Experience using R513a refrigerant in 3 ice arenas in the USA and Canada

"Energy consumption depends on usage, location, ice season and rental schedules. The I.B. Storey approach has documented savings (less consumption) of 13-22% over more traditional refrigerants such as ammonia and R22 in ice rink applications.", - Ian B. Storey P. Eng., the President of I.B. Storey.

We are pleased to present an exclusive interview with I.B. Storey team:

Ian B. Storey P. Eng.

Ian B. Storey P. Eng., is the President of I.B. Storey, the Official Rink Engineering Consultant of the NHL®. After over 20 years of providing innovative solutions, the independent speciality engineering firm is the recognized industry experts in recreational, commercial, and industrial sectors. The firm’s experience is unparalleled and has developed an industry leading reputation for designing and implementing innovative, cost effective, and sustainable refrigeration systems for a wide spectrum of clients ranging from community, semi-professional and NHL arena facilities across North America. The firm strives to deliver leading edge, cost effective and energy efficient systems to maximize a facility’s sustainability.

Ian Storey, P.Eng. is an award-winning industry expert honored with the Leadership Award by Efficiency Nova Scotia for his contribution and influential impact on the Energy Efficiency Industry. Previous accomplishments include being recognized by the Ontario Recreation Facilities Association as the recipient of the prestigious Don Harrison Energy Champion Award for his outstanding commitment to energy management.

Elvira Kadyrova

She was born in Chelyabinsk, Russia. Graduated from the St. Petersburg State University of Low-Temperature and Food Technologies with a degree in Service of Transport and Technological Machines and Equipment in Cold Supply Qualification Engineer. She followed in her father's footsteps into the refrigeration industry. After working in Russia for about 10 years, she received an invitation to live and work in the Canadian province of Prince Edward Island. She currently works for I.B.Storey, designing modern, safe and energy efficient ice arenas around the world.

Dear Ian, Elvira,

Please share with your experience of designing ice arenas.

Ri: Please tell us about your projects using R513a refrigerant. How many are those?

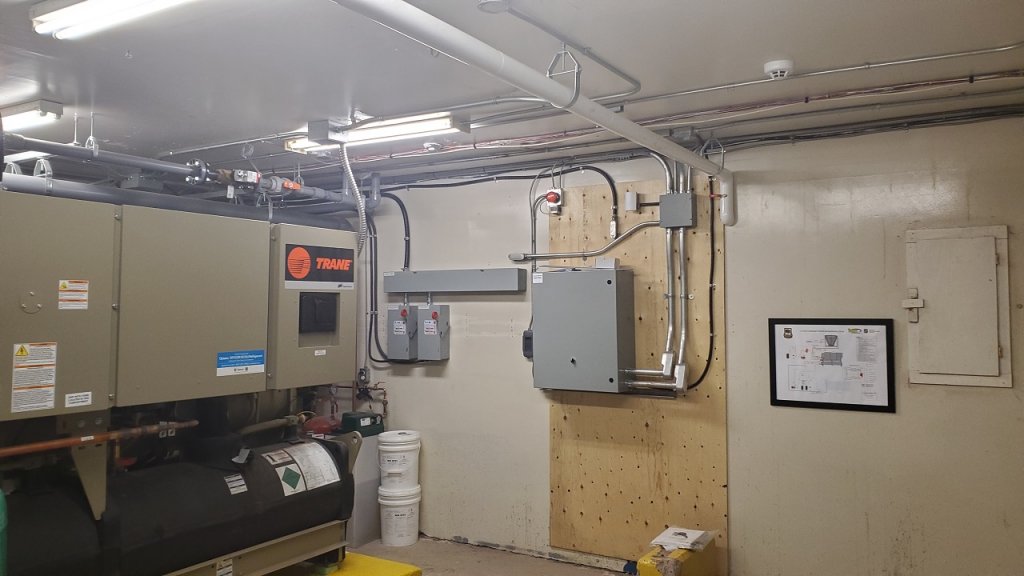

Elvira Kadyrova: At the moment, several projects have been implemented using the R513a refrigerant. One of the sites, Highland Park Arena, located in Illinois had equipment installed back in 1972 and a direct expansion system using R22 refrigerant. The project was implemented and put into operation in 2020.

48 years of use is a long time for any equipment, moreover during this time, not only maintenance standards and operating costs have changed, but also the requirements for the safety of refrigerants. Our team was challenged not only to change the equipment, but to design it in such a way that the system would be safe for employees and visitors of the arena, as well as energy efficient and easy to operate.

Another one of our recent projects, is the ice arena, located in the small town of O'Leary, with a population of about 815 people. The city is located in the Canadian province of Prince Edward Island, in the same province the head office of our company is based. This project was special for our team, we are proud to have such a unique opportunity to design an arena that meets safety and efficiency standards and is located here on PEI. The arena in O'Leary is now offering free skating lessons for everyone.

Case #1

-

Centennial Arena

-

Multi-purpose recreational facility

-

Owned and operated by the Park District of Highland Park, Illinois, USA

-

The facility had an aging refrigeration system facing the R22 phase out, I.B. Storey Inc. delivered Rink Engineering services in designing and oversight of the compressor replacement. The upgrades were designed in consideration of the client’s environmental targets, safety and lifecycle renewal.

-

Completed October 2020

Case #2

-

West Hants Sports Complex

-

Multi-purpose recreational facility with single sheet arena and attached turf complex

-

Owned and operated by the West Hants Regional Municipality, Nova Scotia, Canada

-

Energy Modelling and Specialized Rink Integration Engineering for the new multi-purpose facility. High efficiency equipment installed to achieve energy savings targets with I.B. Storey delivering specialized rink engineering for design and oversight of the construction progress.

-

Construction completed and new facility opened November 2020

Case #3

-

O’Leary Community Sports Center

-

Single ice sheet community arena

-

Owned and operated by Community of O’Leary, Prince Edward Island, Canada

-

Conceptual Design and independent project oversight for refrigeration room upgrades including new ice refrigeration plant, heat recovery integration, automation. Upgrades implemented for lifecycle renewal and operational savings for the arena which serves as a community hub.

- Completed November 2020

Ri: Why the R513a refrigeration system has been selected? Was the refrigerant selected before you started the project or did you change it while working on the project?

Ian Storey: R513a (Opteon Refrigerant XP10) has the ideal combination of properties for rink applications. The refrigerant was engineered to provide the optimal balance allowing I.B. Storey Inc to effectively balance safety, efficiency and environmental stewardship. This allowed for seamless adoption by experienced rink operators. R513a provides a non-toxic, non-flammable refrigerant solution with low GWP without compromise to efficiency across the range of operating conditions seen in ice rinks. Annually, this provides lower energy consumption with very safe and environmentally prudent operating conditions.

Elvira Kadyrova: Before deciding on what type of refrigerant will be utilized, our team completed a series of fundamental research. We plot P-H and T-S charts followed by modelling. Based on these results, our team is able to compare refrigerant properties for applications in multiple ice arenas. We know how the equipment will operate, how effective it will be in case of cooling capacity and energy consumption which are important as well.

Ri: What is the performance of refrigeration equipment at facilities?

Elvira Kadyrova: Our first facility using R513a refrigerant was designed and implemented in Ontario, Canada. The project increased the refrigeration capacity of the equipment by 49% while reducing electricity consumption by 13%. This is confirmed by electricity bills and analysis of equipment operation throughout the year. On our website https://www.ibstorey.ca, we post reports on our facilities, including a comparative analysis of the operation of equipment using various refrigerants.

Ri: What difficulties did you face in the design of the refrigeration system? How did you manage them?

