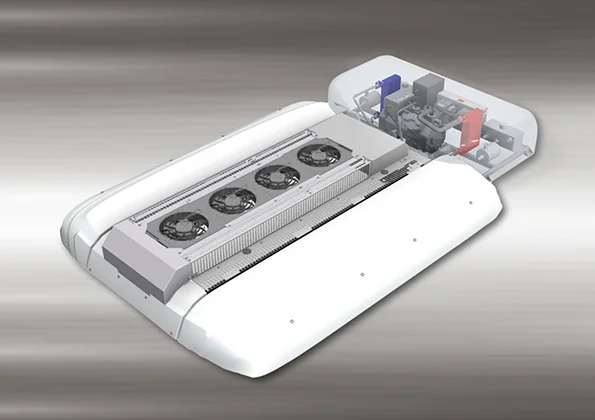

The new Konvekta CO2 heat pump 2.0 is a comprehensive and load-synchronous thermal management system. This system consists of the roof unit and two new Konvekta energy carrier modules. The desired auxiliary consumers can be heated or cooled at the same time with these new components. For example, the front box and convectors in the interior can be heated and the batteries can be cooled at the same time. This way the second generation Konvekta CO2 heat pump can be customised to fit all bus types.

Further energy requirements are achieved through:

- refrigerant CO2 (R744)

-

components developed in-house (e.g. heat exchangers)

-

Energy Collect (Heat recovery from heat-generating components = 15 -20% energy savings)

-

Konvekta control unit "CleverControl"

The energy consumption in comparison shows that of the possible variants of air conditioning an electric bus, the CO2 heat pump is the most energy-efficient.

Cost and environmental saving potential - energy consumption

The heat pump reduces energy consumption with zero emissions e.g. by 60% at -10°C in comparison to classic electric heating systems.

If you look at the entire year, including air conditioning, the energy requirement is reduced by more than 50%.

The Konvekta CO2 heat pump systems have been available on the market successfully as a series product since 2018. Already in use all over Europe - from Sweden to Great Britain to Italy, CO2 heating and air conditioning systems from Konvekta prove efficiency and economy every day. More than 1,300 buses and rail vehicles are currently in use with the alternative refrigerant CO2. Over 100 transport companies in over 40 countries use the systems in their bus fleets.

In the area of service and maintenance, CO2 results in considerable cost and time savings. This is because there is no need to recover or dispose of this refrigerant (R744) after any maintenance or repair work.

The simple and safe handling of the R-744 means that service times are reduced by more than half compared to the R-134a. Since R-744 is not a chemical refrigerant, it is not subject to the ChemKlimaSchutzVO.

The acquisition costs for the refrigerant per kg are over 90% lower.

Another benefit is the use of UltraLight technology. The extremely light and stable high-performance material forms the basis for holding all components, which makes exchanging components extremely easy. Filters, fans and other components are replaced in a few seconds.

This results in an overall saving in service costs of approx. 70%.