BAC (Baltimore Aircoil Company Inc.) has announced that its immersion cooling tank is now certified under the Intel Data Center Certified Solution for Immersion Cooling program, covering fourth and fifth-generation Xeon processors. This certification highlights progress in validating next-generation immersion cooling solutions aligned with the performance and sustainability demands of modern data centers.

The certification follows a rigorous testing process involving immersion cooling tanks, fluids, and IT hardware. The program was jointly developed by BAC, Intel, ExxonMobil, Hypertec, and Micron, reflecting cross-industry collaboration in advancing cooling technologies. It also allows Intel to offer a Xeon Processor Single-Phase Immersion Warranty Rider, supporting customer confidence in immersion-cooled infrastructure.

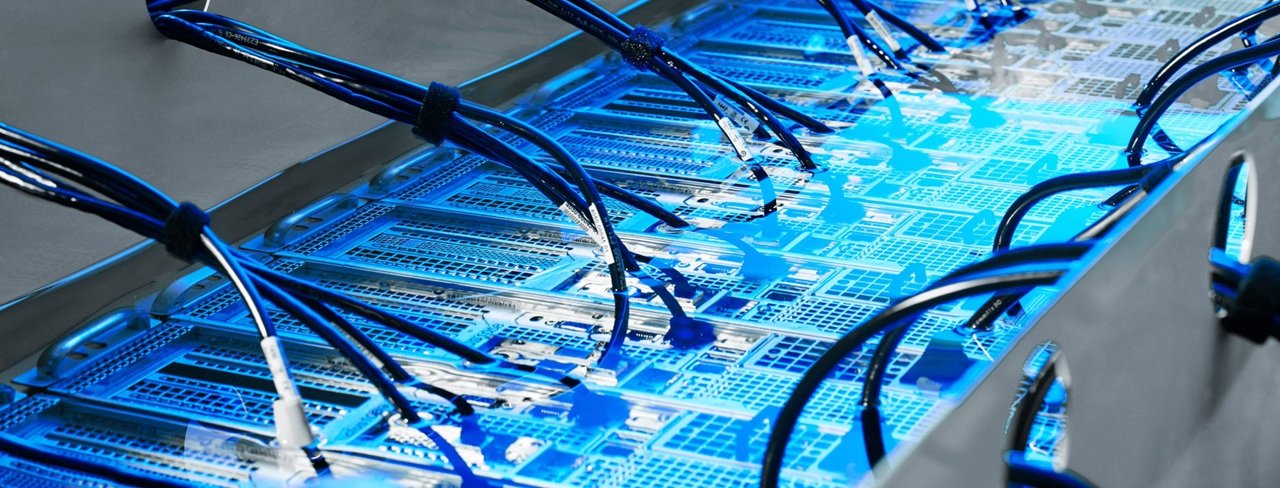

Testing took place at Intel’s Advanced Data Center Development Lab in Hillsboro, Oregon. BAC’s immersion cooling tanks, featuring patented CorTex technology, were used to evaluate tank performance, reliability, and the interaction between cooling fluids and IT hardware.

“Immersion cooling represents a critical advancement in data center thermal management, and this certification is a powerful validation of that progress,” said Jan Tysebaert, BAC’s General Manager of Data Centers.

The Intel certification supports BAC’s broader portfolio, including the COBALT immersion cooling system, which integrates an indoor immersion tank with an outdoor heat rejection unit. The system is designed to help data centers reduce Power Usage Effectiveness (PUE) while supporting uptime and sustainability goals.

“Certification programs like this one are key to accelerating industry adoption by ensuring every element — tank, fluid, processor, and memory — meets the same high standards of reliability and performance,” added Tysebaert.