bronze partner

27 April 2023

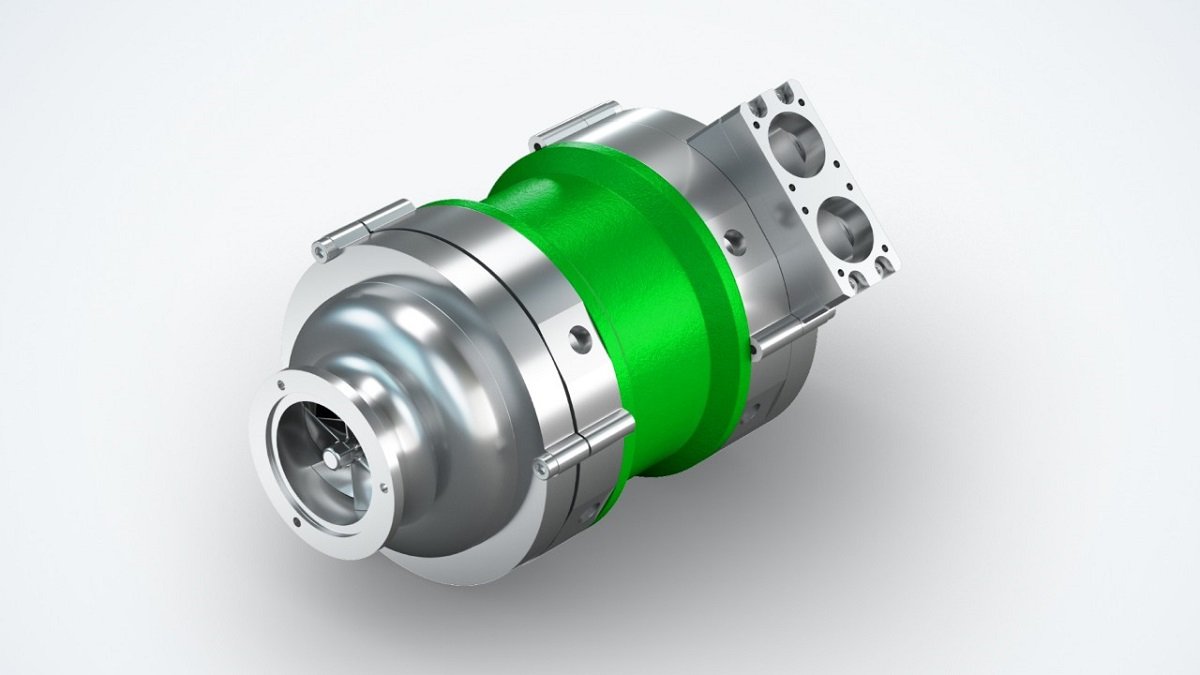

ebm‑papst's compact high-speed turbo compressors

ebm‑papst is expanding its product portfolio to include turbo compressors for different air and gas mixtures. These turbo compressors are used in heat pumps, self-contained drinking water systems and gas supply systems for fuel cells, for example. All components, from the drive motor to the compressor impeller and the newly developed oil-free high-speed bearings, are coordinated to suit the specific application.

High performance in a small installation space

Designed as a platform solution, individual compressors with outputs from 1 to 45 kW can be quickly assembled and different refrigerants, air and other gas mixtures can be compressed without oil. Thanks to their high speeds, the turbo compressors are very compact compared to conventional solutions, operate vibration-free and do not require any lubricating oil. This is of interest wherever gas purity is required. The gas bearing, which is not subject to contact or friction during operation, not only achieves a long service life but also has impressively low noise levels.

Tailor-made compressor platform

The new compressor platform enables a wide range of different applications to be operated economically. By combining different impeller sizes and blade geometries, it enables optimum aerodynamic adaptation to the application. This means that, depending on requirements, the impellers can be matched to the required mass flow or pressure ratio and the working gases used, such as air or R290.

First prototypes already in use

The P1 (1 kW) and P2 (2.8 kW) platforms are already available as prototypes and are also in use in customer applications. Series production processes were already considered in the concept phase, which will contribute to a competitive cost structure in future series production. With the help of the technical center currently under construction at the main site in Mulfingen, the first small series will start as early as the beginning of 2024. Series production, which is planned from 2026, is aiming for volumes significantly higher than one hundred thousand units per year and platform size.

High performance in a small installation space

Designed as a platform solution, individual compressors with outputs from 1 to 45 kW can be quickly assembled and different refrigerants, air and other gas mixtures can be compressed without oil. Thanks to their high speeds, the turbo compressors are very compact compared to conventional solutions, operate vibration-free and do not require any lubricating oil. This is of interest wherever gas purity is required. The gas bearing, which is not subject to contact or friction during operation, not only achieves a long service life but also has impressively low noise levels.

Tailor-made compressor platform

The new compressor platform enables a wide range of different applications to be operated economically. By combining different impeller sizes and blade geometries, it enables optimum aerodynamic adaptation to the application. This means that, depending on requirements, the impellers can be matched to the required mass flow or pressure ratio and the working gases used, such as air or R290.

First prototypes already in use

The P1 (1 kW) and P2 (2.8 kW) platforms are already available as prototypes and are also in use in customer applications. Series production processes were already considered in the concept phase, which will contribute to a competitive cost structure in future series production. With the help of the technical center currently under construction at the main site in Mulfingen, the first small series will start as early as the beginning of 2024. Series production, which is planned from 2026, is aiming for volumes significantly higher than one hundred thousand units per year and platform size.

Related news

Secop introduces KL-CNQX tropical compressors for propane cabinet s...

Secop has launched new tropical KL-Series compressors, including the KL-CNQX, targeting the next generation of light commercial cabinets using environmentally friendly refrigerant propane. The comp...

02 Mar 2026

Trane launches R290 air-to-water heat pumps for EMEA and ANZ

Trane (a brand of Trane Technologies) has launched two air-to-water heat pumps using R290 refrigerant: FLEX N HP and ARIES N HP. The company said the new units expand its R290 portfolio for custome...

26 Feb 2026

Daikin launches full R-290 range up to 2,000 kW

Daikin has introduced a complete R-290 (propane) product range covering capacities from 17 to 2,000 kW (approx. 58,000 to 6.82 million BTU/h). The portfolio includes two families: the EWA(Y)K-CZ mo...

03 Mar 2026

Sanhua Introduces SD2 VSD Extension for Commercial and Industrial H...

Sanhua has unveiled its new SD2 Variable Speed Drive (VSD) Extension, expanding its portfolio of high-performance drive solutions for commercial and industrial heating, ventilation, air conditionin...

10 Dec 2025

Danfoss launches DST P070 pressure sensor for compact HVAC systems

Danfoss Sensing Solutions has introduced the DST P070, a compact pressure sensor developed for heat pumps and other HVAC applications with limited installation space. The sensor is designed to supp...

17 Dec 2025

Copeland launches ZF/ZFI 10–20HP scroll compressors for Asia cold c...

Copeland has introduced its ZF/ZFI 10–20HP scroll compressors and related solutions for low-temperature cold chain applications in Asia. The company said the product line is designed to support coo...

05 Mar 2026