27 June 2025

EVAPCO and CCCTC collaborate on 3D model of dry cooler

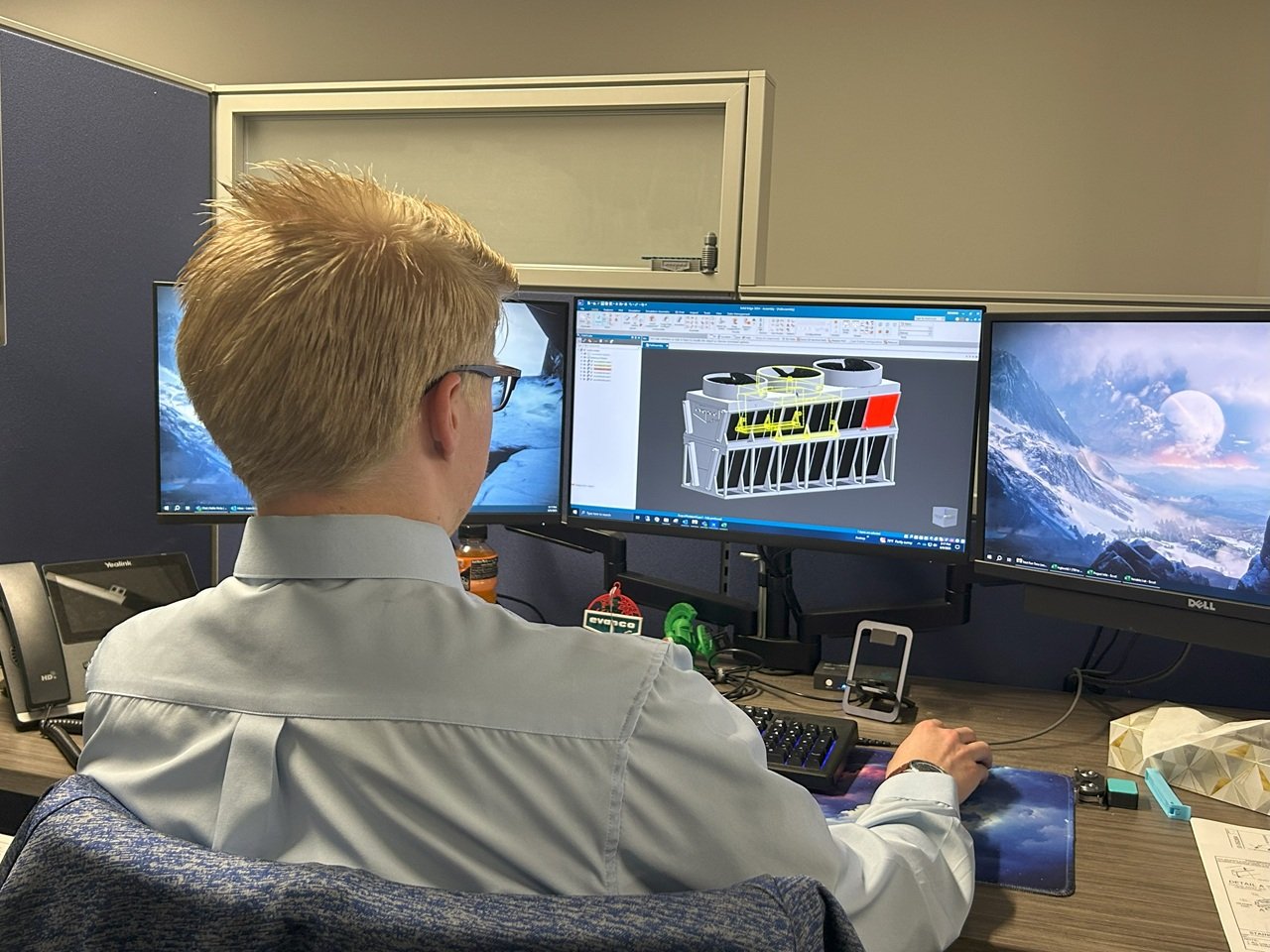

EVAPCO has partnered with the Carroll County Career & Technology Center (CCCTC) to support a student-led 3D modeling project based on the company’s eco-Air Series Double Stack Dry Cooler. The collaboration connected EVAPCO’s engineering team with CCCTC’s “Project Lead the Way” Engineering program, offering students a real-world design experience.

