With updated branding and an ever-expanding temperature-control product range that covers the full spectrum of cold to hot (including a new high-temperature solution), Frascold is strategically readying itself for a more sustainable future.

In an exclusive interview, Refrigeration Industry speaks to Frascold CEO Giuseppe Galli about the company’s vision, the rapid growth of its natural refrigerant business, and the expected impact of the updated F-gas Regulation.

How is Frascold positioning itself to continue its almost 90-year history of innovation and growth?

Refrigeration Industry (RI): At the end of last year, Frascold unveiled a new brand identity. What necessitated this change, and what does this say about the company's future direction?

Giuseppe Galli (GG): The change in Frascold’s brand identity was driven by the company’s dedication to sustainable innovation. This commitment is evident in our focus on energy efficiency, recycling initiatives, and the launch of new, eco-friendly solutions. The updated branding conveys the versatility of Frascold’s approach to temperature control, covering the full spectrum from cold to hot.

The introduction of a new grade symbol and fresh color palette in our communications serves to inform the stakeholders of our strategic shift towards a broader range of products, including those that can achieve higher temperatures. This rebranding signifies Frascold’s future direction towards a more comprehensive and environmentally conscious product line.

RI: Frascold also recently announced a new range of CO2 compressors. How important are natural refrigerant products for Frascold’s current and future portfolio (and why)?

GG: Frascold’s dedication to natural refrigerants like CO2 is a strategic part of our innovation and sustainability goals. We have been investing in research and development (R&D) of natural refrigerant solutions for the past two decades. We are pleased to see that the market is increasingly moving toward these natural solutions, thanks to a growing awareness of care for the environment and the passage of the new F-Gas

law, which will impose increasing limits on refrigerants with high Global Warming Potential (GWP) over the next few years.

Frascold is ready to meet this challenge through past and current R&D investments. In addition to their low carbon footprint, natural refrigerants allow us to develop high-performance products in total safety, combining our know-how and experience with their unique properties.

These eco-friendly solutions are key to our future product development, aligning with environmental regulations and market trends towards greener refrigeration technologies, such as our new CO2 compressors for heavy operations highlight our commitment to high performance and environmental responsibility.

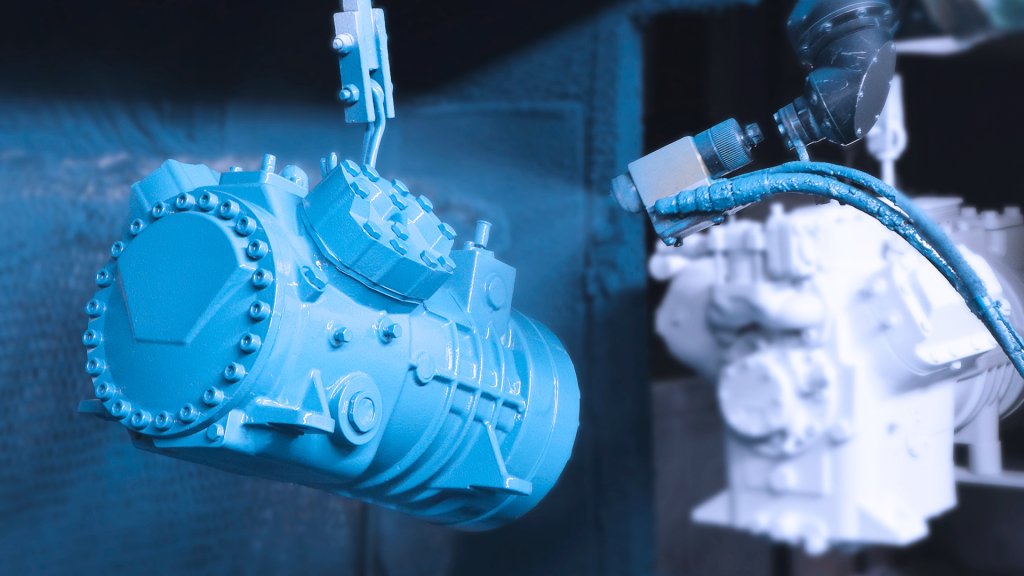

Frascold laboratory for CO2 compressors.

RI: This wasn’t the only new range Frascold has announced. You’ve consistently unveiled new and improved products. How important is R&D to Frascold, and why?

GG: At Frascold, we believe that continuous innovation is the key to embracing the future. We view this approach as a strategic tool for maintaining competitiveness in the global landscape. We are proud to invest substantially in R&D and to have an ongoing dialogue with major players in the HVAC&R industry and universities, such as the Politecnico di Milano, the Università di Padova, and several other universities around Europe and the world. This commitment allows us to transform each solution into real added value for customers, developing advanced technologies that ensure maximum continuity and reliability in each application context.

We view change as an opportunity to invest in incremental innovation. Our goal is to improve plants, processes, and know-how. This approach aims to optimize the efficiency of existing ranges in the short term and, in the long term, to create revolutionary solutions to address new challenges.

RI: What other products and services are you currently focused on regarding R&D?

GG: Now, we are focusing our efforts on R&D of products and services that are responsive to the evolving needs of the market. In particular, we are working on the development of new compressor sizes to meet any new needs and demands.

We are also exploring a new series of natural refrigerant compressors, to provide an innovative and sustainable response to the demands of various industries, ensuring broad coverage of current needs.

These efforts reflect our commitment to providing solutions that not only improve the efficiency and performance of our products but are also aligned with our environmental standards and sustainability expectations. R&D is a key pillar for Frascold, as it allows us to be proactive in the market and anticipate future trends, ensuring that our customers always receive the most advanced and reliable solutions.

RI: What percentage of your global business is made up of natural refrigerant products and services currently? How is this expected to grow in the near- to medium-term?

GG: Our global natural refrigerants business currently accounts for about 25% of our total business volume, with a double-digit annual growth each year. In recent years, Europe has been at the forefront of the evolution of natural refrigerants and is currently leading the global HVAC&R market in this important transition. In the United States, we are seeing an increasing number of applications using natural gases [refrigerants], with the goal of replicating the trend toward a more sustainable industry as experienced in Europe.

Сompressor painting process.

Сompressor painting process.

RI: Frascold has been around since 1936, what's the most popular manufactured product in the history of the company, and how has that changed over the years?

GG: In Frascold's nearly 90 years of operation, the size S of our piston compressor has been our most popular and market-demanding product. Over the years, we have met the demands of the market, first by developing higher-cube compressors with natural lubrication and then by designing ATEX-certified compressors to ensure total safety, which we have believed in from the beginning and are proud pioneers and market leaders.

We are also proud of are our screw compressors, which have been designed nearly 30 years ago and has reached the highest performance and efficiency.

RI: What has been the biggest learning opportunity for the company over its history?

GG: Our biggest learning opportunity has been the COVID-19 emergency. Despite the temporary closure of its plant due to the pandemic, Frascold was able to recover and achieve remarkable results. When we successfully reopened our production plant and offices after weeks of closure, we managed to report growth in production and sales. These achievements are a testament to the resilience and dedication of our hard-working team after the difficult period of the pandemic, and are a result of Frascold's continued investment in recent years and its expertise in natural refrigerants.

Furthermore, recently, with the introduction of the new F-gas law and the resulting shift in the market, we have had to adapt with a comprehensive redesign of most of our products to meet the challenge of natural refrigerants and low-GWP refrigerants, a process that was already ongoing but that required an acceleration in the R&D to ensure and deliver high-quality performance.

RI: What are the main challenges and opportunities Frascold faces in the current market, especially with the shift towards eco-friendly solutions?

GG: In the context of the current market challenges and opportunities, particularly with the shift towards eco-friendly solutions, we believe that Frascold’s most significant achievement is our innovative Testing Center. This facility, equipped with advanced test benches and a team of highly skilled technicians, is the foundation of our commitment to sustainability and high performance. It’s here that we develop and refine our compressors, which are the embodiment of our efforts.

We are pleased to offer efficient compressors that use natural refrigerants with a low environmental impact, thanks to the work done at our Testing Center. These compressors are a testament to our dedication to reducing emissions and consumption while safeguarding resources and improving efficiencies and performance. We believe that sustainable innovation is at the heart of Frascold’s business growth and our goal to lead the decarbonization process in the HVAC&R sector, playing a key role in the fight against climate change.

RI: How is the updated F-gas Regulation expected to impact Frascold’s business, and the global RACHP/ HVAC&R sector?

GG: Refrigeration is one of the biggest contributors to global warming, therefore, we take very seriously both the directions provided by the European community and the needs of industrialization of our customers. Certainly, with the passage of the new F-Gas law there will be a shift toward new refrigerants, both low GWP and natural refrigerants, in preparation for the restrictions that will occur in the coming years.

We, at Frascold, are hopeful that the market will reach a balance in the short term where there will be a compromise between sustainability goals and industry demands.

RI: Looking at the greater RACHP/ HVAC&R industry, what future trends do you predict for the next 5-10 years? How can companies prepare themselves better for the future?

GG: In the HVAC&R industry, short-term trends vary depending on geographical areas. In Europe, the focus is on sustainability and the decarbonization of HVAC&R. Over the next five to ten years, there will be significant development in technologies such as the replacement of boilers with heat pumps and the advancement of high-temperature heat pumps. These technologies extract thermal energy from the environment, promoting a rational use of energy and reducing waste of fossil fuel.

On the other hand, in other parts of the world, the priority is establishing the concept of the cold chain to preserve food and minimize resource waste. This is crucial for feeding future generations and achieving global food balance goals. The pursuit of sustainability and food balance go together, aiming to improve the quality of life across different regions of the world.

RI: What is your vision for Frascold? Where do you want to take this organization in the future?

GG: Frascold is a solid company pointing toward the future with a clear vision of internationalization, and the goal to make our products closer to our customers.

We are looking to become the trusted partner of new customers, specialized in new and innovative machines with natural refrigerants, while sharing our know-how. We believe that because of the transition towards natural gases, new producers of HVAC&R systems will need the help and guidance that we are ready to offer, as a consulting reference point for the customer.

Thanks you so much for the interview!