The global heat exchanger market will reach USD 23.54 billion by 2030

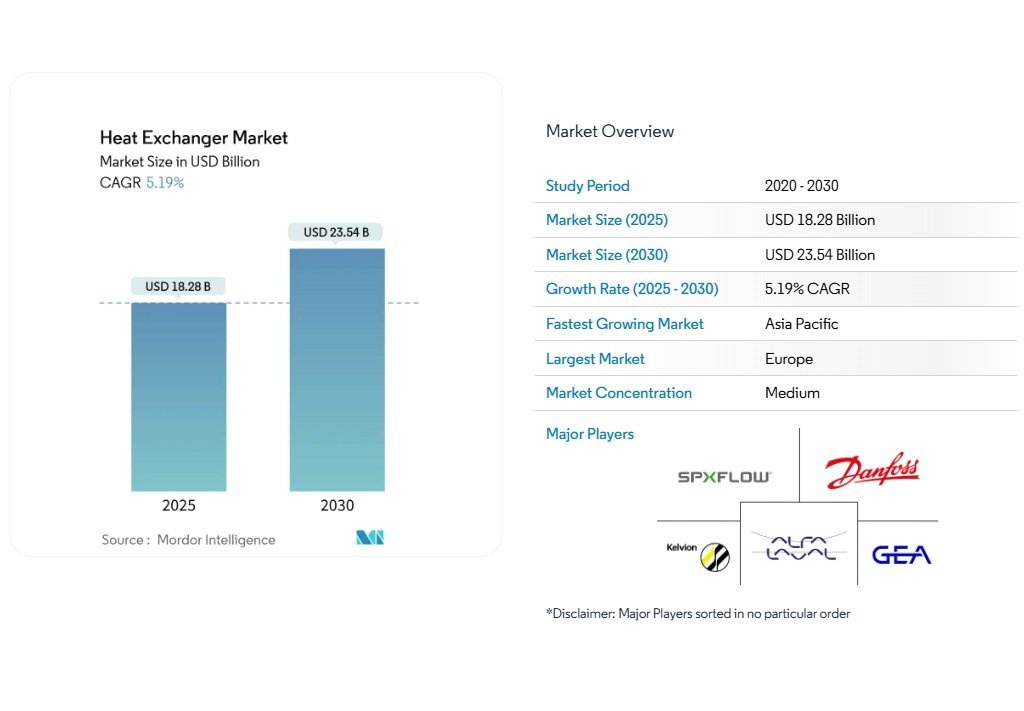

The global heat exchanger market is projected to grow from USD 18.28 billion in 2025 to USD 23.54 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.19%, according to a new report by Mordor Intelligence. This growth is driven by rising demand across oil and gas, HVAC, power generation, chemical, and food processing industries, where improving energy efficiency and operational performance remains a key priority.

Increasing adoption of compact and corrosion-resistant heat exchangers is noted across process industries. Developments in materials such as stainless steel, titanium, and nickel alloys are contributing to enhanced durability and performance. Modular and custom-designed units are also gaining traction for their adaptability in diverse industrial applications.

The market is witnessing significant demand from LNG projects, where cryogenic heat exchangers are essential for liquefaction, regasification, and storage processes. In parallel, district cooling systems are expanding in regions such as the Gulf and Southeast Asia, boosting deployment of plate and frame heat exchangers in HVAC systems due to their compact size and thermal efficiency.

Manufacturers are introducing advanced designs like micro-channel and printed circuit heat exchangers, offering improved thermal transfer and space optimization. Governments and industries are increasingly investing in systems that recover waste heat to reduce overall energy consumption.

Key players in the market include Alfa Laval AB, Kelvion Holding GmbH, Danfoss A/S, API Heat Transfer Inc., Hisaka Works Ltd., Xylem Inc., SPX Flow Inc., GEA Group AG, and HRS Heat Exchangers Ltd.

The report provides detailed segmentation by type, material, flow arrangement, and end-use industry, along with insights into competitive strategies and regional trends.