Lonigo, Vicenza province. Here Gruppo Maxi Di Srl has chosen Arneg to develop the entire food refrigeration system and to equip its new store with Arneg refrigerated cabinets.

Maxi Di’s goal was to create an environmentally-sustainable system, using a zero-impact gas, while at the same time ensuring the highest efficiency on the market. Once the objective was defined and a tailor-made solution was designed for the customer, Arneg decided to involve Carel in the project, looking to innovative modulating ejector technology to help meet these ambitious goals.

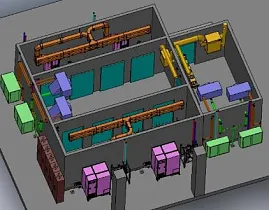

Being a medium-large store (2,300 square metres), it was decided to install an Arneg Booster transcritical compressor rack that uses CO2, carbon dioxide, as the refrigerant. Equipped with eight compressors, Carel electronics and ejectors that both fulfil in line with the latest market trends and the most recent regulations, the system supplies over 50 refrigerated cabinets - 44 medium temperature and 13 low temperature.

All thecabinets areequipped with Carel’s MPX PRO, the compact and flexible controller that effectively combines ease-of-use, stable control and energy savings.Two product lines are worth highlighting:the Arneg Arles line, here supplied in the semi-vertical version in the deli area, but also as a hot and cold showcase with “full view” glass, without metal supports, and the Arneg Velden line, the elegant semi-vertical cabinet for promotional sales.

Regarding the CO2 compressor rack, controlled by the pRack pR300T, three Carel EmJ modulating ejectors were used, for a total capacity of 185 kW. Compressor rack operation in ejector mode is an integrated solution that can reduce the cabinet superheat set point down to 0.5°K.

In this way, the evaporators work in a semi-flooded mode with a higher pressure set point, optimising compressor rack operation and reducing the energy consumption of the entire system.

This solution brings energy savings during the summer of up to of 25%, when the outdoor temperature is higher, but also in winter, via the heat recovery system that provides heating inside the building.

One essential feature of the ejector solution is continuous modulation that, through dedicated control algorithms, allows the system to continuously adapt to the variations in operating conditions that are typical of refrigeration systems.

The entire system is supervised by Arneg service through its IRIS Energy control centre, optimising performance, managing unforeseen events and energy wastage also thanks to the Carel boss supervisor, which acquires system data and organises these onto a dashboard for predictive maintenance.

“For years, Arneg has been working effectively with Carel, in a partnership based on mutual exchange. Research and technological innovation have allowed us over time to offer increasingly efficient and environmentally-friendly solutions, just like the one at the Famila supermarket in Lonigo”, commented Enrico Zambotto, Arneg’s Refrigeration Engineering Director. “As evidence of how much we are investing in this technology, we also now adopting ejectors in other installations, always using natural refrigerants, at numerous stores in Italy”.