FLOW system is used both for remote devices as well as plug-ins. It is a new eco-friendly solution, the properties of which allow you to improve the parameters of the equipment, reduce the environmental impact of your installationand most importantly, cut the costs.

HEAT MANAGEMENT

The FLOWsystem provides you with the possibility to manage the heat generated by the equipment, either to transfer it to a different place or reuse in a diffrent installation.

OPTIMAL EFFICIENCY

Using the FLOWsystem allows you to maintain even condensation levels and as a result you are able to reach reach stable cooling efficiency in the whole line of appliances.

SAVINGS

Once integrated with other systems (AC, C/HEAT, etc.) the FLOWsystem significantly reduces the operating costs of the whole store.

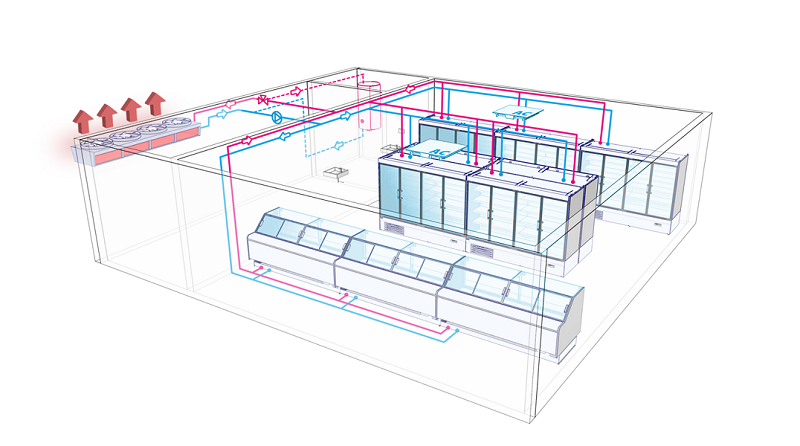

The FLOWsystem waterloop solution is the latest innovation by JBG-2, that allows you to easily manage the heat generated by the refrigerating appliances.

The system efficiently transfers the heat from the store area to a desired place, but also provides the possibility to reuse the heat in other store installations.

The FLOWsystem is an easy, cost efficient and ecological way to reach instant savings on the store’s operating costs, regardless if it works independently or is integrated with other installations.

The FLOWsystem is designed to suit every type of store. A small convenience outlet or discount store equipped with plug-in appliances. With a simple Plug-In to Plug-In FLOW adaptation can easily provide a significant ammount of savings with relatively low investment costs.

