Danfoss Climate Solutions has started manufacturing its GBC 45 and 49 bar shutoff ball valves at its facility in Monterrey, Mexico, as part of a strategy to regionalize HVAC component production for the North American market. The move aims to reduce delivery times and improve supply chain resilience in Danfoss’ largest market.

Previously, all GBC shutoff valves were produced in China. By localizing production, Danfoss aims to increase flexibility and better support its customers in the Americas. The company noted that demand is rising for these valves as customers transition to alternative refrigerants.

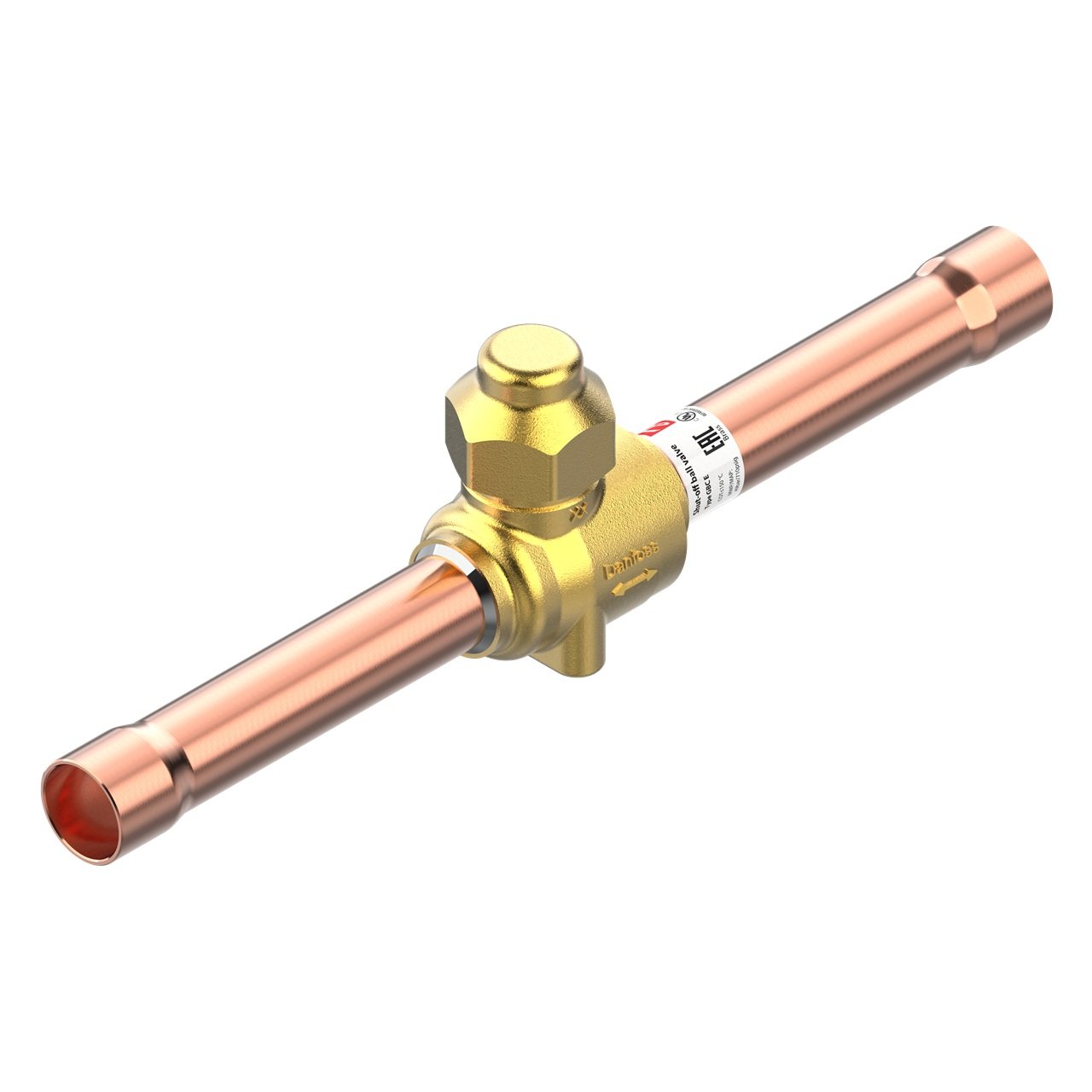

The GBC 45 and 49 valves are manually operated, bi-directional shut-off devices compatible with A1, A2L, and A3 refrigerants. They are used in liquid, suction, and hot gas lines for refrigeration, air conditioning, and freezing applications. The valves are constructed from rupture-resistant, custom brass and manufactured using advanced processes, including auto-brazing, laser welding, and helium leak testing.

Danfoss replicated its manufacturing processes from China to the Monterrey plant, involving collaboration across global teams to ensure consistency and product quality.

"This dual production strategy for GBC 45 and 49 valves represents our commitment to both our customers and the future,” said Sony Martinez, director of sales for Danfoss Climate Solutions in Mexico. “By bringing production closer to our customers in the Americas, we are strengthening our supply chain and ensuring they have access to the high-quality products they need, when they need them.”

Douglas Custodio, director of sales development for Danfoss Climate Solutions in North America, added: “Expanding production to North America will enable us to meet growing demand and further assist our customers in their decarbonization and energy efficiency goals.”