Automated Logic’s OptiFlex line of building controls for the WebCTRL building automation system continues to expand and evolve to support the most demanding control applications. Built for connectivity and adaptability, the OptiFlex family of fully programmable, IP-based controls helps facilities staff provide comfort, control and energy savings in buildings.

The OptiFlex controls line includes a comprehensive line-up of routers and gateways as well as building, equipment and zoning controls. New central plant solutions, are now available, including the OptiFlex PlantCTRL controller, which coordinates the management of central plant equipment including chillers, pumps and towers, and the OptiFlex chilled water system optimizer, which continuously delivers optimization and control of chilled water systems. These solutions can be used alone or together to help reduce energy consumption while improving occupant comfort levels in buildings.

With ongoing enhancements, the OptiFlex controller product line continues to deliver powerful, innovative features at the edge, including:

- Dual IP ports for network redundancy;

- 10/100/1000 ethernet port speeds;

- Support for daisy chain, ring, home run and hybrid IP network topologies;

- Built-in failsafe relay for IP network integrity;

- Built-in network diagnostics and analytics;

- BACnet/IP support from the building to the zone level;

- Support for IP protocols - IPv4, IPv6, Ethernet and BACnet/SC;

- Support for industry protocols - BACnet, Modbus, MQTT, N2 Open, SNMP and KNX;

- Graphically programmable in EIKON tool;

- Built-in Fault Detection and Diagnostics (FDD);

- ASHRAE Guideline 36 compliant control algorithms; and

- BACnet Testing Labs (BTL) certified.

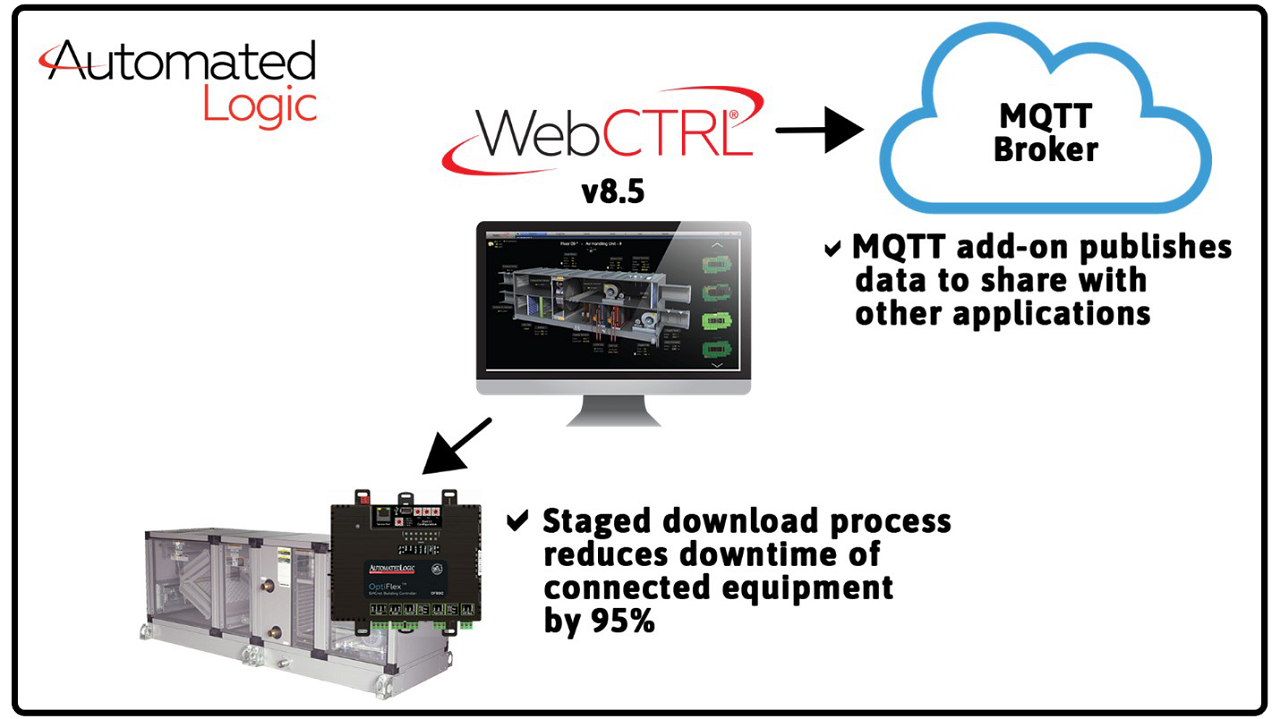

Automated Logic announced its latest software release for the WebCTRL building automation system, delivering message queuing telemetry transport (MQTT) integration capabilities and efficient staged controller downloads. These enhancements provide building owners and operators with more connectivity options, help them future-proof their building automation and control networks and help technicians provide better customer service.

With MQTT’s standard lightweight messaging protocol for IoT, Automated Logic’s optional MQTT add-on makes it fast and easy to publish data from the WebCTRL Building Automation System (BAS) to an MQTT broker - a standard component in cloud environments. BAS data is automatically formatted according to the Sparkplug B specification for MQTT and enriched with deep context from the BAS, including semantic tags. This rich data is used by other enterprise-level applications to inform business decisions.

The new WebCTRL v8.5 software also includes an efficient staged download process for upgrading controller firmware. While traditional downloads disrupt HVAC equipment operation throughout the entire download, the new staged process splits the download into discrete steps, which reduces downtime of the connected HVAC equipment. The downtime can be independently and proactively scheduled for non-critical times to minimize disruption.