Toshiba Air Conditioning UK has launched a new generation of its pioneering refrigerant detection and management system, which further reduces costs, saves space and is even more flexible in application.The new LD2 provides protection for building occupants in the unlikely event of a refrigerant leak, and buildson the success of the company’s award-winning RD6, which has been redesigned and re-engineered.

Schematic showing the configuration of the LD2 system

Schematic showing the configuration of the LD2 system

David Dunn, managing director of Toshiba Air Conditioning and CIAT in the UK, said, “This latest generation of Toshiba’s refrigerant detection and management system gives end users and building occupants peace of mind, delivering the same high level of protection and functionality as its predecessor for significantly less cost.”

The unit is 40 percent smaller than its predecessor, as it now handles all of the information processing and analysis previously carried out by the dedicated board within the RD6 panel. This new approach enables LD2 to provide all the functions of RD6with reducedinstallation time. The space-saving offers an advantage on sites with restricted plant room space and/or limited access.

Onsite installation time is reduced as wiring from refrigerant leak sensors does not need to be connected to the remote panel. In addition, the detector can now be installed farther away from the unit, expanding on the distance limit of 12m on the RD6.

Toshiba’s ground-breaking leak detection technology was originally designed in the UK to meet the local requirements of end users. However, the new generation LD2 is now available across Europe on Toshiba’s SMMS-e and SHRM-e VRF air conditioning systems.

In line with Toshiba’s focus on meeting specific customer needs in key regions, a UK version of LD2 incorporates additional features such as a low ambient protection heater, remote indication relay and hinged Perspex protection cover over switches and indicators.

“For contractors, LD2 is quick and easy to install onsite, taking up less space and requiring less wiring to implement,” Dunn said. “With the UK-specific version, end users and installers have a system that precisely meets their requirements, and for less investment than the forerunner. In terms of innovation, cost and ease of application, we believe LD2 is a major step forward, and will open up Toshiba’s high level and secure approach to refrigerant management to all VRF-based air conditioning applications across the country.”

The company’s range of refrigerant leak detection, concentration sensors and pump back systems provide a solution to potential leak issues by sounding an alarm in accordance with EN378 - where the refrigerant concentration level exceeds 0.44kg/m3 - and automatically initiating mechanical isolation and pump back of refrigerant from the indoor side to the outdoor unit(s).

The system has the ability to isolate the specific section of refrigerant pipework containing the leak, enabling the rest of the system to continue functioning as normal when combined with Toshiba’s LD1.The new technology means that only the immediate area served by the compromised circuit suffers loss of service.

This latest LD2 system can incorporate both external and internal sensors to monitor and determine the level of refrigerant in the enclosed atmosphere and flowing within the refrigerant piping system.

