Siemens Mobility UK Advances Sustainability with Remanufactured Compressors for Train Air Conditioning

Siemens Mobility UK, in partnership with Green Point UK, BITZER UK’s compressor services division, is revolutionizing train air conditioning maintenance through the use of remanufactured compressors. This initiative not only ensures optimal fleet performance but also aligns with Siemens Mobility’s commitment to environmental and sustainability goals.

To date, Green Point UK has remanufactured over 200 BITZER semi-hermetic compressors, including the high-efficiency 2FC-3.2Y-40S and ECOLINE 2FES-3Y-40S models. These critical components are used in HVAC systems for Class 185 and Desiro trains, operating across the UK, to maintain passenger comfort in all weather conditions.

A Sustainable Solution for Rail HVAC Systems

Siemens Mobility opted for high-quality remanufactured compressors to reduce waste and embodied carbon while maintaining cost efficiency and ensuring quick turnaround times. This decision reflects the company’s resource efficiency goals and commitment to sustainable practices.

Paul Hawkin, Siemens Mobility UK Service Delivery Manager, emphasized, “Our sustainability strategy extends beyond our factory walls. By choosing remanufactured compressors, we reduce the carbon and material footprint without compromising efficiency or quality. It’s a win-win for the environment, our customers, and society as we work to transform rail travel.”

Proactive Maintenance to Prevent Disruptions

Green Point UK processes compressors at its Milton Keynes facility, following a stringent global remanufacturing protocol that restores units to original BITZER factory specifications. Approximately 98% of compressors returned are suitable for remanufacturing, resulting in minimal waste.

The compressors are remanufactured at a planned point in their lifecycle, ensuring reliability and reducing the risk of in-service breakdowns. This proactive approach minimizes HVAC system downtime and maintains passenger comfort.

Will Pribyl, Green Point UK General Manager, noted, “Siemens Mobility UK’s forward-thinking approach ensures HVAC systems remain in top condition. It’s a model of intelligent asset management, reflecting the importance of cooling systems for both comfort and operational efficiency.”

Comprehensive Overhaul and Full Traceability

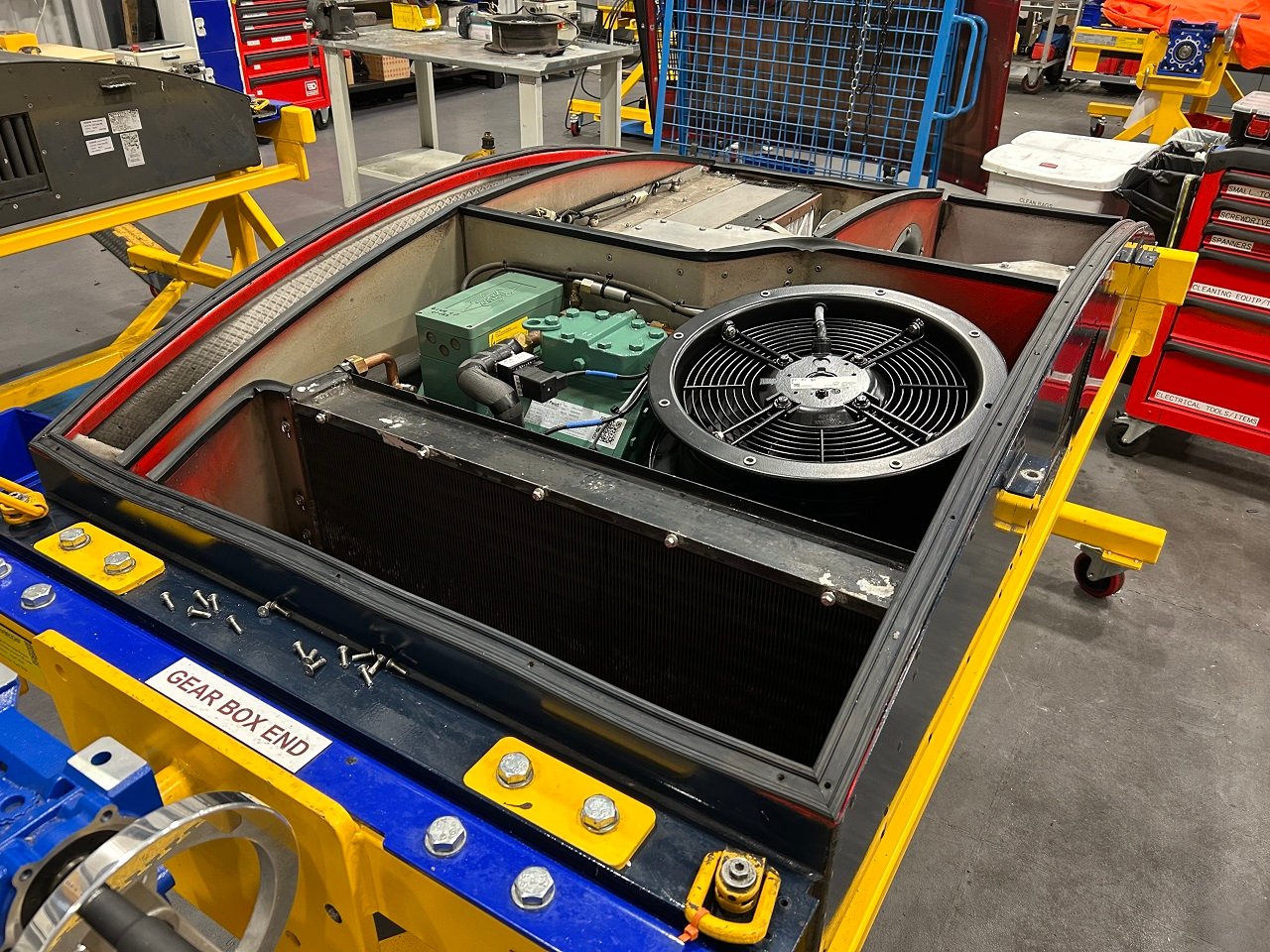

After remanufacturing, the compressors are returned to Siemens Mobility’s state-of-the-art Rail Village in Goole, a net-zero facility. They are reinstalled into HVAC modules as part of a comprehensive maintenance program, which also includes reconditioning air conditioning fans with new bearings.

Each remanufactured compressor retains its original BITZER serial number, along with a new Green Point UK serial, enabling full traceability throughout the equipment’s lifecycle. Green Point UK also maintains a stock of OEM replacement components, ensuring swift turnaround times.

Proven Technology for Sustainable Rail Operations

BITZER’s ECOLINE compressors, known for their high efficiency, broad application range, and reliability, form the backbone of this program. Compatible with low-GWP refrigerants, including HFC and HFO blends, they align with the industry's environmental goals.

Paul Hawkin highlighted the value of Green Point UK’s expertise, stating, “Being part of BITZER, they have access to original engineering data and parts, ensuring remanufacturing meets the highest standards.”