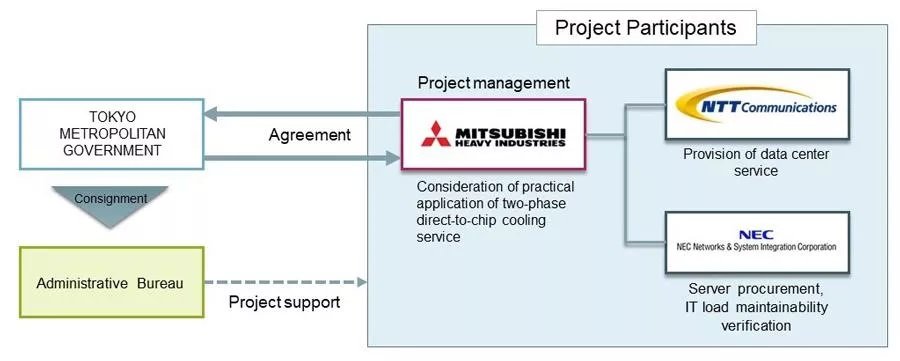

Mitsubishi Heavy Industries, Ltd. (MHI), NTT Communications Corporation (NTT Com), and NEC Networks & System Integration Corporation (NESIC) have announced the initiation of a demonstration test of two-phase direct-to-chip cooling systems for high-performance servers in operational data centers. This project, supported by the Tokyo Metropolitan Government's Bureau of Industrial and Labor Affairs, aims to reduce energy consumption and CO2 emissions by optimizing existing data center facilities without major modifications.

Addressing the Growing Demand for High-Performance Cooling

As generative AI and other advanced technologies proliferate, data centers face increased demands for high-performance processors like GPUs. These processors generate significant heat, requiring innovative cooling solutions. While new data centers can incorporate the latest technologies, retrofitting existing facilities poses challenges due to high capital investment costs. The two-phase direct-to-chip cooling system offers an effective and cost-efficient solution, enabling enhanced cooling performance while leveraging existing infrastructure.

