Total Cost of Ownership (TCO) for Modular Refrigeration Systems in Life Sciences Distribution Centers

by Ramez Naguib, P.E.

Introduction

Life sciences distribution centers are under immense pressure to deliver consistent temperature control, comply with increasingly stringent regulations, and optimize operational efficiency. Traditional built-up refrigeration systems often prove cumbersome, costly, and slow to implement. In contrast, modular, factory-assembled refrigeration systems have emerged as a compelling alternative. Drawing on lessons from mission-critical sectors such as data centers, where modular plants have already proven transformative, this article outlines how modular refrigeration provides measurable advantages in total cost of ownership (TCO).

It is important to recognize, however, that no single solution works for every project. Modular approaches provide powerful benefits in the right contexts, but project-specific factors—such as legacy infrastructure, site constraints, and budget priorities—will ultimately guide the best system choice.

Enhanced Reliability and Redundancy as a Foundation

Life sciences facilities such as blood banks and biorepositories store extremely sensitive products that demand consistent and precise temperature control. Modular systems distribute cooling capacity across multiple units, offering built-in redundancy (N+1 design). If one module malfunctions, others compensate, minimizing risk of system failure and ensuring continuous preservation of vital materials. This reduces downtime and supports uninterrupted critical operations.

Mission-critical environments—whether preserving life-saving blood supplies or powering high-availability data centers—cannot afford downtime. Modular systems inherently offer distributed reliability through N+1 redundancy: if one module fails, others immediately compensate, ensuring continuity of service. This principle, first championed in containerized cooling plants, now underpins modern refrigeration strategies for life sciences facilities.

Precise Temperature Control and Monitoring

Modular systems allow targeted temperature control across zones, minimizing hot spots and ensuring uniform storage conditions. Advanced monitoring features—including digital thermostats, deviation alarms, and remote monitoring—provide real-time assurance of compliance with stringent regulatory requirements. This precision directly reduces the risk of spoilage and costly product loss.

Key Cost-Saving Advantages

1. Streamlined and Reduced Time for Permitting

Pre-engineered modular units and factory-built systems are designed to meet codes and standards from the outset, simplifying permitting. Pre-certified designs accelerate approval timelines, minimize rework, and reduce costs associated with delays in review cycles.

2. Improved Quality

Quality control measures during off-site fabrication ensure consistent system performance. With defects identified and corrected before shipment, on-site errors are minimized. This results in fewer warranty claims, lower maintenance costs, and enhanced long-term reliability.

3. Speed of Execution On-Site

Modular construction significantly reduces on-site labor and installation time. Projects reach completion faster, enabling earlier operations and revenue generation. For distribution centers, this shortened timeline lowers overall risk while increasing speed to market. Off-site assembly dramatically reduces on-site labor. Facilities can begin operations weeks, even months, sooner—a direct parallel to data center deployments where modularity consistently accelerated project phasing.

This is one of the key advantages for projects where time saving is paramount, whether due to regulatory deadlines, market expansion, or urgent supply chain requirements.

4. Ease of Maintenance

Modules can be serviced independently, without system-wide shutdowns. This reduces downtime and labor costs while ensuring continuous operation. Predictive maintenance is facilitated by advanced monitoring tools, further reducing unplanned service interruptions.

Flexibility, Scalability, and Energy Efficiency

Modular refrigeration systems can expand with operational needs. Additional modules can be integrated quickly, avoiding costly overhauls. The modular nature also supports relocation if facility requirements change. Individual modules operate independently, optimizing cooling where it’s needed and reducing energy consumption. Modern modular units often include energy-efficient components that further lower operating costs.

This adaptability also makes modular systems ideal for rolling out expansions or supporting phased growth strategies, where capacity must be added in increments rather than all at once.

Options for Modular Designs

Several modular configurations are available to meet varied needs:

- Packaged Systems

Fully integrated, skid-mounted units including refrigeration, controls, and power distribution. Ideal for plug-and-play deployment with minimal site work. - Skid-Mounted Systems

Core refrigeration components pre-assembled on skids. These offer scalability and adaptability, striking a balance between factory assembly and site flexibility. - Modular Room-Based Systems

Pre-fabricated coolers or freezers that can be shipped and assembled rapidly on-site. Suitable for facilities needing quick expansion or reconfiguration. - Hybrid Designs

Custom combinations of packaged and skid-mounted units designed for unique site constraints or operational goals.

These pre-packaged or skidded systems are especially beneficial when projects face local labor constraints—such as shortages of skilled trades, excessively restrictive labor contracts, or high costs in both domestic and international markets. By moving work to a factory-controlled environment, they reduce reliance on scarce or expensive site labor.

Benchmark TCO Impacts (vs. Traditional Built‑Up Systems)

The following benchmarks synthesize published industry research and case studies to quantify potential savings. Actual results depend on scope, scale, local labor markets, and design maturity.

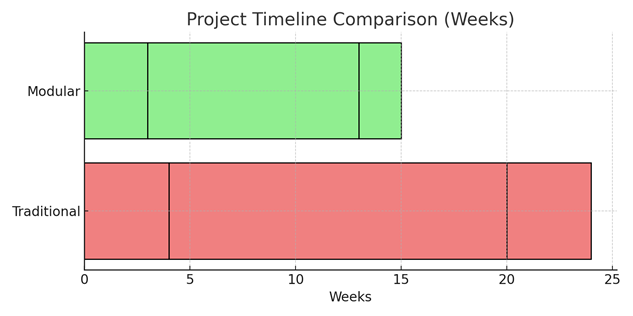

Schedule (Time to Start‑Up) - 20–50% faster overall construction schedules with modular/offsite methods. - 6–12+ weeks reduction in MEP/utility critical path is common when major plants are skid‑built. - Permitting: standardized, pre-engineered packages often shorten AHJ review cycles and reduce resubmittals.

Figure: Project Timeline Comparison (Traditional vs Modular)

Direct Construction Cost - 5–20% reduction in installed cost driven by less rework, fewer RFIs/change orders, and compressed site overhead. - On‑site labor hours shifted offsite (factory) lower composite labor burden and reduce trade stacking/inefficiency.

Quality & Commissioning - Factory QA/QC lowers punch‑list volume; pre‑functional tests reduce commissioning duration and callbacks. - Fewer field welds/joins and standardized controls reduce startup defects and temperature stability issues.

Operations & Maintenance (O&M) - 15–30% lower first‑five‑years service spend via improved access, standardized parts, and module‑level isolation. - 20–40% reduction in mean time to repair (MTTR) due to plug‑replaceable subassemblies and better diagnostics.

Safety & Risk - Fewer on‑site man‑hours and reduced labor density lower incident exposure and insurance/contingency carry.

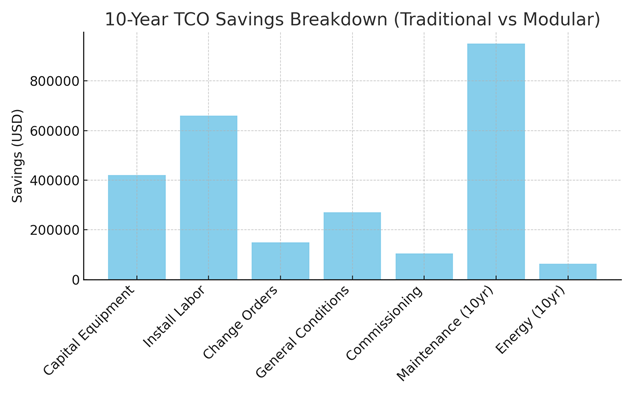

Illustrative 10‑Year TCO Comparison (example)

Figure: 10-Year TCO Savings Breakdown by Category

Assumptions for a single life‑sciences DC refrigeration scope; replace with project‑specific numbers during estimating.

|

Category |

Traditional Built‑Up |

Modular/Factory‑Assembled |

Delta |

|---|---|---|---|

|

Capital equipment & materials |

$6,000,000 |

$5,580,000 |

–7% |

|

On‑site install labor & OH |

$2,200,000 |

$1,540,000 |

–30% |

|

Change orders/RFIs rework |

$300,000 |

$150,000 |

–50% |

|

General conditions (time‑based) |

$900,000 |

$630,000 |

–30% |

|

Commissioning & punchlist |

$350,000 |

$245,000 |

–30% |

|

Subtotal Capex |

$9,750,000 |

$8,145,000 |

–16.5% |

|

Annual preventive maintenance |

$220,000 |

$170,000 |

–23% |

|

Annual corrective maintenance |

$160,000 |

$115,000 |

–28% |

|

Energy (controls optimization) |

$1,050,000 |

$987,000 |

–6% |

|

10‑Year Opex (PV) |

$3,200,000 |

$2,750,000 |

–14% |

|

10‑Year TCO |

$12,950,000 |

$10,895,000 |

–16% |

Result: In this example, modular delivery lowers 10‑year TCO by ~16% (~$2.05M) while also bringing revenue forward due to earlier start‑up.

Sensitivity Notes - If local labor scarcity/prevailing wages are high, modular savings on install labor and general conditions trend toward the upper range. - Highly repetitive programs (multi‑site networks) gain additional savings via standardization and learning‑curve effects. - Energy savings vary with controls strategy (e.g., VFDs, floating head/low‑condensing temp, high‑efficiency compressors), envelope, and utility rates.

