Case Study - Effect of Louvers or diffusers on air flow distribution and cooling time on a meat log during Chill cycle

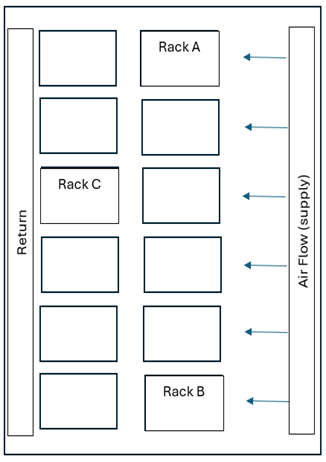

An experimental analysis was conducted on a cooler space measuring 3.66 m × 6.096 m (12.0 ft × 20.0 ft), equipped with an ammonia refrigeration coil, five 30 cm (12 in.) fans, and five diffusers. The study measured airflow patterns, cooling rates, and heat transfer efficiency in meat storage by testing two configurations: one with diffusers and one without. The meat was stored in two rows on a total of twelve racks. Performance data were collected and analysed to evaluate the impact of airflow distribution on cooling efficiency.

Fig 1 shows racks loaded with product in a cooler with diffusers

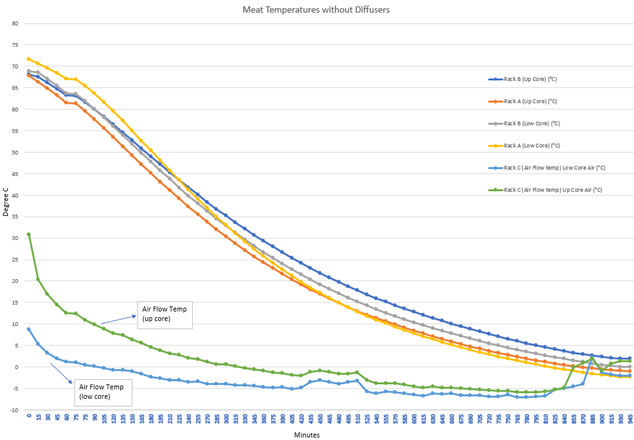

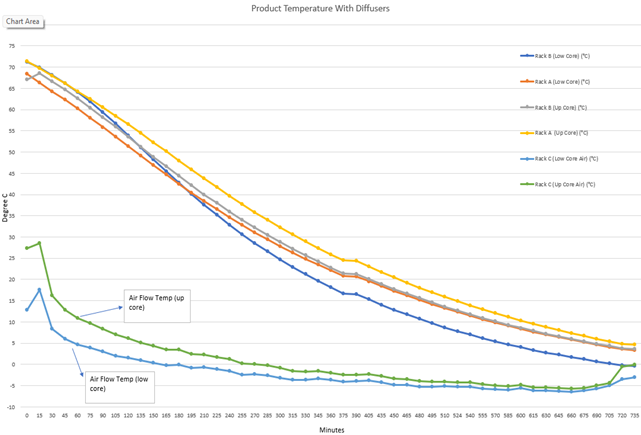

The product core temperature profiles from the two trials:

- Trial 1 – without diffusers (“Meat Temperatures without Diffusers”)

- Trial 2 – with diffusers (“Product Temperature with Diffusers”)

The focus is the chilling cycle down to 4 °C (39.2 °F), taken as the target safe storage temperature.

Fig 2 shows the diffusers installed in the cooler

Fig 3 shows the Cooler layout

In both trials, the four product cores (Rack A/B, upper and lower) start around 68–72 °C (154.4–161.6 °F). This indicates that the initial thermal load is comparable, so differences in cooling behaviour can be attributed mainly to the presence or absence of diffusers and the resulting airflow pattern.

Without diffusers, cooling is relatively slow, with a noticeable spread between racks and between upper and lower cores. Through most of the cycle the upper cores remain 2–4 °C (3.6–7.2 °F) warmer than the corresponding lower cores, showing poorer vertical temperature uniformity. Between roughly 300–600 min (5–10 h), product temperatures decrease from ~30 °C (~86 °F) down to about 7–12 °C (44.6–53.6 °F). Around 800–900 min (13 h 20 min–15 h), at least some cores remain above 4 °C (39.2 °F), and the hot–cold spread is still evident.

With diffusers, the cooling curves are steeper over the same time range, indicating an increased heat transfer rate. The four core lines are more closely grouped, typically within ~1–2 °C (~1.8–3.6 °F) of each other at any given time, showing improved uniformity between racks and between upper and lower cores. From 300–600 min (5–10 h), product temperature falls from ~30 °C (~86 °F) down to ~5–10 °C (41–50 °F), several degrees colder than the no-diffuser case at the same elapsed times. Air temperatures are consistently lower and more stable, sustaining a higher driving temperature difference between air and product.

Because the charts are read from plotted points (not raw data), the times below are approximate but sufficient to quantify the effect. Without diffusers, the coldest cores (lower racks) approach 4 °C (39.2 °F) around 810–840 min (13.5–14.0 h). The warmest cores (upper racks) reach the same level later, around 840–900 min (14.0–15.0 h). Overall, it takes on the order of 13.5–15 h from loading for all monitored cores to cool to approximately 4 °C (39.2 °F).

With diffusers, the coldest core appears to cross 4 °C (39.2 °F) around 660–690 min (11.0–11.5 h). The remaining upper cores reach ~4 °C (39.2 °F) by roughly 705–735 min (11 h 45 min–12 h 15 min). Thus, all cores reach the 4 °C (39.2 °F) target in about 11.0–12.25 h.

Without diffusers, there is a persistent temperature offset between upper and lower cores (upper cores warmer), which could challenge compliance if acceptance is based on the warmest point. With diffusers, this offset is reduced to roughly 1–2 °C (1.8–3.6 °F), indicating a more even airflow distribution and lower risk that a “hot spot” remains above 4 °C (39.2 °F) when average product appears compliant. In the no-diffuser case, there is more variability and a small re-warming in air temperatures near the end of the cycle, coinciding with a flattening of the product curves; with diffusers, air temperatures are smoother and more negative, supporting a continuous approach to 4 °C (39.2 °F) without visible interruption.

Fig 4 Meat Core & Air Flow Temperature Drop Over Time Without Diffusers

Fig 5 Meat Core & Air Flow Temperature Drop Over Time With Diffusers

Thus, introduction of airflow diffusers:

-

Shortens cooling time to 4 °C (39.2 °F) by approximately 2–3 h (120–180 min) for both fastest and slowest product cores.

-

Improves temperature uniformity between racks and between upper and lower cores, reducing late-cycle hot–cold spread from ~3–4 °C (~5.4–7.2 °F) to ~1–2 °C (~1.8–3.6 °F).

-

Maintains lower and more stable air temperatures, increasing the effective driving temperature difference and sustaining a higher cooling rate.

Author

Cargill Inc

Engineering Manager

Read other articles by the author: