Danfoss has introduced new features for its VLT HVAC Drive FC 102, aimed at improving the performance of air handling units (AHUs) and rooftop units (RTUs) within Building Management System (BMS) environments. The updates focus on simplifying installation, improving energy efficiency, and supporting reliable system operation.

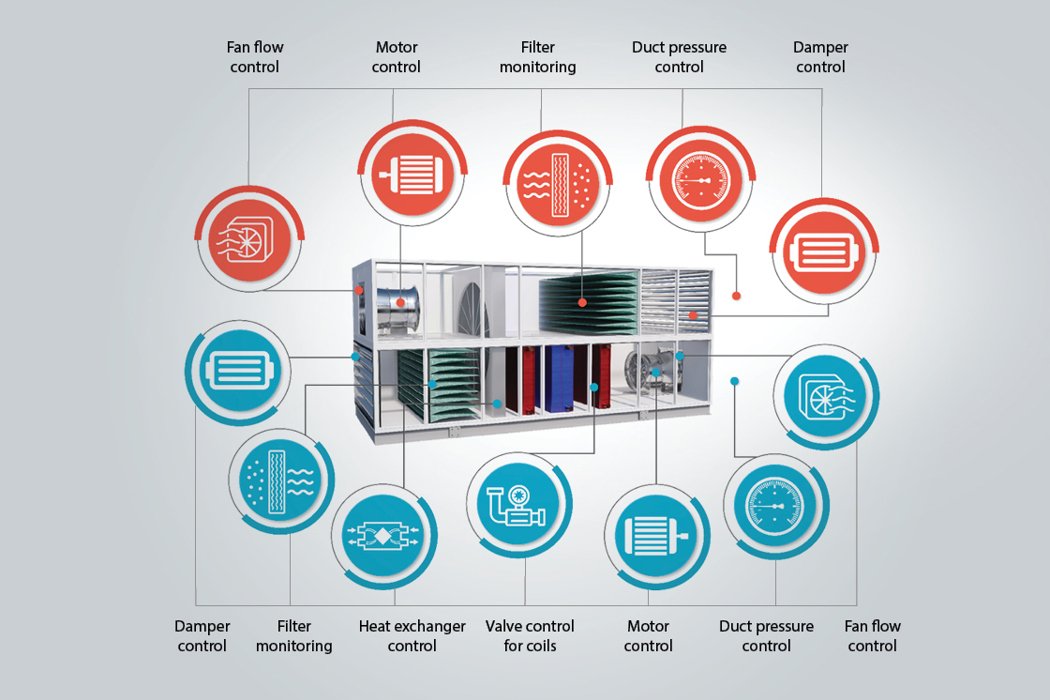

The FC 102 now integrates edge computing capabilities that combine intelligent control and operational data to optimize HVAC unit performance. As a "Drive as Controller" or "Drive as Sensor Hub", the VFD supports precise airflow adjustment based on real-time demand, enhancing both energy efficiency and indoor comfort.

The system interacts with sensors to monitor temperature, pressure, humidity, CO2 levels, and volatile organic compound (VOC) air quality. It continuously adjusts ventilation fan speeds based on real-time pressure data, which contributes to energy savings and documents operation efficiency in compliance with the EN16798 standard.

One FC 102 drive can monitor up to four AHU filters at once, enabling condition-based maintenance. Pressure sensor signals help detect filter status, issuing timely warnings when replacements are needed to maintain optimal performance and air quality. This built-in intelligence reduces the need for external devices, lowering system complexity and installation costs.

Connectivity features include support for IoT protocols such as MQTT and various fieldbus technologies. This ensures smooth communication with BMS platforms and enables the FC 102 to deliver real-time operational data, energy consumption insights, and early warnings of potential issues.

By integrating smart monitoring and control features, the updated VLT HVAC Drive FC 102 supports efficient and sustainable HVAC operations in both current and future building systems.