The climate also needs to be right in the stands. GEA technology ensures a pleasant temperature of up to 21 degrees Celsius for the fans. And because the next game or another major event is never far away, the ice needs to hold up and must not thaw. After an ice hockey game, construction usually starts right away to set up for a concert, a basketball game or other events. The ice surface then disappears under 1,249 insulation panels for several hours or even days without thawing or deteriorating in quality. This is possible thanks to a real power-play combination provided by engineers, ice masters and the in-house technicians team.

CLIMATIC GfKK – Gesellschaft für Kältetechnik-Klimatechnik mbH was the main contractor for the multi-purpose arena project in Berlin. Technical Service Manager Martin Reichmuth explains the decision to go with GEA solutions and technologies: “It was the equipment’s efficiency that tipped the scales in GEA’s favor. The overall efficiency, flexibility, wide performance range, long service intervals and an extended, best-in-class warranty led to our selection.”

The Berlin arena refrigeration system works along the same principle as a refrigerator

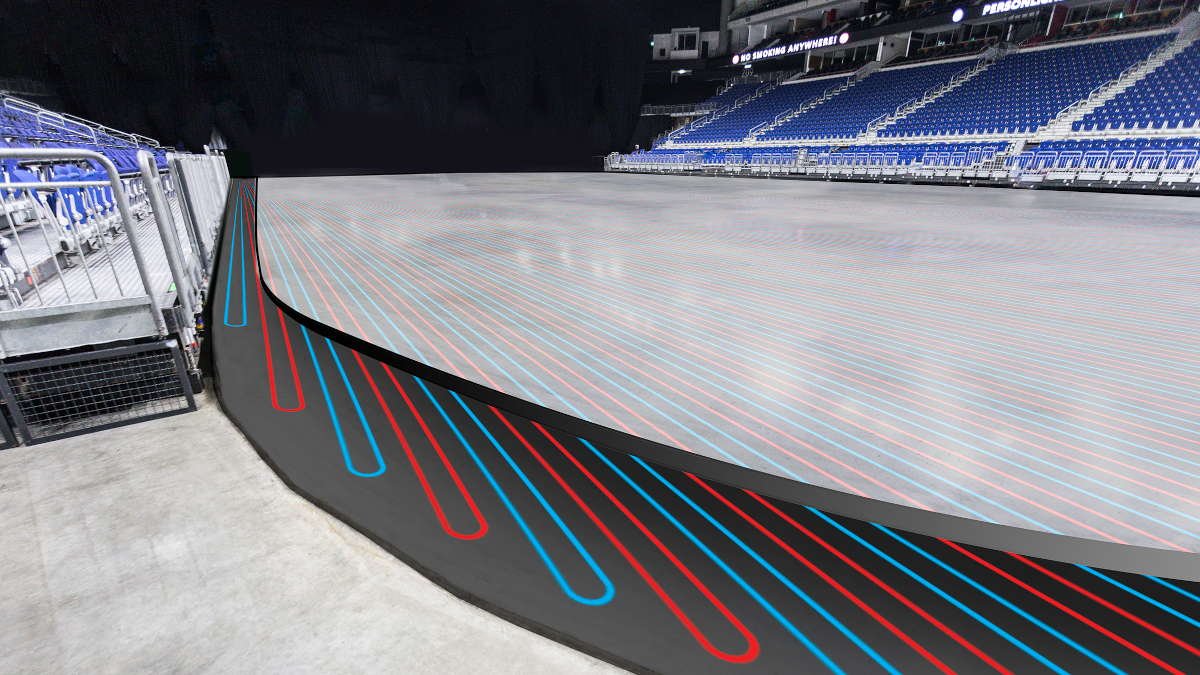

Today’s refrigeration systems are based on the principle of a closed refrigeration cycle. An NH₃/CO₂ (ammonia/carbon dioxide) cascade is installed in the Berlin arena. The secondary refrigerant is CO₂, while NH₃ is the refrigerant for the primary circuit. The refrigeration circuit’s main components are the compressor, the condenser, the expansion valve and the evaporator, the refrigerant pumps and the cooling tower.

First, the gaseous refrigerant is sucked in and compressed by the compressor, with the heat generated in this process being absorbed by the refrigerant. The heated refrigerant is fed into the condenser, where it cools down at constant pressure. In the process, the refrigerant condenses, becoming liquid. In the next step, the now liquid refrigerant reaches the expansion valve. Through this valve, the refrigerant expands to a low pressure level, thus reducing the temperature. In the final step, the refrigerant flows into the evaporator, where it is returned to a gaseous state. During this process, the heat required is extracted from the surrounding environment, which cools down as a result. So in fact, cold is not being made. It is simply the removal of heat. The refrigeration cycle then starts again with the transfer of the refrigerant into the compressor.

The interface of the two circuits is the evaporator/condenser, where the gaseous CO₂, which comes from the CO₂ separator, is liquefied and the liquid ammonia is evaporated. Pumps then feed the liquefied CO₂ into the pipes (secondary circuit) in the ice surface, where it absorbs heat and returns to the separator partially vaporized. The two circuits work in tandem.

GEA Grasso M packages

The sophisticated design and low parts complexity combine reliability and serviceability with high efficiency. This can save significant energy, service and other ongoing costs, reducing the total cost of ownership of the refrigeration system over its lifetime. On average, the M models consume three to five percent less drive energy than their screw compressor unit predecessors. As a result, they contribute to significant energy cost savings.Thanks to the high-performance motor (speed range from 1,000 to 4,500 rpm), the GEA Grasso M packages ensure top performance with maximum energy efficiency under all load conditions. In addition, the GEA Grasso M packages operate without an oil pump, giving refrigeration plant operators the dual benefit of lower energy and spare parts costs.

The screw compressor and drive motor are mounted on a horizontal oil separator, saving space and at the same time ensuring effective separation of the refrigerant from the oil. Thanks to its minimal oil throw rate (5 ppm) and low oil charge, maintenance costs are reduced – further bringing down the total cost of ownership.

At a glance – the highlights and technical features of GEA Grasso M packages for industrial refrigeration

- Maximum efficiency in the smallest possible space

-

Easy to service and low maintenance

-

Speed-controlled motor with a speed range of 1,000 to 4,500 rpm for high power capacities and efficiencies in part-load operation

-

Stepless power control via frequency converter and/or slide valve system

-

GEA Omni control with high-resolution 15.6" touch screen

-

GEA and the natural refrigerant ammonia

Ammonia is the most efficient and cost-effective natural refrigerant with a GWP of 0 and can generate 1.75 kW from 1 m³/h mass flow. In other words, it has a higher capacity, so less of it is required to produce the same output as alternative refrigerants. Another major advantage of climate-friendly ammonia is that, thanks to its thermodynamic properties, it can be used for both cost-effective cooling and heating. The COP (coefficient of performance) of a heat pump operating under typical conditions for a district heating network or for process heat below 100 degrees Celsius, for instance, is 40 percent higher than that of synthetic refrigerants. This translates to a 40-percent reduction in emissions, energy consumption and costs. Another significant advantage of ammonia is its long life, making it a great investment compared with other refrigerants. While other refrigerants may require customers to make a further investment for replacement or conversion to other refrigerants after ten years, an investment in ammonia is safe for the next 30 to 40 years, or even longer.