BAC Unveiled Groundbreaking Cooling Solutions at Chillventa 2024

At Chillventa 2024, Baltimore Aircoil (BAC) showcased its latest innovations, reflecting its commitment to sustainability, energy efficiency, and technological advancement. These products were designed to meet the cooling demands of critical environments like data centers and industrial facilities, while also addressing environmental challenges.

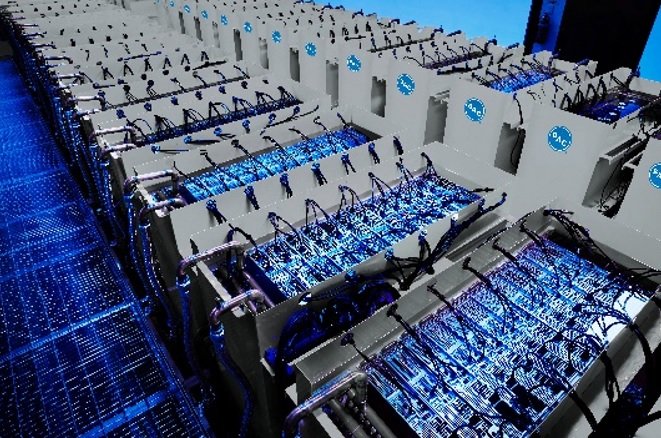

Energy-Efficient Immersion Cooling for Data Centers

BAC introduced its revolutionary immersion cooling solution, which cuts cooling energy consumption by up to 95%. This innovation extended the lifespan of servers and drastically reduced maintenance needs, offering a scalable and environmentally responsible solution for the data center industry. The immersion cooling system proved to be an efficient option for organizations looking to minimize operational costs while staying future-ready.

High-Capacity Dry Cooling Solutions for Maximum Efficiency

At Chillventa, BAC presented its TrilliumSeries Dry Cooler (TDFS), a product designed to provide best-in-class heat rejection with minimal energy usage. The vertical coil design and multiple coil circuiting allowed for reduced pumping energy costs, while the redundant fan system ensured uninterrupted operation, even during signal loss. The low sound profile and easy maintenance access made this cooler an ideal solution for operations requiring quiet, low-maintenance, and high-efficiency cooling.

3rd Generation Polairis Evaporative Condenser: Unmatched Capacity and Reliability

BAC introduced the 3rd generation Polairis evaporative condenser (PLC3), which set new standards in the industry. This product offered the highest capacity in its class, with ultra-quiet operation, unparalleled reliability, and superior hygiene standards. Equipped with high-efficiency radial fans and the DiamondClear® Design, it ensured long-term, trouble-free performance with minimal maintenance, making it a top choice for a wide range of applications.

5th Generation TrilliumSeries: Sustainable Adiabatic Cooling

BAC also unveiled the 5th generation TrilliumSeries products, offering a sustainable and cost-efficient approach to adiabatic cooling systems. These innovations, supported by full-scale testing, maximized thermal capacity and provided significant annual cost savings. The company emphasized the rapid return on investment of under 1.5 years and highlighted the enhanced production capacity through in-house manufacturing of key components, ensuring consistent quality and scalability to meet market demands.

MATRXDRIVE: Revolutionary Fan Array System

The MATRXDRIVE system, a new product introduced by BAC, featured an advanced direct-drive design with permanent magnet motors and variable frequency drives (VFDs) for superior energy efficiency and performance control. Specifically designed for BAC’s FXVS evaporative closed-circuit coolers and CXVS evaporative condensers, the MATRXDRIVE system delivered maximum performance with minimal maintenance, ensuring long-term reliability and reduced operational costs.

Smart Factories: Driving Innovation in Sustainable Manufacturing

BAC also showcased its smart factories in Belgium and Italy, which were key to the company’s sustainable manufacturing efforts. These state-of-the-art facilities utilized advanced technologies to minimize environmental impact while ensuring efficient production. Live demonstrations at Chillventa highlighted how BAC’s manufacturing processes integrated intelligent systems to meet global demand sustainably and efficiently.