Ian Storey: I.B. Storey had to address client concerns (internal to the project) and contractor reluctance (external to the project). As with embarking on anything new, the primary concerns were about ice quality and operating costs. I.B. Storey was able to assure clients that ice quality would remain as good or better compared to traditional approaches without incurring operating cost increases. As for the external project issues, most of these centered around attempts to use restrictive refrigerant selections that would limit the number of competing installers. These were addressed to full satisfaction of the clients concerned. From a purely technical standpoint, the very properties of R513a resulted in very modest technical challenges compared to implementing many other refrigerants as material compatibility and operating pressures were extremely flexible and favourable respectively.

Ri: What difficulties did you face during the implementation of the project e.g. equipment manufacturing, installation. How did you manage them?

Ian Storey: With anything new or different from previous installations, there remains a certain amount of issues during installation. Some of these are ongoing ownership concerns (while they trust I.B. Storey owners are also nervous to see their system operate) and contractors who are used to doing things the way it’s always been executed. Installers will often assume the engineer has made a mistake in these circumstances and often make decisions on how to proceed correctly which differ from the engineered plans. In order to manage these problems, I.B. Storey will use a variety of virtual and in-person inspection procedures as well as week conference calls with all parties to inspect progress and ensure correct installation. During start up, I.B. Storey also manages the entire process to minimize problems.

Elvira Kadyrova: Our team went to the installation site several times, during the entire installation and commissioning process. We checked the correct installation and connection of equipment, the process of cooling of the concrete slab, freezing of the ice in the rink, the operating parameters of the equipment and the operation of the entire system from unit to unit. At the last stage, commissioning was carried out from different parts of Canada. The employees from the office controlled and planned the process over the phone while the automation contractor started the equipment remotely, from the other end of Canada, and we, on the site, checked the whole process.

Ri: What first results did you get during the operation of the refrigeration system?

Ian Storey: With it’s low GWP and non-toxic properties, I.B. Storey has been able to provide the world-class rink systems without incurring operating costs increases and maintaining employee and patron safety. The low GWP of R513a illustrates industry leadership for these owners and further care was taken to ensure minimum opportunity for refrigerant leakage from the design systems.

As evidenced in our R513a case studies, I.B. Storey’s implemented designs can provide enhanced service and lowered operating costs compared to the previous industry-standard R22 and R717 systems.

Ri: Is the energy consumption within the planned range?

Ian Storey: Energy consumption depends on usage, location, ice season and rental schedules. The I.B. Storey approach has documented savings (less consumption) of 13-22% over more traditional refrigerants such as ammonia and R22 in ice rink applications.

Ri: What problems were identified during operation? How were they eliminated?

Ian Storey: Primary problems identified during operation include alignment of automatic alarming and safety switching. In essence these are nuisance system trips for the owner. To address these, additional automation design and implementation allows for the flexibility to streamline operation, save energy and eliminate nuisance alarming.

Ri: What is the feedback from the owner of the facility?

“I.B Storey’s leadership throughout our project was invaluable,” Chris Maliszewski, assistant director of recreation and facilities for Highland Park in Illinois said. “Their ability to seamlessly manage a project of this scope from afar due to challenges provided by the pandemic was nothing short of impressive. Our previous ice plant was installed in 1972 when the facility was built and used R22. When working with I.B. Storey we focused on ensuring our new system was cost efficient to install and operate, fit within the footprint of our facility, and utilized a refrigerant which met the districts vision of being environmental stewards. I am confident in saying that with Ian and his team’s leadership we met these goals and look forward to having an efficient and environmentally friendly system for skaters at Centennial Ice Arena for many years to come”

Ri: As we know, I.B. Storey designs similar projects in the USA. What are some differences between ice arenas in the USA and Canada?

Ian Storey: Projects in the USA typically need adjusting of equipment selections due to climate differences. As well, Canadian projects are often seasonal-ice facilities while USA facilities tend to be year-round more commonly. As such, the engineering approach differs to ensure effective and efficient ice operations under all conditions.

Ri: Thank you so much for your time and interesting interview!