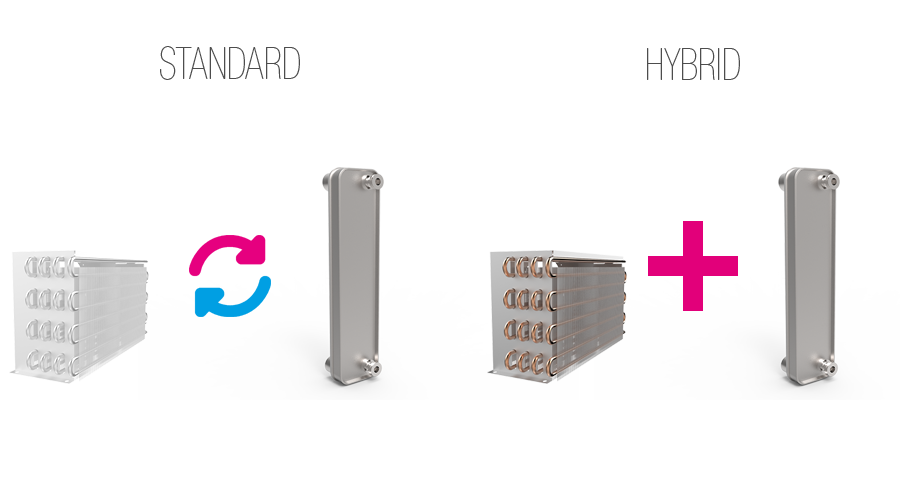

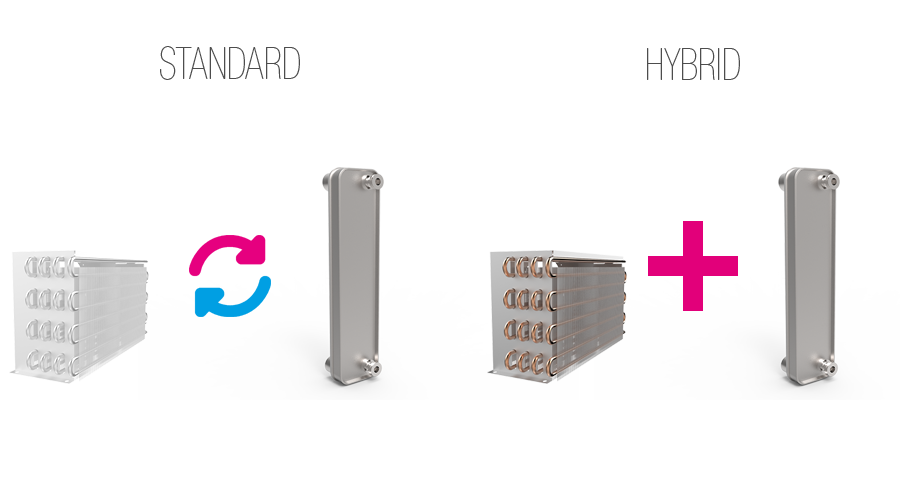

The main function of the FLOWsystem is to collect the heat emitted by the appliance, rather than allow it to simply be released into the ambient air. The element of the cooling unit responsible for giving out the heat from the inside of the appliance is the condenser. The FLOW adaptatnion of a refrigerating appliance mainly concerns the condenser and can be carried out in two versions. The STANDARD or the HYBRID.

In the STANDARD version the condenser is replaced with a plate heat exchanger, that becomes the main component responsible for the heat extraction in the cooling unit. The plate heat exchanger is also connected to the FLOW waterloop system, where with the use of a designated piping system, the heat can be trasfered to a desired location.

In the HYBRID version the plate heat exchanger is added to the cooling instalation without removing the condenser. In this version two components, the exchander and condenser, are both respondible for exctracting the heat from the appliance. Firstly the heat plate exchanger gathers the heat to the waterloop system. The residual heat travels to the condenser and is extracted to the ambient air. This provides more flexibility and safety than the STANDARD version.

In every case the FLOWsystem is individually tailored to the customers’ requirements and the store’s design. The choise of a suitable Dry Cooler package and piping system diameters, adapting the air conditioning system and a proper calibration by a specialist are necessary for the FLOWsystem to work efficiently.

For each set of appliences to be connected to the FLOWsystem, the Dry Cooller package is individually chosen depending on the total cooling power of all of the appliances to be located in the store.

The FLOWsystem can provide you with instant benefits simply by reducing the heat emmission in the store. You can increase the benefits by linking the FLOWsystem with other store installations like air and water heaters or the lighting system.

With a smart management system of every store installation you can arrive at the synergy effect that can give you significant overall savings on the total operating costs.

The FLOWsystem waterloop solution is the latest innovation by JBG-2, that allows you to easily manage the heat generated by the refrigerating appliances.

The system efficiently transfers the heat from the store area to a desired place, but also provides the possibility to reuse the heat in other store installations.

The FLOWsystem is an easy, cost efficient and ecological way to reach instant savings on the store’s operating costs, regardless if it works independently or is integrated with other installations.

The FLOWsystem is designed to suit every type of store. A small convenience outlet or discount store equipped with plug-in appliances. With a simple Plug-In to Plug-In FLOW adaptation can easily provide a significant ammount of savings with relatively low investment costs.

The main function of the FLOWsystem is to collect the heat emitted by the appliance, rather than allow it to simply be released into the ambient air. The element of the cooling unit responsible for giving out the heat from the inside of the appliance is the condenser. The FLOW adaptatnion of a refrigerating appliance mainly concerns the condenser and can be carried out in two versions. The STANDARD or the HYBRID.