Demonstration Test Overview

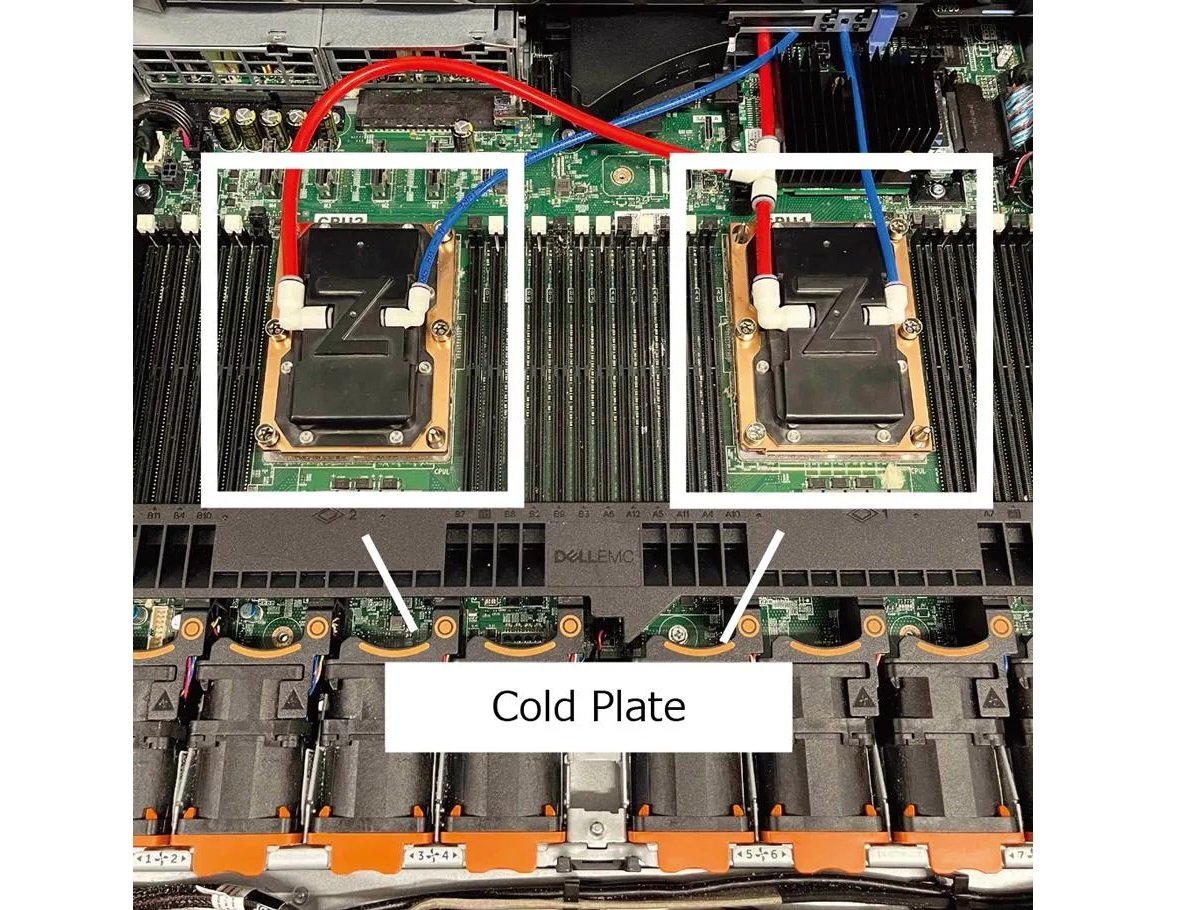

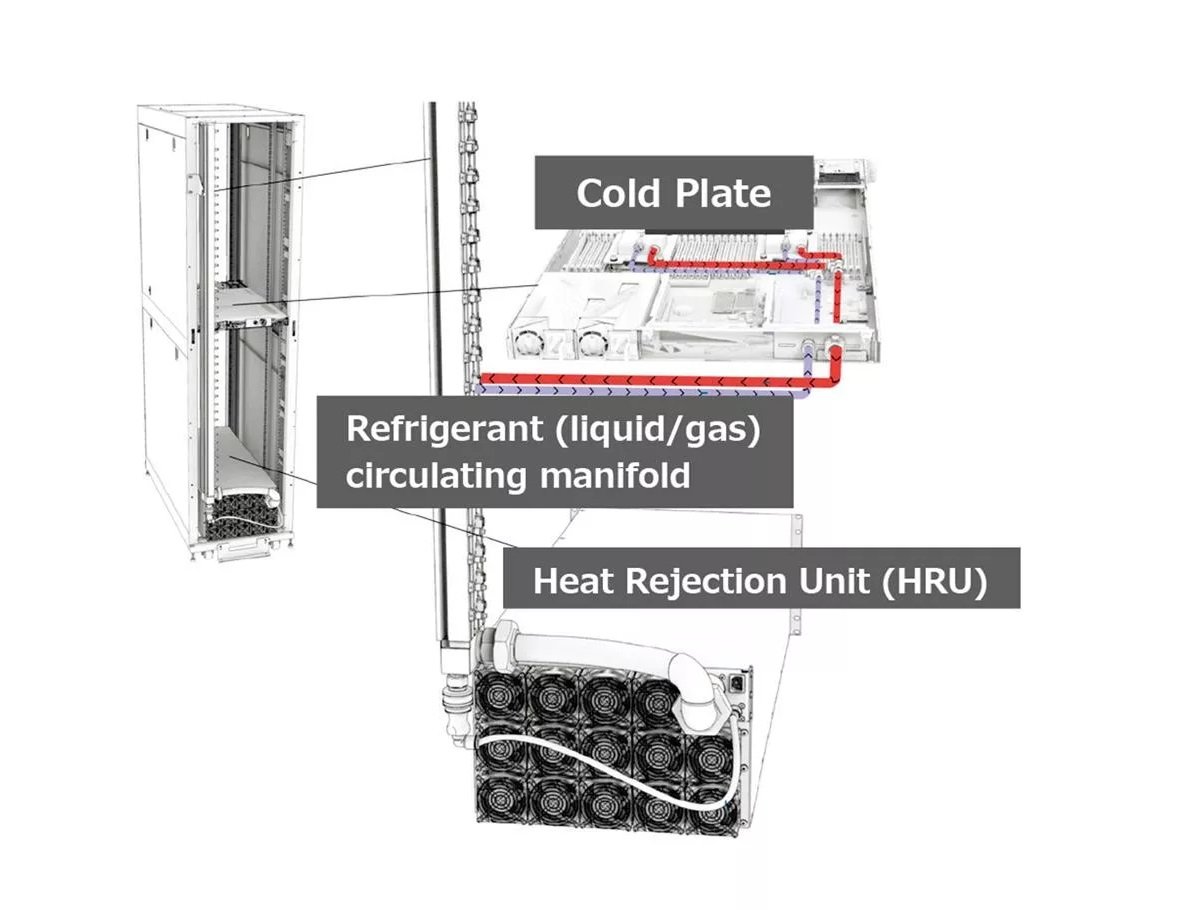

The project will be conducted at an air-cooled data center in Tokyo operated by NTT Com. The two-phase direct-to-chip cooling system from MHI uses an insulating refrigerant (not water), which circulates in liquid and gas phases to cool processors via cold plates inside the servers.

Key benefits include:

- Safety: The use of non-water refrigerants eliminates risks associated with leaks inside servers.

- Efficiency: Enhanced heat dissipation and autonomous refrigerant circulation optimize power efficiency.

- Flexibility: High-performance servers can be introduced into existing facilities without extensive upgrades.

Roles and Contributions

- MHI: Project management, provision of the two-phase direct-to-chip cooling system, and testing.

- NTT Com: Data center services and operational support.

- NESIC: Server procurement, IT load, and operational testing.

Future Prospects

This demonstration aligns with MHI’s commitment to delivering one-stop data center utility solutions, incorporating power supply units, cooling systems, and integrated control systems. By advancing Green ICT solutions, MHI aims to contribute to a carbon-neutral future and environmental sustainability.

NTT Com is also promoting green ICT through innovative solutions like Green Nexcenter®, supporting liquid-cooled server devices to meet the demands of AI and high-performance GPU technologies.

NESIC will leverage its system integration expertise to develop next-generation data center solutions, supporting carbon neutrality and global environmental conservation.

About Two-Phase Direct-to-Chip Cooling

This technology involves circulating an insulating refrigerant in liquid and gas phases to a cold plate on a processor, efficiently dissipating heat without the use of water. It offers a safe, efficient, and sustainable alternative to traditional cooling methods, particularly for high-performance servers.