Ecuador Shrimp Facility Implements Large-Scale CO2 Transcritical Refrigeration

A major shrimp processing facility in Ecuador has adopted a fully CO₂ transcritical refrigeration system from SCM Frigo S.p.A., marking a significant step toward sustainable and efficient industrial cooling. The installation demonstrates the potential of CO₂ technology to replace traditional refrigerants while optimizing energy use and reducing environmental impact.

System Overview

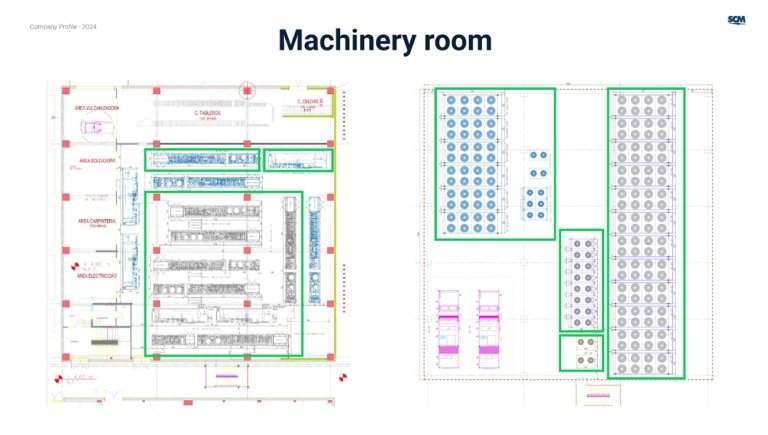

The refrigeration system is designed to meet the facility’s stringent cooling demands with a total installed capacity of 6 MW. Key components include:

- 46 medium-temperature (MT) transcritical compressors (1940 HP)

- 33 low-temperature (LT) compressors (1060 HP)

- 7 operational refrigeration units, optimized for process-specific cooling

- 26 industrial evaporators, ensuring uniform temperature distribution

- 12 gas coolers (8x800mm each) for efficient heat rejection

- 2 LT pump stations with 3500L vessels for precise liquid distribution

Key Innovations

The system incorporates advanced refrigeration technologies to enhance efficiency and sustainability:

- Mechanical Subcooling reduces flash gas formation, improving cooling capacity without extra energy consumption.

- Vapor Ejectors recover energy lost during pressure reduction, reducing compressor workload while maintaining stable operation.

- Hot Gas Defrost minimizes frost buildup and energy consumption while improving heat transfer efficiency.

- Heat Recovery Integration captures waste heat from the refrigeration cycle to preheat water, lowering overall energy demand.

Performance Metrics

The installation is designed for ultra-low and low-temperature applications, ensuring thermal stability across different process zones:

- Ultra-LT Evaporation (-45°C/-42°C): 1620 kW

- LT Evaporation (-32°C/-25°C): 1530 kW

- MT Direct Expansion (-5°C/-3°C): 460 kW

- MPG20% Brine System (+1°C): 640 kW

- Air Conditioning Water (+6°C): 1000 kW

- Heat Recovery Water (55°C/65°C): 1300 kW

- Total Gas Cooler Heat Rejection: 8300 kW

Industrial Refrigeration Impact

This installation, featuring a CO₂ transcritical refrigeration system from SCM Frigo S.p.A., is one of the largest of its kind in the region. Compared to conventional HFC-based systems, CO₂ technology offers:

- Lower Global Warming Potential (GWP = 1) by eliminating high-GWP synthetic refrigerants.

- Higher Thermodynamic Efficiency, particularly in low-temperature applications.

- Enhanced Energy Recovery, reducing the need for auxiliary heating.

- Improved Compliance with international F-Gas reduction policies.

The adoption of large-scale CO₂ refrigeration in industrial food processing sets a precedent for balancing performance, sustainability, and energy efficiency, reinforcing CO₂ as a scalable long-term solution for the industry.