet today's industry needs, alternative refrigerants must have:

low toxicity, depending on the application. For example, Ammonia is natural but toxic.

zero, or as close to zero, ODP as possible;

lower flammability, depending on the application. For example, many naturals, like Propane, are flammable.

low GWP, once again depending on the application; and finally,

the thermophysical properties have to have a useful working range.

HFOs, such as R1234yf and R1234ze, have emerged as promising alternatives to traditional refrigerants with significantly lower GWPs than their predecessors. However, challenges, such as compatibility with existing equipment and increased cost, remain a consideration for HVAC/R equipment manufacturers.

There is increasing evidence that some HFOs like R1234yf are toxic, causing liver cancer and polluting water and land. The EU is working to ban these “forever chemicals” asap. Only R32 stayed on the list of acceptable refrigerants.

Natural Hydrocarbons, such as propane (R290) and isobutane (R600a), provide another viable option for transitioning to alternative refrigerants. These natural hydrocarbon-based refrigerants have low GWP and are widely used in small refrigeration systems. Safety concerns related to flammability can be addressed through proper handling and design considerations.

Other natural refrigerants, including carbon dioxide (R744) and ammonia (R717), offer a sustainable solution. R744 is non-flammable and non-toxic. In addition, it has a GWP of 1, compared to traditional refrigerants, such as R134a or R410a, which have GWPs of 1,430 and 2,088, respectively.

While they provide an extremely low GWP, carbon dioxide and ammonia have their own challenges for implementation, depending on the targeted end use. Carbon dioxide has high operating pressures, for example, and ammonia’s toxicity is not suitable for all applications.

As industries continue to adopt alternative refrigerants with lower GWP, HVAC/R equipment manufacturers are holding their breath, as they grapple with the various challenges in designing new heat exchangers for HVAC/R systems or redesigning existing ones.

But what factors drive these transitions, and what challenges do they present?

To answer these questions, we must discuss the design process and explore the considerations when transitioning to alternative refrigerants.

Three overarching factors drive heat exchanger design:

Environment and safety; i.e., direct refrigerant emissions, carbon footprint (e.g., CO2, end-of-life equipment), and safe material selection (resources).

Cost of material and tooling, including the impact of size/weight

Energy efficiency; i.e., the energy consumed in buildings, COP, billing cost, primary energy use, CO2 emissions, and partial load.

Physical properties and heat capacity: One of the most significant considerations when switching to a new refrigerant is the difference in physical properties, particularly heat capacity.

Higher-pressure refrigerants generally exhibit higher heat capacities. This results in wider vapor domes and larger enthalpy differences across the evaporation or condensation phase.

The upshot —

A refrigerant with a wider vapor dome and more heat capacity allows the manufacturer to achieve the same cooling or heating capacity while also reducing the refrigerant mass flow rate.

Conversely, transitioning to a refrigerant with lower heat capacity requires increasing the refrigerant mass flow rate to achieve the desired capacity.

Flammability and Toxicity: Another challenge when dealing with alternative refrigerants is finding suitable alternatives with low flammability and low toxicity. To address these challenges, the most common solution is to reduce the amount of refrigerant used, especially when it comes to using a flammable refrigerant alternative.

This can be achieved by designing heat exchangers with smaller diameter copper tubes, which reduces the internal volume of the heat exchanger (i.e. reduces the refrigerant charge amount). However, to prevent changes to system performance, proper heat exchanger design needs to take place.

When navigating these design challenges, there are several knobs manufacturers can turn to achieve optimal performance. Increasing the number of small tubes and tube circuits is often necessary when using smaller tubes or when a higher mass flow rate of refrigerant is required. However, these steps may introduce additional labor, material costs, and concerns about refrigerant distribution.

Increasing heat transfer performance can be achieved by adding more fins to the heat exchanger. This may not always be feasible due to limitations in fan capacity, available space, concerns around fouling, or because of condensate/frost issues. In such cases, longer or additional tubes can be an option, when system footprint or tooling changes are allowable.

