09 February 2026

Danish partners develop 3D-printed cooling solution for data centers

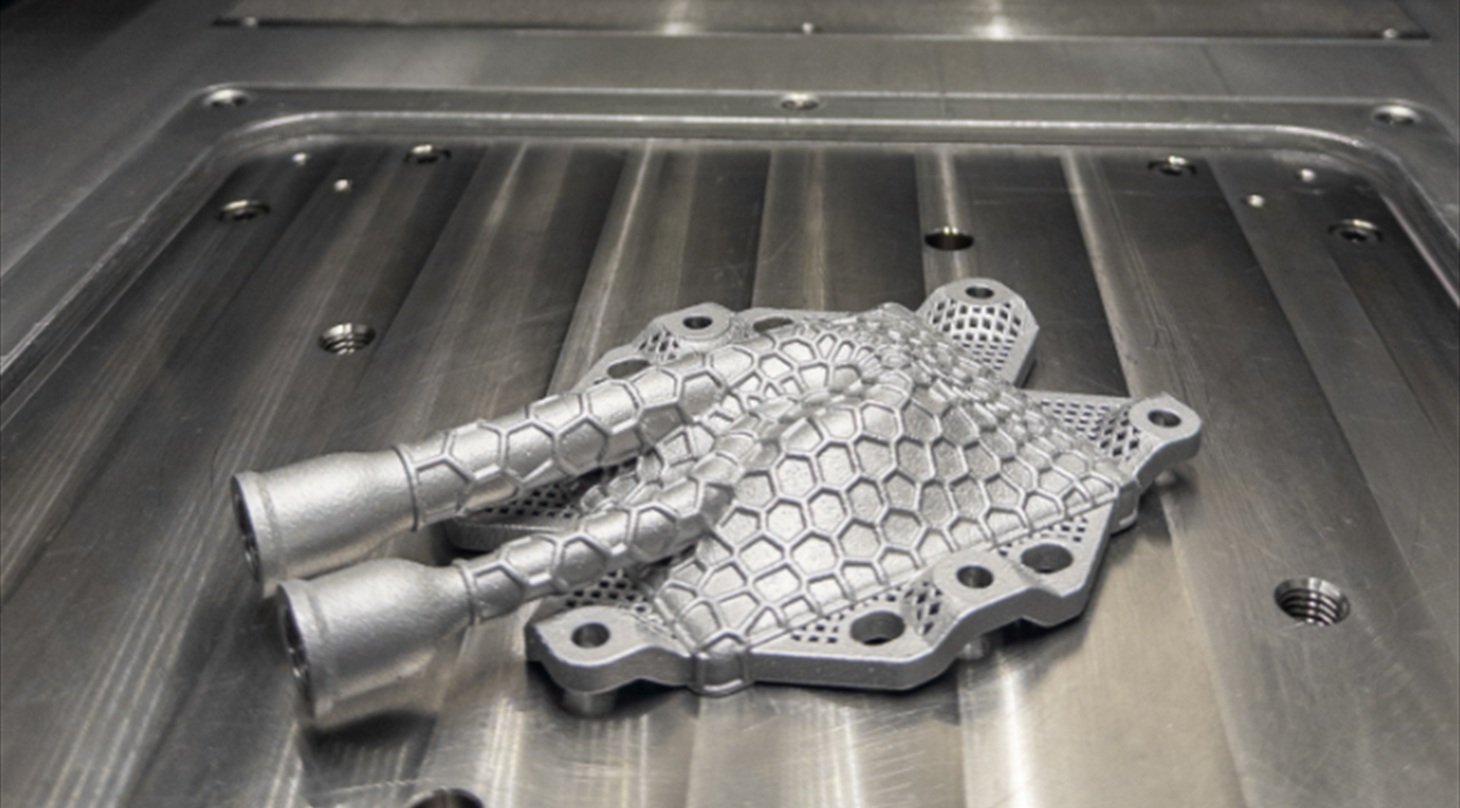

Danish Technological Institute and Heatflow have developed a new energy-efficient cooling component for data centers, using 3D printing and passive two-phase cooling. The solution, demonstrated in the European AM2PC project, significantly reduces energy consumption and enables reuse of excess heat for district heating.

The 3D-printed aluminium component acts as an evaporator, using a thermosiphon principle to remove heat without pumps or fans. In tests, the system achieved a cooling capacity of 600 watts—50% higher than the original target of 400 watts. This approach addresses the growing energy demand in data centers, especially as GPU power density increases.

“The power density in servers is increasing faster than ever before, and traditional air cooling is no longer sufficient,” said Paw Mortensen, CEO of Heatflow and AM2PC project lead. “With our two-phase solution, we can remove heat passively without pumps or fans, which significantly reduces the energy consumption for cooling.”

According to Simon Brudler, 3D-printing specialist and senior consultant at Danish Technological Institute, 3D printing in aluminium allows all functions to be integrated into a single part. This eliminates assembly points, reduces leak risk, and improves recyclability.

A key outcome of the project is the system’s ability to remove heat at temperatures between 60–80°C, making the waste heat suitable for district heating or industrial use without additional energy input. Traditional air cooling typically extracts heat at lower temperatures, limiting its reuse.

The component also offers environmental benefits during production. 3D printing reduces material use compared to conventional assemblies and improves recyclability by using only one material. Preliminary life cycle assessments suggest the solution could reduce total emissions by 25–30% per unit.

The AM2PC project ran from 2023 to 2025 with a total budget of DKK 10 million (approx. USD 1.45 million), funded by M-ERA.NET and Innovation Fund Denmark. Partners include Heatflow ApS, Danish Technological Institute, Open Engineering (Belgium), and Fraunhofer IWU (Germany).

The 3D-printed aluminium component acts as an evaporator, using a thermosiphon principle to remove heat without pumps or fans. In tests, the system achieved a cooling capacity of 600 watts—50% higher than the original target of 400 watts. This approach addresses the growing energy demand in data centers, especially as GPU power density increases.

“The power density in servers is increasing faster than ever before, and traditional air cooling is no longer sufficient,” said Paw Mortensen, CEO of Heatflow and AM2PC project lead. “With our two-phase solution, we can remove heat passively without pumps or fans, which significantly reduces the energy consumption for cooling.”

According to Simon Brudler, 3D-printing specialist and senior consultant at Danish Technological Institute, 3D printing in aluminium allows all functions to be integrated into a single part. This eliminates assembly points, reduces leak risk, and improves recyclability.

A key outcome of the project is the system’s ability to remove heat at temperatures between 60–80°C, making the waste heat suitable for district heating or industrial use without additional energy input. Traditional air cooling typically extracts heat at lower temperatures, limiting its reuse.

The component also offers environmental benefits during production. 3D printing reduces material use compared to conventional assemblies and improves recyclability by using only one material. Preliminary life cycle assessments suggest the solution could reduce total emissions by 25–30% per unit.

The AM2PC project ran from 2023 to 2025 with a total budget of DKK 10 million (approx. USD 1.45 million), funded by M-ERA.NET and Innovation Fund Denmark. Partners include Heatflow ApS, Danish Technological Institute, Open Engineering (Belgium), and Fraunhofer IWU (Germany).

Related tags: evaporator