Researchers at the Hong Kong University of Science and Technology (HKUST) have developed the world’s first sub-zero Celsius elastocaloric freezing device, capable of reaching -12°C. The breakthrough expands solid-state elastocaloric cooling into freezing applications, offering a potential zero-emission alternative to conventional vapor compression systems that rely on high-GWP refrigerants. The results were published in Nature under the title “Sub-zero Celsius Elastocaloric Cooling via Low-transition-temperature Alloys”.

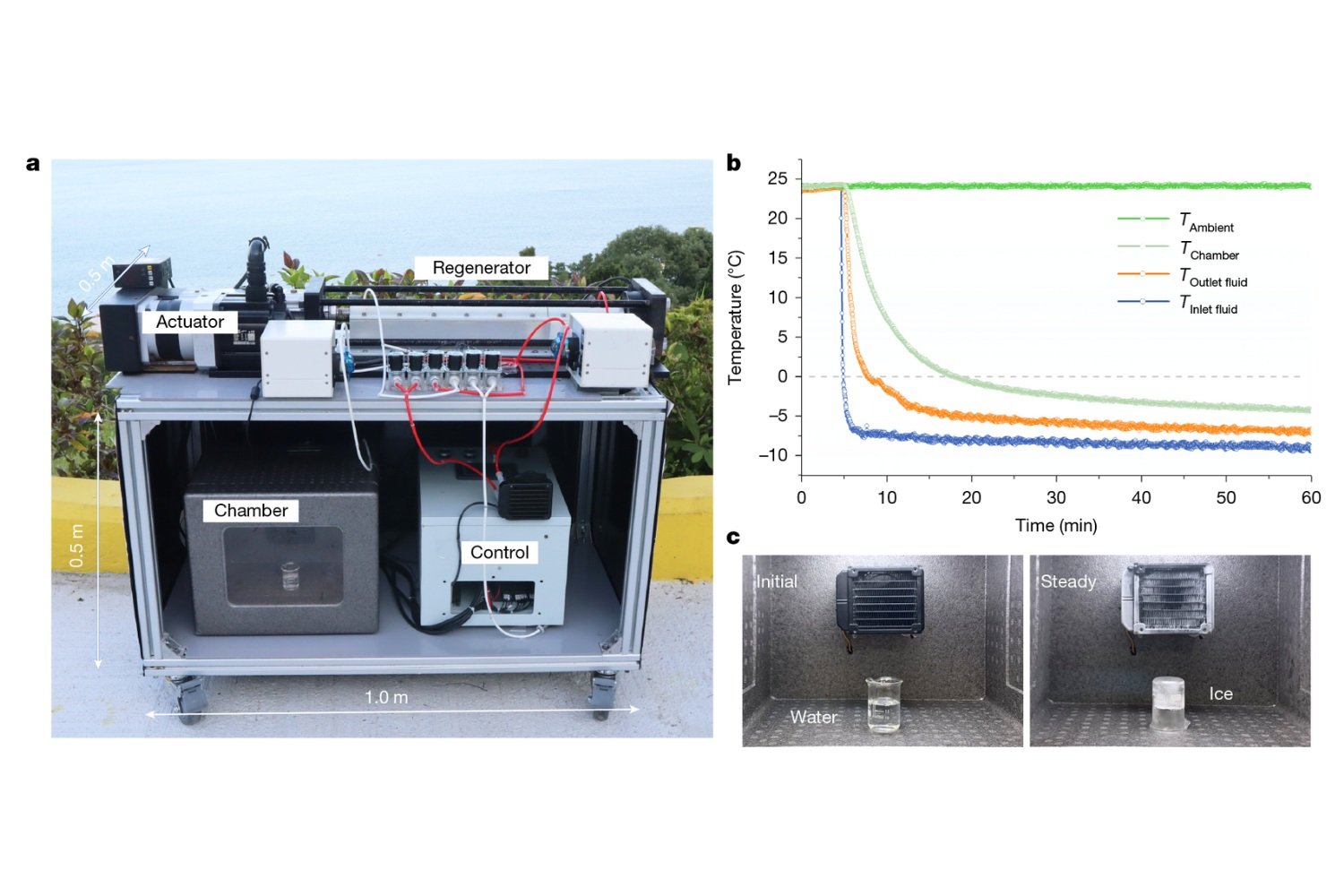

The device was developed by a team from HKUST’s Department of Mechanical and Aerospace Engineering, led by Prof. Sun Qingping. Operating at 1 Hz, the system reached a cold-source temperature of -12°C from a room-temperature heat sink at 24°C, achieving a 36°C temperature lift. The research demonstrates the first reported sub-zero performance in elastocaloric cooling.

The system integrates three main features: a binary nickel-titanium (NiTi) alloy with a low austenite finish temperature of -20.8°C; a 30 wt% aqueous calcium chloride solution as freezing-resistant heat transfer fluid; and a cascaded tubular architecture consisting of eight regenerator units using thin-walled NiTi tubes. The structure operates on a compression-based active Brayton cycle and withstands compressive stress up to 900 MPa.

In real-world testing, the device cooled an insulated chamber to -4°C within 60 minutes and froze 20 ml of distilled water in 2 hours. It demonstrated a specific cooling power of up to 1.43 W g⁻¹ under zero-temperature-lift conditions, and a potential coefficient of performance of 3.4 under ideal work-recovery assumptions.

The team noted that sub-zero freezing accounts for about 27% of projected global HFC emissions, estimated at 330 million tons CO₂-equivalent per year by 2025. The emission-free elastocaloric alternative could contribute to mitigating this impact.

Prof. Sun Qingping stated, “This achievement demonstrates the potential for large-scale application of elastocaloric freezing technology. We are collaborating with industry to drive its commercialization.” He added that ongoing research will focus on improving system efficiency, power density, and cost-effectiveness.

Prof. Lu Mengqian, Director of the HKUST Otto Poon Center for Climate Resilience and Sustainability, called the work “a significant step forward in our fight against climate change”, and noted that it aligns with the center’s mission to deliver sustainable development strategies.

The research was supported by the Hong Kong Research Grants Council, Innovation and Technology Commission, and Shenzhen-Hong Kong collaborative initiatives. This marks the team’s second publication in Nature within a year.