Frascold invests in a sustainable footprint

In the context of a path oriented towards increasingly sustainable innovation, Frascold – a leading player in the development, production and marketing of semi-hermetic compressors for the refrigeration and air conditioning industry – strengthens and consolidates its commitment, integrating an Environmental Management System that extends along the entire value chain. A philosophy of fair and lasting growth, shared at international level, with which Frascold aims at enhancing its processes and products, in order to reduce its ecological footprint. A systematic and preventive approach, based on the definition of specific company guidelines, on the planning of activities and on the measurement of performance, in compliance with ESG criteria and the territory in which Frascold operates.

“Sustainability is a fundamental and strategic asset for Frascold. Incorporating environmental governance into your Quality management system means actively pursuing responsible development at 360°, in a long-term perspective.” says Giuseppe Galli, CEO of Frascold, who then carries on “Frascold turns its attention to the entire life cycle of solutions, from design and production, to marketing and distribution, for the benefit of the entire supply chain. On the one hand, continuous investments in R&D have allowed us to create innovative natural refrigerant compressors, placing the company at the forefront of achieving international climate and energy targets. On the other hand, Frascold supports various initiatives aimed at making the plant more efficient and at improving the well-being of its workers.”

In detail, Frascold, at its Headquarters in the province of Milan, promotes the adoption of technological processes that combine superior performance with a lower carbon footprint. Among these, the optimisation of the production chain according to the principles of Lean Manufacturing, stands out, which aims at maximising the efficiency of flows and reduce waste. Starting from the assembly department, Frascold aims at standardising operational activities by associating the production of each family of compressors with a specific line. An optimal organisation, implemented thanks to a space designed to make all the materials easily available and identifiable. Improvement interventions which, in addition to simplifying the work of the operators also through ergonomically correct workstations, translate into advantages in terms of performance, effectiveness and safety. Visual management techniques are also applied within the production and warehouse sectors, where specific containers have been introduced which, once their content is exhausted, are returned to the supplier to be refilled, thus reducing the use of cardboard and plastic. A choice based on the principles of the circular economy which is combined with a lower use of natural resources, achieved thanks to the installation of a distiller for the recovery of the washing water used in the plants, in favour of an estimated annual saving of 300m3 of water, equivalent to 300 000L.

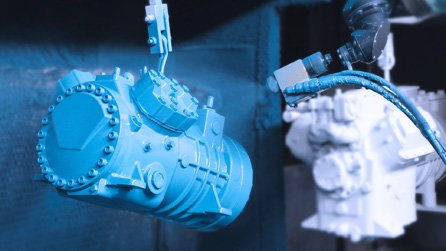

In addition, the Frascold Environmental Management System takes the form of greater attention to ordinary preventive maintenance. An example of this is the new eco-compatible refrigerant chiller, the result of the company’s will to further increase the efficiency of the internal test laboratory. This is a chiller designed for the operation of calorimeters and test benches, with Frascold compressors of the Magnetic series, ATEX certified, characterised by a cooling capacity of 350kW, for energy savings of +20% compared to a traditional model. Furthermore, the constant control of the solution makes it possible to monitor absorption and overall consumption, essential information also for the technical office, which analyses its endurance.

Lastly, for Frascold, environmental protection is reflected in the rationalisation of the use of energy resources, pursuing significant savings and the reduction of carbon emissions. In 2022, the Company built a photovoltaic system made up of a total of 3,500 panels which, after a year, generated significant benefits: a reduction of 600 tonnes of CO2, a production of clean and renewable electricity equal to 1.5 GWh, an average self-consumption greater than 80% and a coverage of the total annual requirement equal to 30%. Another concrete evidence of Frascold’s attention to contributing to the energy transition is the project scheduled for the next few months: the introduction of a new heat pump, with natural fluid and Frascold compressors, intended for heating and cooling the office building.

“At Frascold, the goals we achieved depend on everyone’s commitment and their value is primarily determined by the way we achieved them. A distinctive sign, thanks to which our Customers recognise us as a reliable and transparent partner” adds Franco Bonfiglio, Vice Chairman of Frascold, who concludes “We believe that, for conscious and ethical management, it is essential to define roles of responsibility at every level of the organisational structure, in order to guarantee all our personnel the information necessary to carry out their duties in respect of the ecosystem. To this end, it is necessary to promote a shared vision that can raise awareness and involve employees and suppliers, for a sustainable evolution based on shared goals.