The chart below illustrates the cost comparison between traditional built-up and modular/factory-assembled refrigeration systems across major cost categories over a 10-year horizon.

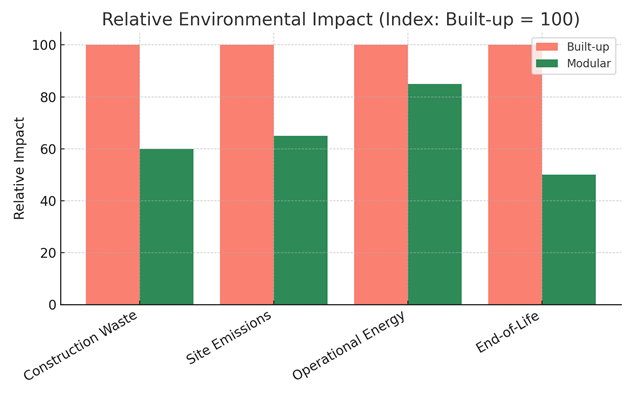

Figure: Environmental Impact Comparison of Built-up vs Modular Systems

|

|

10-Year TCO Comparison

Environmental Impact Analysis

Reduced Construction Waste

Traditional built-up refrigeration systems often generate significant waste due to on-site fabrication, excess materials, and field modifications. In contrast, modular packaged systems are manufactured in controlled factory environments, where material use is optimized and scrap is minimized. This results in less construction waste reaching landfills and lower embodied carbon in the construction phase.

Lower Carbon Footprint from Site Activities

Built-up systems require extended on-site labor, heavy equipment use, and multiple trade mobilizations, all of which increase fuel consumption and greenhouse gas emissions. Modular packaged systems shorten on-site activities considerably, reducing diesel usage from cranes, generators, and transportation of labor forces.

Energy Efficiency in Operations

Factory-assembled modular units often incorporate the latest energy-efficient compressors, controls, and heat exchangers. This results in lower energy consumption over the system’s lifetime compared to many custom-built installations. Reduced energy demand directly translates into fewer CO₂ emissions from electricity generation.

Lifecycle Sustainability

Because modular units can be relocated, upgraded, or repurposed, their useful life is extended, reducing the need for new equipment manufacturing. By contrast, built-up systems are typically decommissioned and scrapped when a facility changes, generating additional waste and embodied carbon.

Comparative Impact

-

Built-Up Systems: Higher construction waste, longer site emissions period, potentially less optimized long-term energy use.

-

Modular Packaged Systems: Lower embodied carbon in construction, shorter on-site emissions period, and greater operational energy efficiency.

This environmental dimension adds to the TCO advantage, as sustainability goals and carbon reduction commitments are increasingly central to corporate strategy.

Applicability and Best Use Cases

Modular refrigeration systems provide strong advantages but are not a universal fit. They are best suited for new construction projects, where planning for modular integration from the outset maximizes savings and efficiency. They are also:

-

Ideal when time saving is critical—such as projects facing urgent operational deadlines.

-

Well-suited for expansions or phased growth, where capacity must be added incrementally.

-

Effective in labor-constrained environments, where shortages of skilled trades, restrictive labor contracts, or high domestic/international labor costs pose risks.

By strategically applying modular approaches to these contexts, organizations can unlock maximum value.

Conclusion

When evaluating total cost of ownership, modular refrigeration systems present clear advantages for life sciences distribution centers. Benefits extend beyond capital cost savings to include:

-

Faster permitting and approvals

-

Consistent, higher quality builds

-

Quicker on-site execution and start-up

-

Easier maintenance with minimized downtime

-

Scalable, energy-efficient performance

By choosing the right modular configuration—packaged, skid-mounted, room-based, or hybrid—organizations can optimize operational reliability, reduce risk, and achieve superior long-term financial performance while meeting the strict demands of the life sciences industry.

End Notes

1. McKinsey & Company (2019). Modular construction: From projects to products. McKinsey Global Institute.

2. Dodge Data & Analytics (2020). Prefabrication and Modular Construction 2020 SmartMarket Report.

3. U.S. Department of Energy (2024). Industrialized Construction: The Case for Modular.

4. Dodge Data & Analytics (2020). Prefabrication and Modular Construction SmartMarket Report (Survey Results).

5. Vargas, M.Q., et al. (2025). Integrating Off-Site Modular Construction and BIM for Sustainability Outcomes. Sustainability, 17(17), 7791.

6. Naguib, R. (2011). The Economics of Modular Infrastructure. Mission Critical Magazine

Author

Ramez Naguib, P.E.,

President of Clima-Tech LLC in Los Angeles, California.