Revolutionizing Refrigeration: An Interview with Timur Sirman, CEO of MAGNOTHERM at Chillventa 2024

At Chillventa 2024, one of the world's leading trade fairs for refrigeration, air conditioning, ventilation, and heat pumps, Refindustry.com had the opportunity to sit down with Timur Sirman, CEO & Co-Founder of MAGNOTHERM. In an exclusive interview with editor-in-chief Sergei Mukminov, Timur shared insights into MAGNOTHERM's groundbreaking magnetic refrigeration technology and their latest products showcased at the event.

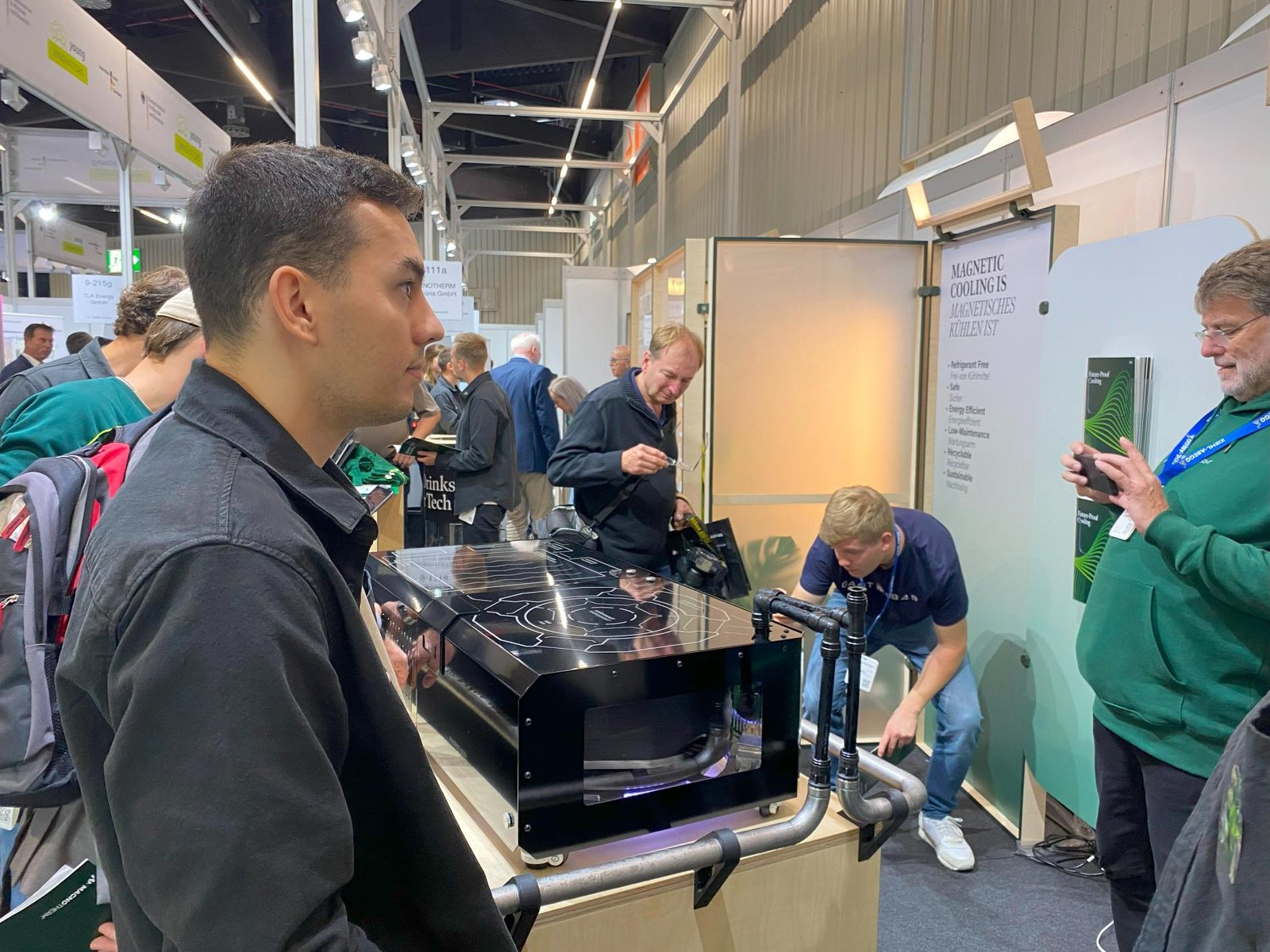

Sergei Mukminov (SM): Timur, thank you for joining us today. Could you tell us about the product you're showcasing here at Chillventa?

Timur Sirman (TS): Absolutely. Here at our booth, we're showcasing the Polaris beverage cooler, which is essentially our minimum viable product for magnetic refrigeration. It's already certified and operational in local supermarkets around the Frankfurt area in Germany. This demonstrates that our technology is reliable and works effectively in real-world settings.

SM: That's impressive. What is the cooling capacity of the Polaris unit?

TS: The Polaris has a cooling capacity of 40 watts, but we can scale it up to 200 watts within the same form factor. Additionally, for the first time, we're unveiling the upscale version of our technology—the Eclipse unit. You can take a look inside to see how it operates.

SM: That's exciting. Could you explain how your technology works without traditional refrigerants?

TS: Certainly. Both the Polaris and Eclipse units operate without conventional refrigerants. We utilize a process called Active Magnetic Regeneration (AMR). By magnetizing a specialized metal alloy, it heats up, and when we demagnetize it, the metal cools down. We then transfer this heat or cold to a fluid—in this case, water—using a pump that circulates it from a water reservoir.

SM: What innovations have you made in this field?

TS: Our innovations are twofold: on the machine side and the material side. We're now able to produce low-cost, high-quality magnetic materials based on lanthanum-iron-silicon alloys (La(Fe,Si)₁₃). This material is protected by our specialized copper coating, enhancing its performance and longevity.

SM: How did MAGNOTHERM originate this idea?

TS: The technology originated at the Technical University of Darmstadt, where Professor Oliver Gutfleisch has been researching magnetic materials for quite some time. The lanthanum-iron-silicon material system and the specialized copper coating were developed there. Initial research activities began as early as 2002. MAGNOTHERM was incorporated in 2019, but we started our developments in 2018. In 2021, we spun out from the university and now have our own facility with 800 square meters of office and workshop space, where we build our units manually.

SM: How many units have you produced so far?

TS: We've built 40 units to date. With the Eclipse unit being publicly shown for the first time here, we're now entering new markets to produce this equipment and sell our technology.

SM: What are your plans for market entry and expansion?

TS: We aim to push the technology forward as a provider of magnetic cooling solutions. We sell our cooling units for integration into various applications and also supply the magnetic materials to other companies. To expedite market entry, we've developed our own refrigerator. In four weeks, we'll be releasing a two-door cabinet designed for supermarkets and beverage manufacturers. It can be used as a beverage cooler or for convenience items, and this paves the way for us to expand into dairy and meat cooling in the future.

SM: Do you have any partnerships to support this expansion?

TS: Yes, we have collaborations with several supermarket chains. With our product launch in November, we'll begin taking pre-orders.

SM: That's fantastic news. Thank you, Timur. We look forward to seeing how MAGNOTHERM will impact the refrigeration industry.

TS: Thank you, Sergei. It's been a pleasure speaking with you.