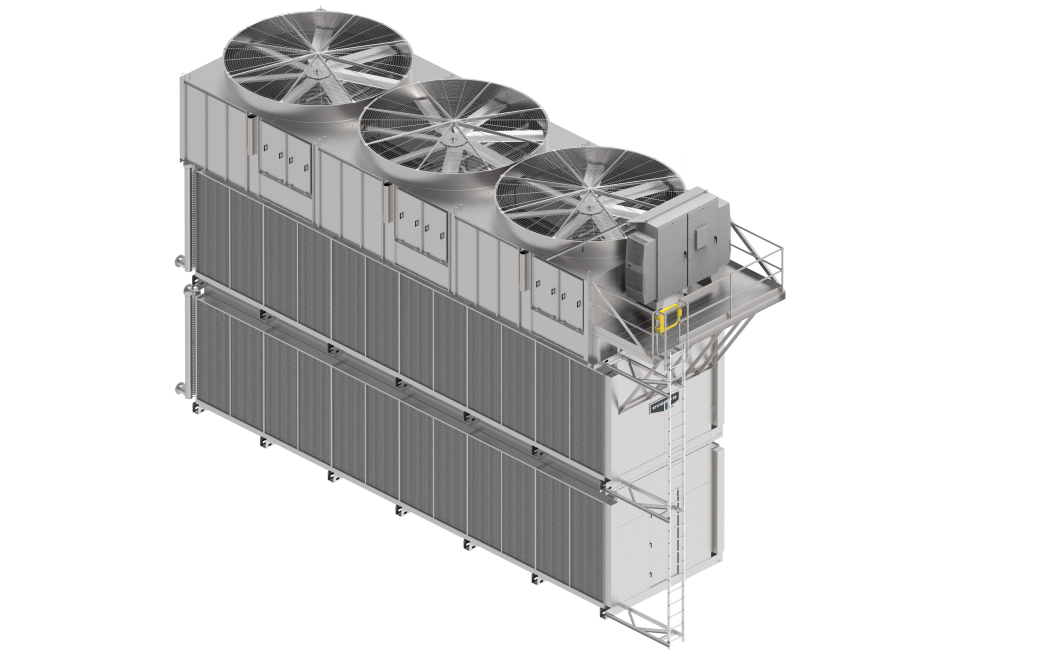

EVAPCO has introduced the eco-Air Series APEX Dry Fluid Cooler, the newest addition to its eco-Air Series and an evolution of its high density double stack product line. The company positions the unit for modern, high-density data centers and other mission-critical environments, as well as data center and industrial process applications, where higher capacity and lower footprint builds are required and water availability is difficult to find.

According to EVAPCO, the APEX is engineered to maximize dry heat rejection for a given footprint and to reduce the total quantity of units required compared with the eco-Air Double Stack, reducing installed footprint on large projects. The APEX is factory assembled and CTI certified for thermal performance, and it comes with EVAPCO SelectTech factory-mounted and tested controls, described as a plug-and-play solution.

EVAPCO states that its eco-Air Series units are 100% fully rated for dry performance, tested per CTI ATC-105DS, and supplied with EVAPCO’s 100% thermal performance guarantee. The company describes the APEX as the highest-capacity factory-assembled CTI Certified dry cooler on the market, with a CTI certified nominal heat rejection capacity of 9,060–11,490 MBH (approx. 2,655–3,367 kW).

In its operating description, EVAPCO says hot process fluid enters the inlet header connections, heat dissipates through the coil tube surface and fins, and ambient air is drawn over the coil surface by a top-mounted fan. Heat transfers to the air and discharges to the atmosphere, and cooled process fluid exits through the outlet header connections.

Standard and optional construction details listed by EVAPCO include a Type 304 stainless steel casing and structure (with G-235 galvanized steel and Type 316 stainless steel as options), Type 304L stainless steel coil tubing in compliance with ASME B31.5 (Type 316 optional), optional hydrophilic lacquer fin coating, belt drive NEMA motors with sealed bearings, and a SelectTech UL Type 4 PLC/VFD control panel with factory-wired DPDT vibration switches. Maintenance features listed include an external platform with ladder, hinged doors for access, internal drive access platforms, optional internal ladder, and motor access panels with optional motor davits.