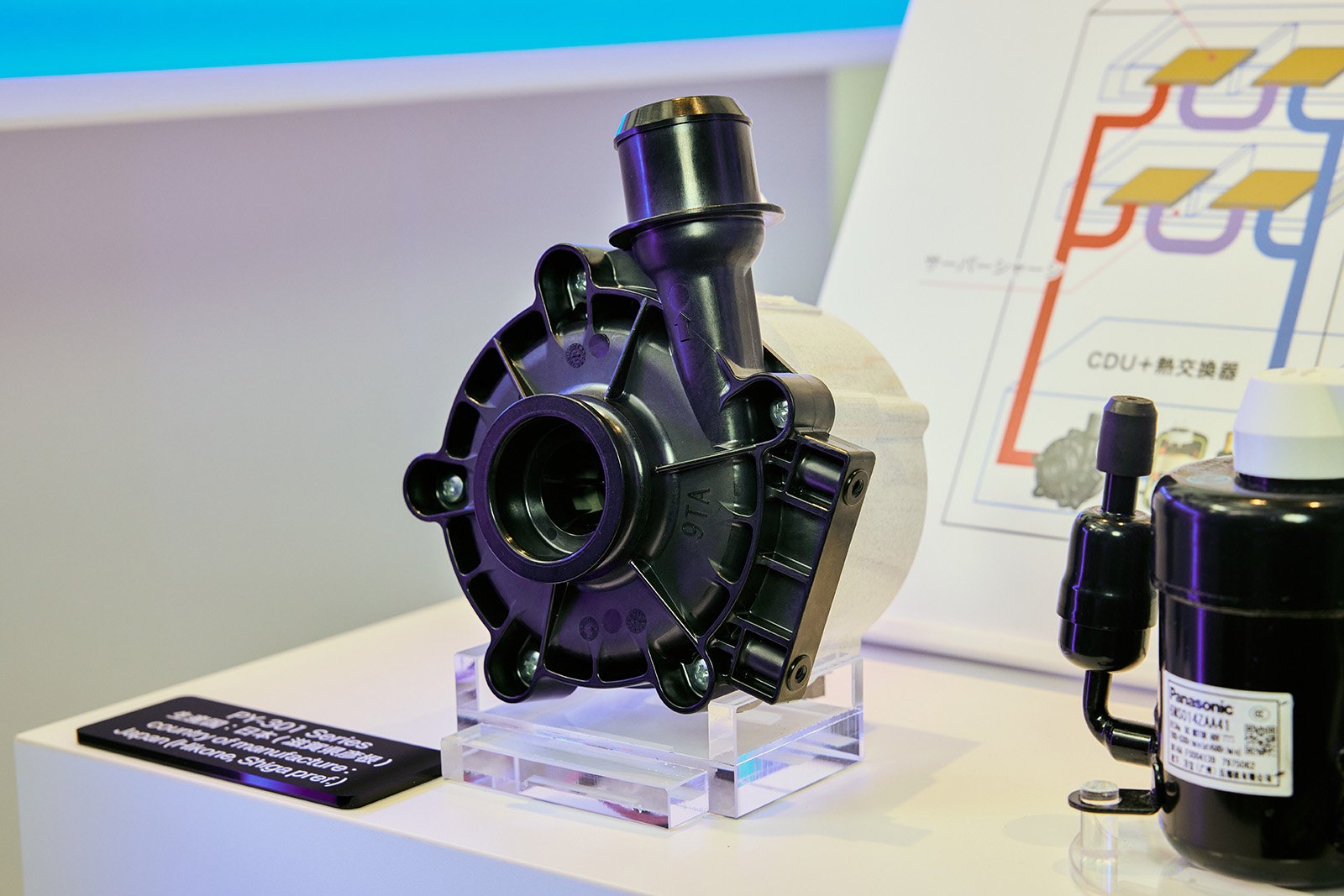

Panasonic has introduced a new liquid cooling pump designed for server cooling in AI and data center infrastructure, leveraging 70 years of expertise in pump technology. The pump is a core component of a Coolant Distribution Unit (CDU), which helps efficiently circulate coolant to manage the heat generated by advanced chips in AI servers.

Liquid cooling is gaining traction as a preferred method over traditional air-based systems, especially for high-performance GPUs and AI accelerators. Panasonic’s CDU integrates three compact pump units within a 4U (178 mm) server rack space—two operate continuously while one serves as a backup, ensuring system reliability and cooling redundancy.

The new pump offers a 75% increase in flow rate—from 40 to 70 liters per minute—without increasing its physical size. Panasonic achieved this by applying proprietary encapsulation technology, advanced magnetic and fluid analysis, and an integrated motor-pump structure. The pump uses a self-lubricating, submerged sliding bearing to reduce wear and extend service life.

Panasonic began entering the data center market in 2021, initially focusing on Taiwan. The company works closely with its local sales company and Panasonic group entities to meet evolving customer needs and to adapt to specification changes during production. The pump has been well received by AI server ODMs and data center firms in the region.

All design, development, and manufacturing for the pump are handled at Panasonic’s Hikone Plant in Japan, which uses an integrated production system to ensure high precision and fast responsiveness. The facility is scheduled to expand with a new wing by the end of March 2028 to meet rising global demand.

“Advancements in cooling technology directly impact not only the progress of an AI-assisted society but also the future of our planet’s environment,” said Koji Nakamura, Director of the Device Products Business Unit. “Our immediate goal is to achieve cumulative shipments of 100 million units by 2035.”