Carrier Transicold has significantly increased its installation capability, skills and capacity in the UK to meet the growing demand for engineless refrigeration systems. The business is proud to offer an electric solution for 100% of its vehicle ranges and is committed to growing adoption of the units.

Investments by Carrier Transicold and two longstanding network service partners, Lynton Refrigeration and Robson Refrigeration, trading as Carrier Transicold Northern and Carrier Transicold East & North Yorkshire respectively, ensure the brand is well positioned to meet growing demand from fleets, bodybuilders and vehicle manufacturers for engineless units – which are key to helping fleets improve the sustainability of their operations.

“We’re pleased to announce the opening of two installation centres of excellence in the UK, each geographically close to major bodybuilders," said Mark Daniels, Service Director at Carrier Transicold UK. “In addition to training and hiring additional installation engineers, our partners have invested in larger facilities which offer the ultra-clean and safe working environments required when installing hydraulics and handling high-voltage electrics.”

In Manchester, Lynton Refrigeration invested nearly £2 million to acquire a new dedicated installation site, and has grown its team of installation engineers from seven to 15, with additional recruitment planned for this year.

“Our vision is to create a one-stop shop for the complete installation of Carrier Transicold units,” said Scott Walsh, Director of Lynton Refrigeration. “On top of the investments made to-date, it’s quickly become apparent we need even more workshop space, so we have added four more bays with a modular workshop system, and we’re now drawing up plans for further extensions to our main installation building and storage areas, to ensure we can meet demand as it scales further.”

In Hull, Robson Refrigeration has hired an additional 12 team members and invested in new equipment for its recently opened workshop, plus added a new modular work area for greater installation capacity. The company is also planning to grow its team by an additional five team members this year to keep up with demand.

“The requirement for engineless units will only increase as more fleets experience the environmental advantages of these Carrier Transicold systems, so the business case for our investment made total sense,” said Colin Robson, Managing Director of Robson Refrigeration. “We’re proud to be playing our part in increasing installation capacity across the network.”

Carrier Transicold has also hired five installation technicians, who can be deployed to work with manufacturers and bodybuilders on proof-of-concept projects and special builds.

“They have quickly proved to be a real strength to our business,” added Daniels. “The electrification of the industry is seeing rising demand for bespoke builds, meaning we can be installing our equipment onto a new chassis design or working with new driveline technologies for the first time. These can be highly complex installations and manufacturers are coming to our team as the trusted experts.”

Collectively, Carrier Transicold and its network partners now have more than 70 engineers dedicated to installation activities across the UK, installing the full range of temperature-controlled equipment onto light commercial vehicles, rigid trucks and trailers.

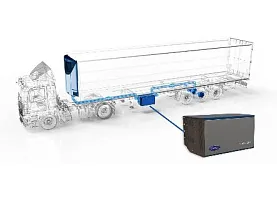

Carrier Transicold’s engineless temperature-controlled refrigeration systems take power directly from the truck's engine or electrified powertrain. For diesel trucks, units such as the Iceland and Syberia are electrically driven by the Eco-Drive power module, which is in turn hydraulically powered by the clean, efficient, Euro-6 truck engine. On zero-direct emission electric trucks, Carrier Transicold uses its power box converter to connect the refrigeration unit to the OEM main battery pack.