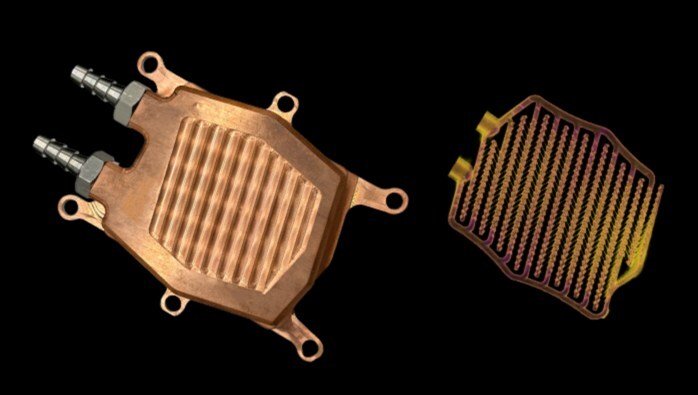

Alloy Enterprises has introduced a copper direct liquid cooling (DLC) solution aimed at addressing rising power densities in AI server racks. The company’s proprietary Stack Forging process enables improved thermal management as rack power densities surpass 120 kW.

According to the company, the Stack Forging process allows for targeted liquid cooling at high heat load areas, up to 10 times reduction in pressure drop, and single-piece component construction that eliminates common leak points. The new copper components complement Alloy’s existing aluminum solutions.

“With 600 kW racks on the horizon, the shift to liquid cooling is no longer optional—it’s mission-critical,” said Ali Forsyth, PhD., CEO and Co-founder of Alloy Enterprises. “We now deliver industry-leading thermal performance in both aluminum and copper, enabling higher rack densities, significant cost savings and greater sustainability.”

Alloy’s copper DLC components meet ASHRAE standards for chemical compatibility and are designed to support next-generation high-performance computing and dense AI workloads. The solution enables the use of 44 °C (111.2 °F) water and smaller pumps, eliminating the need for refrigerated HVAC systems. The company reports up to 23% reduction in energy consumption for data centers.

Alloy highlights benefits for hyperscalers and colocation providers, including improved power usage effectiveness (PUE), higher compute density, and reduced total cost of ownership. All aluminum and copper scrap generated in manufacturing is fully recycled.

“Alloy's copper line is already showing promising results in early customer deployments,” Forsyth added. “These components are hitting target thermal resistance thresholds while maintaining exceptional pressure drop performance, even in the most demanding rack configurations.”

The company is now shipping copper DLC cold plates and thermal components.