LAUDA, the world market leader for temperature control equipment and systems, has been manufacturing customer-specific refrigeration systems for pharmaceutical companies for more than 50 years. The company has now completed a cryogenic cooling system for use in a pharmaceutical freeze-drying plant. This enables pharmaceutical substances to be gently frozen at -80 °C. The order was placed by Martin Christ Gefriertrocknungsanlagen GmbH, one of the world's leading freeze-dryer companies with more than 70 years of experience in this field. Martin Christ relies on the expertise of LAUDA for the reliable provision of the deep-freeze environment. A Kryopac Secondary Circuit Unit from LAUDA Heating and cooling systems, the plant construction division of the temperature control specialist, which plans and manufactures exactly according to customer requirements, provides the requisite cooling capacity.

Precise temperature control for the freeze-dryer is provided by a LAUDA Kryopac Secondary Circuit Unit, which enables cryogenic reactions to be safely controlled. The possibility of individual temperature control of the shelves and the ice condenser is of great importance in this refrigeration system. But the Kryopac, a heat exchanger specially developed for the evaporation of liquid nitrogen, is the heart of the system. Liquid nitrogen boils at -196 °C and is therefore particularly suitable as a refrigerant for applications which require extremely low temperatures. Depending on the design of the Kryopac system, temperatures down to -115 °C are possible in the secondary refrigerant oil circuit. The -80 °C required for the freeze-dryer is therefore reached quickly and exactly to the degree. Liquid nitrogen is also a non-flammable refrigerant which is preferred not only by the end customer but also by the pharmaceutical industry in general. Other advantages include economic, safety and environmental aspects, such as low investment costs and lack of waste products. Depending on the specification of the application, the nitrogen requirement can be decreased by adapting the control system designed by LAUDA, thereby significantly reducing operating costs.

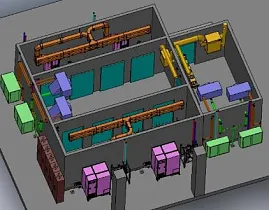

The heat technology of the Kryopac system is derived from the proven LAUDA Heat Transfer Units used by many customers. These produce a temperature-controlled liquid flow and are delivered as a compact, fully insulated, ready-to-connect system with a control cabinet. The benefit: There are no freezing problems in the heat exchangers here. Precise temperature control, compact design and high plant availability were particularly important for Martin Christ's customer. The LAUDA Kryopac Secondary Circuit Unit also meets these requirements without any problems.

The refrigeration system of the Kryopac system cools the shelves on which vessels filled with drugs are placed with a cooling capacity of 30 kW at -80 °C and freezes the pharmaceuticals in two and a half hours. Heat is supplied during evacuation, the removal of air by creating a vacuum. This results in a physical phenomenon called sublimation: The frozen water evaporates without liquefying. The drug is dried directly from the frozen state. The resulting water vapor is deposited on the ice condenser of the freeze-dryer in the form of ice crystals. The ice condenser is maintained at a temperature of -80 °C by the Kryopac system. A complete freeze-drying process typically takes 48 hours.

The Kryopac system was initially completely tested at LAUDA and then subjected to a further thorough inspection as a complete system at Martin Christ before the freeze-dryer was delivered to the enhas now completed a cryogenic coolin