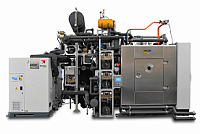

Freeze Drying solution for pharma industry

Where:

Germany

Contractor:

MIRAI Intex s.r.o.

Description

The F-Gas regulation brings upcoming changes in the near future more ecological and more economical solutions to need to be implemented. Many recent refrigerants have zero ODP (Ozone Depletion Potential) but are still burdened with high GWP (Global Warming Potential). Air does not only have 0 ODP and 0 GWP but is also totally free of charge and absolutely safe to operate.

Due to the strategic outlook, HOF Sonderanlagenbau GmbH asked MIRAI Intex to supply their novel natural refrigeration units for their lyophilization system. The assignment was to retrofit the existing unit’s refrigeration system. Proving that not only new state-of-the-art freeze dryers can be paired with Mirai Intex products but also existing equipment could be refurbished and upgraded to make it “future-proof”. Our partner Refolution GmbH has been providing active engineering support throughout this project.

Two MIRAI Cold 10 C/W/T units have been selected to provide the necessary cooling power. This is a closed cycle machine equipped with an additional heat exchanger working with primary and secondary loop. The primary loop is the machine’s internal circuit operating with air. The heat transfer is taking place in the heat exchanger intersecting with the secondary loop which operates with heat transfer fluid. For freeze-drying applications, this secondary medium is usually silicone oil which was used in this application as well. MIRAI Cold refrigeration machines are providing oil cooled down to temperatures from -70°C down to -100°C in this particular application. The oil reservoir was used to cover the peak load required for cooled oil in this process.

As of today, this retrofitted system has been severely tested and clocked over 5.000 hours of operations and still counting. Preliminary results show up to 15% energy efficiency increase compared to the sister unit which is the identical unit running with the conventional compressor refrigeration system using HFC refrigerants.

Read more

Due to the strategic outlook, HOF Sonderanlagenbau GmbH asked MIRAI Intex to supply their novel natural refrigeration units for their lyophilization system. The assignment was to retrofit the existing unit’s refrigeration system. Proving that not only new state-of-the-art freeze dryers can be paired with Mirai Intex products but also existing equipment could be refurbished and upgraded to make it “future-proof”. Our partner Refolution GmbH has been providing active engineering support throughout this project.

Two MIRAI Cold 10 C/W/T units have been selected to provide the necessary cooling power. This is a closed cycle machine equipped with an additional heat exchanger working with primary and secondary loop. The primary loop is the machine’s internal circuit operating with air. The heat transfer is taking place in the heat exchanger intersecting with the secondary loop which operates with heat transfer fluid. For freeze-drying applications, this secondary medium is usually silicone oil which was used in this application as well. MIRAI Cold refrigeration machines are providing oil cooled down to temperatures from -70°C down to -100°C in this particular application. The oil reservoir was used to cover the peak load required for cooled oil in this process.

As of today, this retrofitted system has been severely tested and clocked over 5.000 hours of operations and still counting. Preliminary results show up to 15% energy efficiency increase compared to the sister unit which is the identical unit running with the conventional compressor refrigeration system using HFC refrigerants.