gold partner

19 September 2025

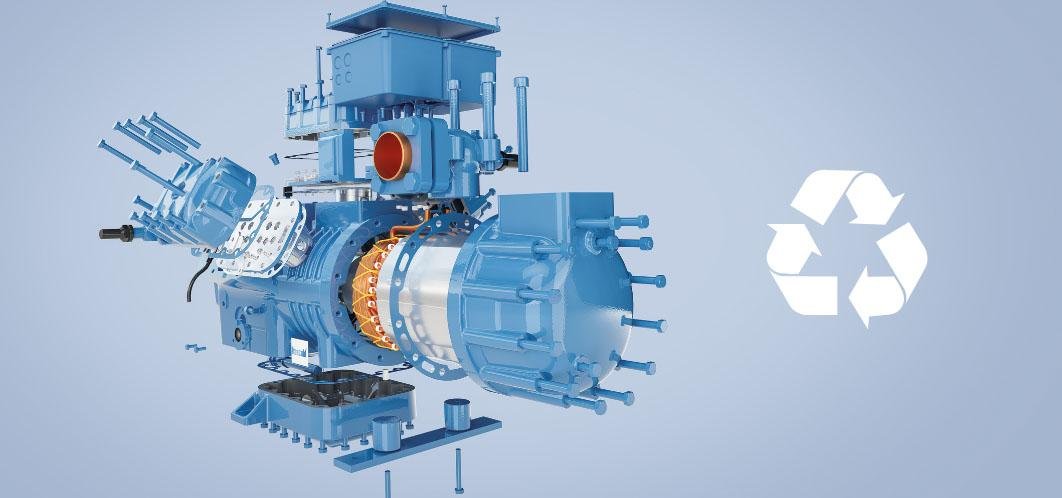

Frascold promotes sustainable compressor end-of-life management

Frascold has reiterated its commitment to sustainability by focusing on responsible practices during the End-of-Life (EOL) phase of compressors. The company aims to minimize environmental impact and enhance resource recovery through structured processes and services.

As part of its approach, Frascold encourages customers and partners to prioritize maintenance and repair over replacement. This extends component life, reduces waste, and lowers operational costs. To support this model, the company relies on a global network of Authorized Service Centers, staffed by specialists receiving ongoing training.

Frascold also provides a Spare Parts Software platform to simplify the identification and procurement of components. This tool improves maintenance operations and reduces downtime, contributing to longer equipment life cycles and less environmental strain.

When repair is no longer viable, Frascold ensures proper disposal and material recovery in line with environmental standards. Cast iron is sandblasted and remelted, steel is sent directly for remelting, and metals from electric motors—such as copper and aluminum—are recovered manually or as mixed metal. Brass and stainless steel are recycled into new components, while gaskets are disposed of as mixed waste at authorized facilities.

By managing compressor end-of-life responsibly, Frascold supports a more circular and efficient economy.

As part of its approach, Frascold encourages customers and partners to prioritize maintenance and repair over replacement. This extends component life, reduces waste, and lowers operational costs. To support this model, the company relies on a global network of Authorized Service Centers, staffed by specialists receiving ongoing training.

Frascold also provides a Spare Parts Software platform to simplify the identification and procurement of components. This tool improves maintenance operations and reduces downtime, contributing to longer equipment life cycles and less environmental strain.

When repair is no longer viable, Frascold ensures proper disposal and material recovery in line with environmental standards. Cast iron is sandblasted and remelted, steel is sent directly for remelting, and metals from electric motors—such as copper and aluminum—are recovered manually or as mixed metal. Brass and stainless steel are recycled into new components, while gaskets are disposed of as mixed waste at authorized facilities.

By managing compressor end-of-life responsibly, Frascold supports a more circular and efficient economy.

Related tags: Frascold

Related news

Frascold strengthens Competence Center team for enhanced technical ...

Frascold has reinforced its Competence Center with new appointments and a renewed structure, aiming to provide more effective technical support throughout the compressor life cycle.

The ...

30 Jan 2026

Frascold to showcase natural-refrigerant compressors at EuroShop 2026

Frascold will participate in EuroShop 2026 from February 22 to 26 in Germany, exhibiting in Hall 16, Stand E28. The company said it will present its full portfolio of compressors for natural re...

26 Feb 2026

Frascold launches NEXUS screw compressors for high-temperature heat...

Frascold has introduced its new NEXUS series of semi-hermetic screw compressors, developed specifically for high-temperature heat pump applications in industrial settings. The launch addresses ...

13 Jan 2026

Garrett wins China serial award for oil-free HVAC compressor for e-...

Garrett Motion Inc. said it has received its first serial award in the mobility sector for an oil-free, foil bearing-based centrifugal compressor, selected by Chinese commercial-vehicle HVAC integr...

25 Feb 2026

LU-VE appoints Michele Ampezzan CCO for Cooling and Components

LU-VE S.p.A., an air heat exchanger company listed on Euronext STAR Milan, has appointed Michele Ampezzan as Chief Commercial Officer (CCO) for both its “Cooling” (ventilated) and “Components” (sta...

27 Feb 2026

Danfoss posts record EUR 734m cash flow in 2025

Danfoss reported improved financial performance in 2025, citing record-high free operating cash flow after financial items and tax (before M&A) of EUR 734 million, up 57% from 2024. Total

today