Daikin Industries, Ltd. (Japan), UACJ Corporation (Japan), and Nihon Jiryoku Senkou Co., Ltd. (Japan) have jointly demonstrated a horizontal recycling technology for aluminum fins used in HVAC heat exchangers. This marks the first successful industry trial of aluminum fin regeneration from used heat exchangers as of September 2025, according to Daikin.

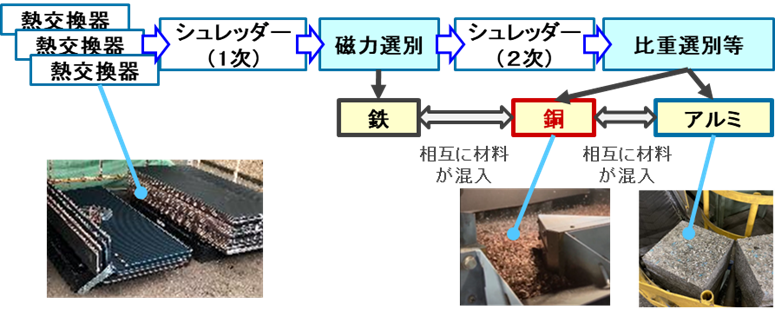

Typically, high-purity aluminum is used in HVAC heat exchangers for its workability. However, aluminum recovered from used units contains copper and other impurities, making it suitable only for downgraded applications such as automotive engine parts. Horizontal recycling—reusing the material in the same-grade application—had not been feasible due to contamination and processing challenges.

In the joint project, Nihon Jiryoku developed a high-precision separation technology that reduced copper content in the recovered aluminum from around 3% to less than 0.1%. UACJ addressed formability issues by developing aluminum material with improved press workability, even when minor impurities remain. Daikin then successfully used this recycled aluminum to press fins and manufacture heat exchangers on its production line.

Recycling aluminum emits up to 97% less CO2 compared to primary aluminum production. The demonstrated closed-loop process is expected to significantly reduce lifecycle emissions from heat exchanger aluminum fins.

Daikin plans to begin mass production using recovered aluminum from used heat exchangers collected at its factories and service operations. The company will gradually expand the initiative to include commercial HVAC units and other components not covered by Japan’s Home Appliance Recycling Law.