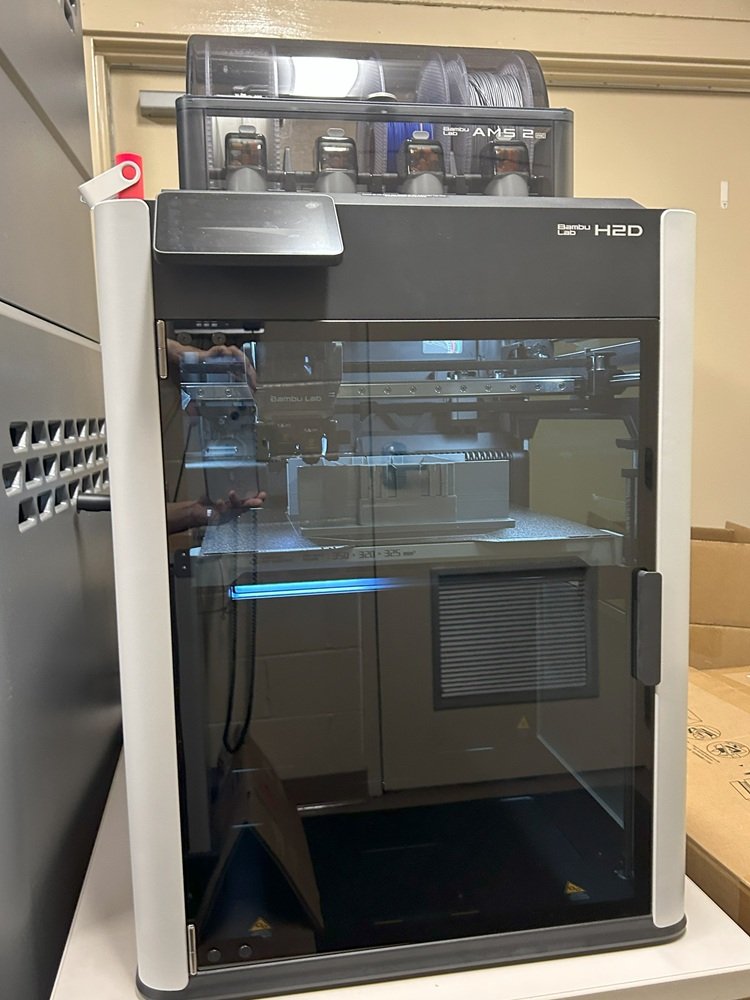

Under the guidance of instructors Scott Tobias, Jen Sanders, and Kristina Talley, students Jackson Rilley and Connor Tracy created a detailed .STL file of the dry cooler. The model, designed to reflect the cooling unit used in applications such as data centers and manufacturing facilities, was produced using 3D printing technology at EVAPCO headquarters.

The printed model was completed by Liam Bates, a Senior Drafter at EVAPCO and graduate of the same CCCTC program. The project emphasized skills in CAD design, geometric refinement, and interpreting industrial specifications.

EVAPCO plans to use the resulting 3D-printed model in marketing and educational settings including career fairs, conferences, and facility tours. The company highlighted the initiative as part of its broader outreach to local technical education programs.

“This partnership is about more than just a school project,” said Stephen Engelhardt, Design Group Manager of Industrial Refrigeration Product Development at EVAPCO. “It’s about building a pipeline of skilled, passionate young professionals who are ready to make an impact.”

Under the guidance of instructors Scott Tobias, Jen Sanders, and Kristina Talley, students Jackson Rilley and Connor Tracy created a detailed .STL file of the dry cooler. The model, designed to reflect the cooling unit used in applications such as data centers and manufacturing facilities, was produced using 3D printing technology at EVAPCO headquarters.

The printed model was completed by Liam Bates, a Senior Drafter at EVAPCO and graduate of the same CCCTC program. The project emphasized skills in CAD design, geometric refinement, and interpreting industrial specifications.

EVAPCO plans to use the resulting 3D-printed model in marketing and educational settings including career fairs, conferences, and facility tours. The company highlighted the initiative as part of its broader outreach to local technical education programs.

“This partnership is about more than just a school project,” said Stephen Engelhardt, Design Group Manager of Industrial Refrigeration Product Development at EVAPCO. “It’s about building a pipeline of skilled, passionate young professionals who are ready to make an impact.”