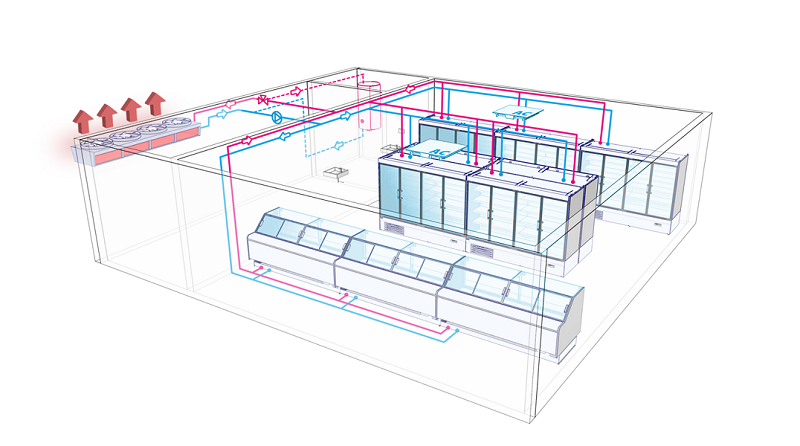

The FLOWsystem waterloop solution is the latest innovation by JBG-2, that allows you to easily manage the heat generated by the refrigerating appliances.

The system efficiently transfers the heat from the store area to a desired place, but also provides the possibility to reuse the heat in other store installations.

The FLOWsystem is an easy, cost efficient and ecological way to reach instant savings on the store’s operating costs, regardless if it works independently or is integrated with other installations.

The FLOWsystem is designed to suit every type of store. A small convenience outlet or discount store equipped with plug-in appliances. With a simple Plug-In to Plug-In FLOW adaptation can easily provide a significant ammount of savings with relatively low investment costs.

The main function of the FLOWsystem is to collect the heat emitted by the appliance, rather than allow it to simply be released into the ambient air. The element of the cooling unit responsible for giving out the heat from the inside of the appliance is the condenser. The FLOW adaptatnion of a refrigerating appliance mainly concerns the condenser and can be carried out in two versions. The STANDARD or the HYBRID.

In the STANDARD version the condenser is replaced with a plate heat exchanger, that becomes the main component responsible for the heat extraction in the cooling unit. The plate heat exchanger is also connected to the FLOW waterloop system, where with the use of a designated piping system, the heat can be trasfered to a desired location.

In the HYBRID version the plate heat exchanger is added to the cooling instalation without removing the condenser. In this version two components, the exchander and condenser, are both respondible for exctracting the heat from the appliance. Firstly the heat plate exchanger gathers the heat to the waterloop system. The residual heat travels to the condenser and is extracted to the ambient air. This provides more flexibility and safety than the STANDARD version.

In the STANDARD version the condenser is replaced with a plate heat exchanger, that becomes the main component responsible for the heat extraction in the cooling unit. The plate heat exchanger is also connected to the FLOW waterloop system, where with the use of a designated piping system, the heat can be trasfered to a desired location.

In the HYBRID version the plate heat exchanger is added to the cooling instalation without removing the condenser. In this version two components, the exchander and condenser, are both respondible for exctracting the heat from the appliance. Firstly the heat plate exchanger gathers the heat to the waterloop system. The residual heat travels to the condenser and is extracted to the ambient air. This provides more flexibility and safety than the STANDARD version.

In every case the FLOWsystem is individually tailored to the customers’ requirements and the store’s design. The choise of a suitable Dry Cooler package and piping system diameters, adapting the air conditioning system and a proper calibration by a specialist are necessary for the FLOWsystem to work efficiently.

For each set of appliences to be connected to the FLOWsystem, the Dry Cooller package is individually chosen depending on the total cooling power of all of the appliances to be located in the store.

In every case the FLOWsystem is individually tailored to the customers’ requirements and the store’s design. The choise of a suitable Dry Cooler package and piping system diameters, adapting the air conditioning system and a proper calibration by a specialist are necessary for the FLOWsystem to work efficiently.

For each set of appliences to be connected to the FLOWsystem, the Dry Cooller package is individually chosen depending on the total cooling power of all of the appliances to be located in the store.

The FLOWsystem can provide you with instant benefits simply by reducing the heat emmission in the store. You can increase the benefits by linking the FLOWsystem with other store installations like air and water heaters or the lighting system.

With a smart management system of every store installation you can arrive at the synergy effect that can give you significant overall savings on the total operating costs.

The FLOWsystem can provide you with instant benefits simply by reducing the heat emmission in the store. You can increase the benefits by linking the FLOWsystem with other store installations like air and water heaters or the lighting system.

With a smart management system of every store installation you can arrive at the synergy effect that can give you significant overall savings on the total operating costs.