gold partner

19 July 2023

Frascold and Aircodue Innovate Railway Air Conditioning Systems with a CO2 Heat Pump

Frascold and Aircodue promote sustainable progress

The teamwork between Frascold and the start-up Aircodue – a spin-off of the Miri Group developed an innovative CO2 heat pump, which features several technological innovations and is equipped with compressors from Frascold’s transcritical series. Four ambitious goals underpin the partnership – energy savings, low environmental impact, low maintenance costs and enhanced reliability, in full compliance with national and international standards.ARCA project makes air conditioning natural

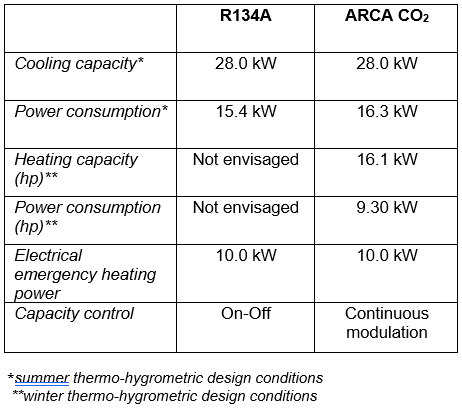

ARCA project – Air Source Reversible CO2 Air Conditioner – by Aircodue, adopts patented technical solutions and takes the form of a demonstrator of a split system of approximately 28 kW, calibrated to the demands of a medium-distance railway carriage, which is used extensively in Italy. In co-operation with Frascold, the research project investigated whether it would be possible to replace an existing (drop-in) system with a new CO2 heat pump, capable of operating in line with the previous configuration and supplying entire multiple unit requirements. As a sine qua non, the new solution cannot draw or require more power than the original R134A system, where a static converter transforms direct current into alternating current and supplies all on-board consumers.The heat pump consists of an outdoor unit, containing primary and auxiliary circuit compressors, and an indoor unit, the ventilating section responsible for cooling and heating the passenger space.

In order to select the most suitable compressor for application purposes, the two technical teams used Frascold’s software to evaluate its performance across the entire operating range and then opted for the TK piston series in the D-TK model, featuring transcritical technology. A byword for outstanding efficiency, flexibility and reliability, these compressors are designed to cope with high standstill pressures, owing to their robust design and a standstill pressure of up to 100 bar (a), thereby guaranteeing superior safety standards. A distinctive feature in this family is CapaFlex mechanical regulation, which allows the modulation of refrigerant flow through the suction inlets. The alternating opening and closing intervals ensure correct partialisation of the compressor, resulting in an optimal load that minimises on-off cycles. A control system providing a considerable benefit, even in terms of performance. An additional plus point of the D-TKs is low oil carry-over, which minimises leakage and provides protection and lubrication for all moving parts.

The Air Source Reversible CO2 Air Conditioner figures speak for themselves

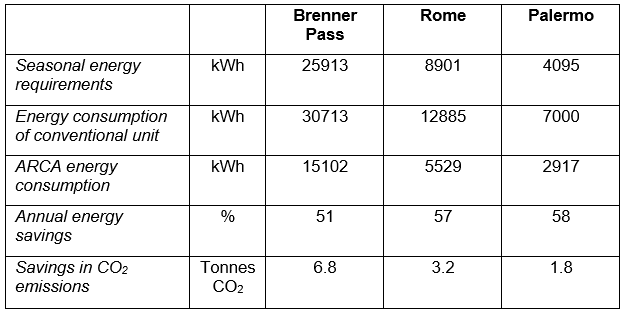

The performance data of the heat pump were compared with those of a conventional system by dynamically simulating operation in heating mode over a wide range of winter temperatures. Conducted through the Energy Diagnostics of a medium-distance vehicle and using dedicated software, the analysis took three locations representative of Italy's main geographical areas, namely the Brenner Pass, Rome and Palermo.

Once the prototype was built, a large-scale climate chamber testing programme was carried out, during which the performance in terms of both heating and cooling was verified, thereby confirming the theoretical data.

Mirco Pasotti, Frascold Sales Area Manager, says, “The results of the analysis are remarkable. The heat pump delivers savings ranging from 51% to 58% depending on zone, with a considerable reduction in terms of tonnes of CO2 emissions into the atmosphere.” Luigi Buttiglione, Aircodue Technical Manager, goes on, “A major design project for the railway industry, where the choice of a natural refrigerant requires careful evaluation in terms of installation and regulatory framework.” Giovanni Paone, Aircodue Chairman, ends – “In addition to being a viable solution to the phase-out policies for fluorinated refrigerants, CO2 complies with the environmental and safety policies of the leading players in the industry. In this respect, Frascold played a key role by virtue of its expertise in the field. A long-standing partner, with whom we have been working to develop next-generation technologies for a responsible evolution in the sector.”

Related news

IEA: Global demand for cooling surges, spotlight on efficiency and ...

The International Energy Agency (IEA) highlights the urgent need for energy-efficient and equitable cooling solutions, as global temperatures and incomes rise. In 2024, average global temperatures ...

today

University of Ljubljana Develops Solid-State Cooling to Replace Tox...

New elastocaloric system promises safer, more efficient alternative to vapor-compression cooling.

Researchers at the University of Ljubljana, Slovenia, are developing a solid-state c

14 May 2025

AREA and WRD announce finalists for 2025 Women in Cooling Video Com...

AREA and World Refrigeration Day (WRD) have announced the finalists for the third edition of the Women in Cooling Video Competition. The initiative highlights the expertise of women in the refr...

23 May 2025

BSRIA gains UKAS accreditation for heat pump testing

BSRIA has extended its UKAS-accredited testing capabilities to include the EN 14825:2022 standard, following a successful ISO 17025 audit by the UK’s National Accreditation Service. This developmen...

28 Jul 2025

Eberspaecher expands bus HVAC range with natural refrigerants and d...

Eberspaecher has introduced new thermal management systems for buses, focusing on energy efficiency, natural refrigerants, and cloud-based services. The portfolio includes the AC138 EVO and the exp...

28 Jul 2025

UK industry group urges government to fund home cooling grants

The UK’s Building Engineering Services Association (BESA) has called for government-backed summer cooling schemes to protect vulnerable populations during increasingly severe heatwaves.

BESA, ...

31 Jul 2025