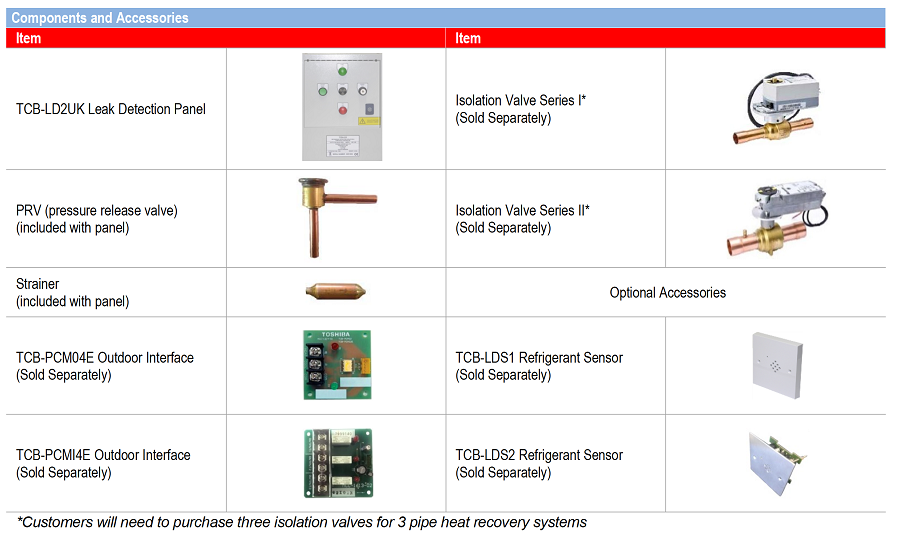

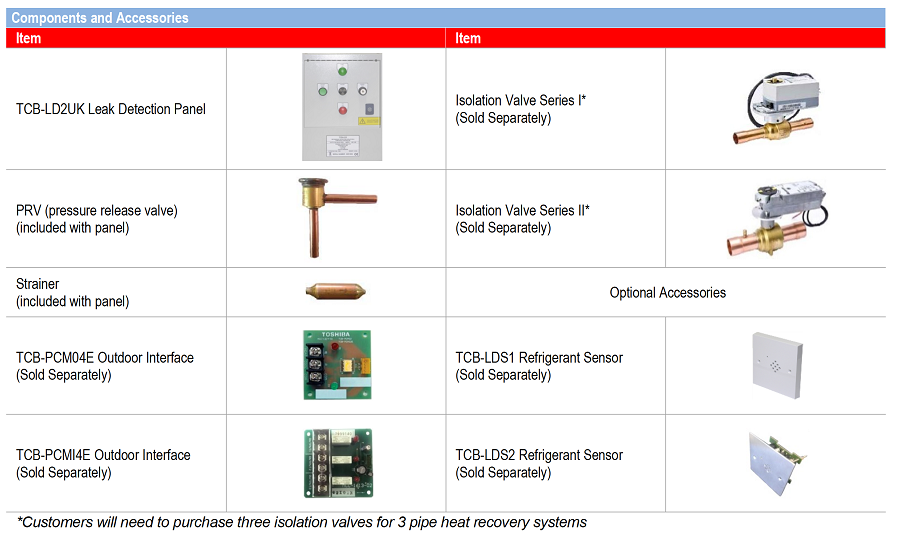

The components and accessories that make up the Toshiba LD2 system

The components and accessories that make up the Toshiba LD2 system

Schematic showing the configuration of the LD2 system

David Dunn, managing director of Toshiba Air Conditioning and CIAT in the UK, said, “This latest generation of Toshiba’s refrigerant detection and management system gives end users and building occupants peace of mind, delivering the same high level of protection and functionality as its predecessor for significantly less cost.”

The unit is 40 percent smaller than its predecessor, as it now handles all of the information processing and analysis previously carried out by the dedicated board within the RD6 panel. This new approach enables LD2 to provide all the functions of RD6with reducedinstallation time. The space-saving offers an advantage on sites with restricted plant room space and/or limited access.

Onsite installation time is reduced as wiring from refrigerant leak sensors does not need to be connected to the remote panel. In addition, the detector can now be installed farther away from the unit, expanding on the distance limit of 12m on the RD6.

Toshiba’s ground-breaking leak detection technology was originally designed in the UK to meet the local requirements of end users. However, the new generation LD2 is now available across Europe on Toshiba’s SMMS-e and SHRM-e VRF air conditioning systems.

In line with Toshiba’s focus on meeting specific customer needs in key regions, a UK version of LD2 incorporates additional features such as a low ambient protection heater, remote indication relay and hinged Perspex protection cover over switches and indicators.

“For contractors, LD2 is quick and easy to install onsite, taking up less space and requiring less wiring to implement,” Dunn said. “With the UK-specific version, end users and installers have a system that precisely meets their requirements, and for less investment than the forerunner. In terms of innovation, cost and ease of application, we believe LD2 is a major step forward, and will open up Toshiba’s high level and secure approach to refrigerant management to all VRF-based air conditioning applications across the country.”

The company’s range of refrigerant leak detection, concentration sensors and pump back systems provide a solution to potential leak issues by sounding an alarm in accordance with EN378 - where the refrigerant concentration level exceeds 0.44kg/m3 - and automatically initiating mechanical isolation and pump back of refrigerant from the indoor side to the outdoor unit(s).

The system has the ability to isolate the specific section of refrigerant pipework containing the leak, enabling the rest of the system to continue functioning as normal when combined with Toshiba’s LD1.The new technology means that only the immediate area served by the compromised circuit suffers loss of service.

This latest LD2 system can incorporate both external and internal sensors to monitor and determine the level of refrigerant in the enclosed atmosphere and flowing within the refrigerant piping system.

Schematic showing the configuration of the LD2 system

David Dunn, managing director of Toshiba Air Conditioning and CIAT in the UK, said, “This latest generation of Toshiba’s refrigerant detection and management system gives end users and building occupants peace of mind, delivering the same high level of protection and functionality as its predecessor for significantly less cost.”

The unit is 40 percent smaller than its predecessor, as it now handles all of the information processing and analysis previously carried out by the dedicated board within the RD6 panel. This new approach enables LD2 to provide all the functions of RD6with reducedinstallation time. The space-saving offers an advantage on sites with restricted plant room space and/or limited access.

Onsite installation time is reduced as wiring from refrigerant leak sensors does not need to be connected to the remote panel. In addition, the detector can now be installed farther away from the unit, expanding on the distance limit of 12m on the RD6.

Toshiba’s ground-breaking leak detection technology was originally designed in the UK to meet the local requirements of end users. However, the new generation LD2 is now available across Europe on Toshiba’s SMMS-e and SHRM-e VRF air conditioning systems.

In line with Toshiba’s focus on meeting specific customer needs in key regions, a UK version of LD2 incorporates additional features such as a low ambient protection heater, remote indication relay and hinged Perspex protection cover over switches and indicators.

“For contractors, LD2 is quick and easy to install onsite, taking up less space and requiring less wiring to implement,” Dunn said. “With the UK-specific version, end users and installers have a system that precisely meets their requirements, and for less investment than the forerunner. In terms of innovation, cost and ease of application, we believe LD2 is a major step forward, and will open up Toshiba’s high level and secure approach to refrigerant management to all VRF-based air conditioning applications across the country.”

The company’s range of refrigerant leak detection, concentration sensors and pump back systems provide a solution to potential leak issues by sounding an alarm in accordance with EN378 - where the refrigerant concentration level exceeds 0.44kg/m3 - and automatically initiating mechanical isolation and pump back of refrigerant from the indoor side to the outdoor unit(s).

The system has the ability to isolate the specific section of refrigerant pipework containing the leak, enabling the rest of the system to continue functioning as normal when combined with Toshiba’s LD1.The new technology means that only the immediate area served by the compromised circuit suffers loss of service.

This latest LD2 system can incorporate both external and internal sensors to monitor and determine the level of refrigerant in the enclosed atmosphere and flowing within the refrigerant piping system.

The components and accessories that make up the Toshiba LD2 system

The components and accessories that make up the Toshiba LD2 system