When investing in new technologies it might be difficult to know whether it is worth it or not. However, with the new calculation tool from Advansor it is now possible to calculate the pay-back time and energy savings.

Advansor has developed a calculation tool that estimates the energy savings and pay-back time for any additional investment to a refrigeration rack based on the specific rack, the technology and the surrounding climate.

Kenneth Bank Madsen, Technical Director at Advansor explains: “it is always exiting to develop a lot of functions and features, but if it does not provide higher efficiency or reduce energy consumption, we do not recommend it to our customers – we want to make sure they get value for money, not just investing in new technologies”.

The new technological add-ons are many and will only increase in the future. For beginners Advansor recommends at least investing in permanent magnet motors. This is usually always a highly efficient solution that reduces the pay-back time for refrigeration racks above 30 kW.

New Cylinder Unloading Technology for better capacity regulation

Depending on the compressors and the rack, it might also be worth adding the new cylinder unloading technology to a rack specification. By using the new cylinder unloading technology a better capacity regulation with less compressors are achieved and thereby the energy efficiency is improved. The solution is well-proven and tested offering down to 10% capacity regulation on the lead compressor. This technology can be applied to all racks from 30 kW and up using Bitzer compressors and is widely used by among others the European retail chain COOP.

Ultra-Low Superheat Module for higher energy savings

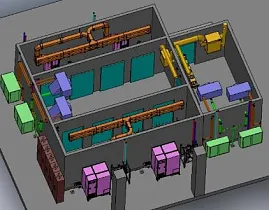

Another new option to add is the Ultra-Low Superheat Module, which can replace the complex pump systems and achieve 95% of the energy savings for 25% of the price. It allows a very low returning temperature from the evaporators and collects any liquid returning. Especially in warm climate this feature has proven very efficient and combined with a gas ejector additional savings up to 20% can be achieved. The ULS Module can be attached to just about any Advansor rack from around 100 kW and up. This module has been installed with refrigeration racks in many different sites from medium sized supermarkets up to big warehouses and for instance for a new logistic centre for TransGourmet in Germany.