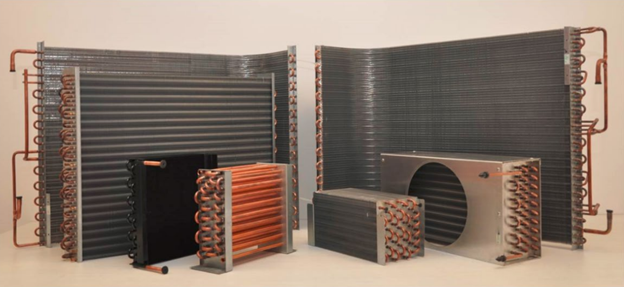

Photo Courtesy of LU-VE Spirotech

Small-Diameter Tubes: One effective tool for addressing design challenges in transitioning to alternative refrigerants is the use of small-diameter tubes and enhanced fins. Switching from larger diameter tubes to smaller ones allows for greater convective performance and improved heat transfer in a compact space.

This solution not only saves material but also minimizes the need for major changes to the product layout or enclosure design. However, it brings the challenges of circuiting and tooling to the forefront, as expertise and capital investment may be required to implement small-diameter tubes.

Copper's unique properties make it highly compatible with a wide range of refrigerants, including low GWP options.

Energy efficiency can be achieved at a lower material cost with smaller diameter tubes, and overall system size can be reduced.

In addition, smaller-diameter tubes can operate at higher pressures, making them more desirable as operating pressures increase. Working pressure is directly proportional to tube wall thickness and inversely proportional to tube diameter. In other words, for tubes with the same thickness, smaller diameter tubes can withstand higher pressures than larger diameter tubes.

Less material: Tube-diameter reduction results in more effective heat transfer and, consequently smaller, lighter coils. Less tube and fin material could provide equivalent heat transfer, or the same quantity of material could provide much more heat transfer.

Less refrigerant: A dramatic reduction in refrigerant volume is a further benefit of small diameter copper tubes. The smaller internal volume of the coils means that less refrigerant is necessary to charge the coil. The need for less refrigerant results in other design advantages, including a further reduction in overall system weight.

Durability: Coils made of copper tubes and aluminum fins or Round Tube Plate Fin (RTPF) are durable and dependable. They set the industry standard for corrosion resistance and long, reliable service life. Advanced coatings and surface treatments continue to improve durability in the harshest environments. The industry has found it difficult to improve upon the exceptional durability of copper tubes.

Familiarity: Tube suppliers, OEMs, mechanical systems engineers, and HVAC contractors all enjoy a high familiarity with CTAF technology. Up and down the value chain, the materials and processes are well understood. The fabrication, assembly, installation, service, repair, and recyclability are not substantially changed in the migration from conventional copper tubes to small-diameter copper tubes.

The paper titled Optimization of MicroGroove Copper Tube Coil Designs for Flammable Refrigerants details the use of propane (R290) and isobutane (R600a) refrigerants due to their ultralow Global Warming Potential (GWP) in refrigerator and freezer applications. To address their flammability, smaller copper tubes are commonly employed to reduce refrigerant charge. The process involves simulations, prototypes, and validation.

The authors utilized a proprietary heat exchanger design and simulation software tool to evaluate and optimize the performance of domestic refrigerator condenser coils made with 5-mm outer-diameter copper tubes. Through a comprehensive optimization study, new designs were identified to help achieve the primary objective of reducing refrigerant charge, along with the secondary objectives of minimizing both footprint and tube-and-fin material mass.

The optimized designs feature wavy-herringbone fins with reduced thickness[CM1] , resulting in significant reductions in tube volume and coil footprint, compared with the baseline design. The paper also details the presentation of test data validating the performance of prototype coils outlining the success of the design effort.

The first half of the webinar provides an overview of the background and motivation for using refrigerants with a lower global warming potential. The second half of the webinar provides case study examples of how the heat exchanger design should be reviewed and revised to use an alternative refrigerant successfully in a full vapor compression system

Marcus Elmer, Director of Tube and Fittings with the Copper Development Association, is a seasoned professional with over 15 years of experience in the plumbing and mechanical industries. He leverages his expertise to identify and influence market trends for copper tube and fittings products, driving strategic programs that encompass technical research, codes and standards, advocacy, and education. With a unique perspective gained from his time as a project manager with commercial plumbing, mechanical, and refrigeration contractors, Elmer has a deep understanding of the industry. He holds a Master of Business Administration from Union University in Tennessee and a Bachelor of Science in Construction from the University of Wisconsin - Stout.