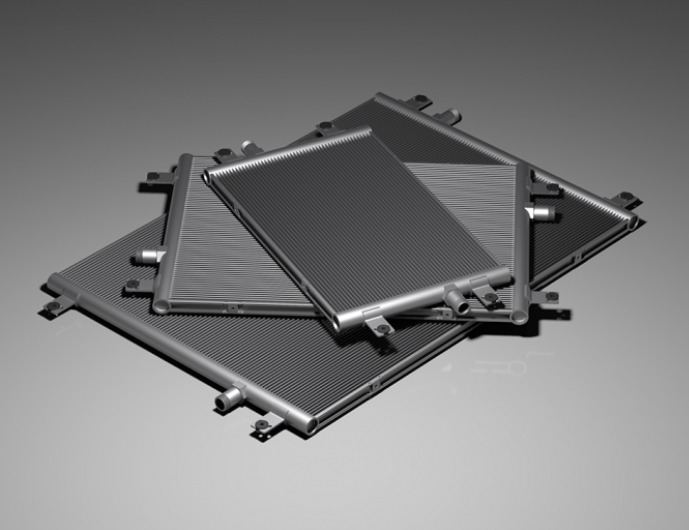

Kaltra advances in creating protective treatments for microchannel heat exchangers and introduces new anti-corrosion coating for dry (fluid) coils to apply to inner surfaces. The new coating enables for an expanded range of process water pH value, a measure of how acidic/basic water is.

The pH range goes from 0 to 14, with 7 being neutral. pHs of less than 7 indicate acidity, whereas a pH of greater than 7 indicates a base. pH is a measure of the relative amount of free hydrogen and hydroxyl ions in the water. The typical pH range for microchannel heat exchangers is 6.0 to 8.5 to prevent corrosion of the aluminum, which may be caused by an oxide layer dissolving at extreme pHs (in both acidic and basic environments).

Controlling the pH within the desired range is critical for controlling aluminum corrosion. Typical water circuits will have a mix of metallurgies like brass, copper, and steel in addition to the aluminum heat exchanger. Corrosion rates for copper and steel would climb if the pH of the system were in the range of 6 to 7. Therefore, it is desirable to maintain the pH near the high end (8.5) to accommodate all the metallurgy of a water system. Another consideration is that di-electric unions can protect aluminum from galvanic corrosion. New chemical treatment of inner surfaces presented by Kaltra allows extending the safe pH range, thus contributing to the corrosion resistance not only of microchannel coils but also the water system as a whole.

Kaltra also recommends a well-proven mechanism of corrosion inhibition of aluminum alloys by sodium molybdate. In a concentration of about 20mM, sodium molybdate (Na2MoO4) demonstrates excellent inhibition efficiency for aluminum alloys used in the manufacturing of microchannel heat exchanger coils. Unlike many other inhibitors, sodium molybdate also doesn’t contribute nutrients, which can exacerbate microbiological activity in closed-circuit water systems.

As of now, all Kaltra water coils supplied treated with a new inner coating, offering customers the benefits of extended coil service life in a wide range of environments and process water qualities.