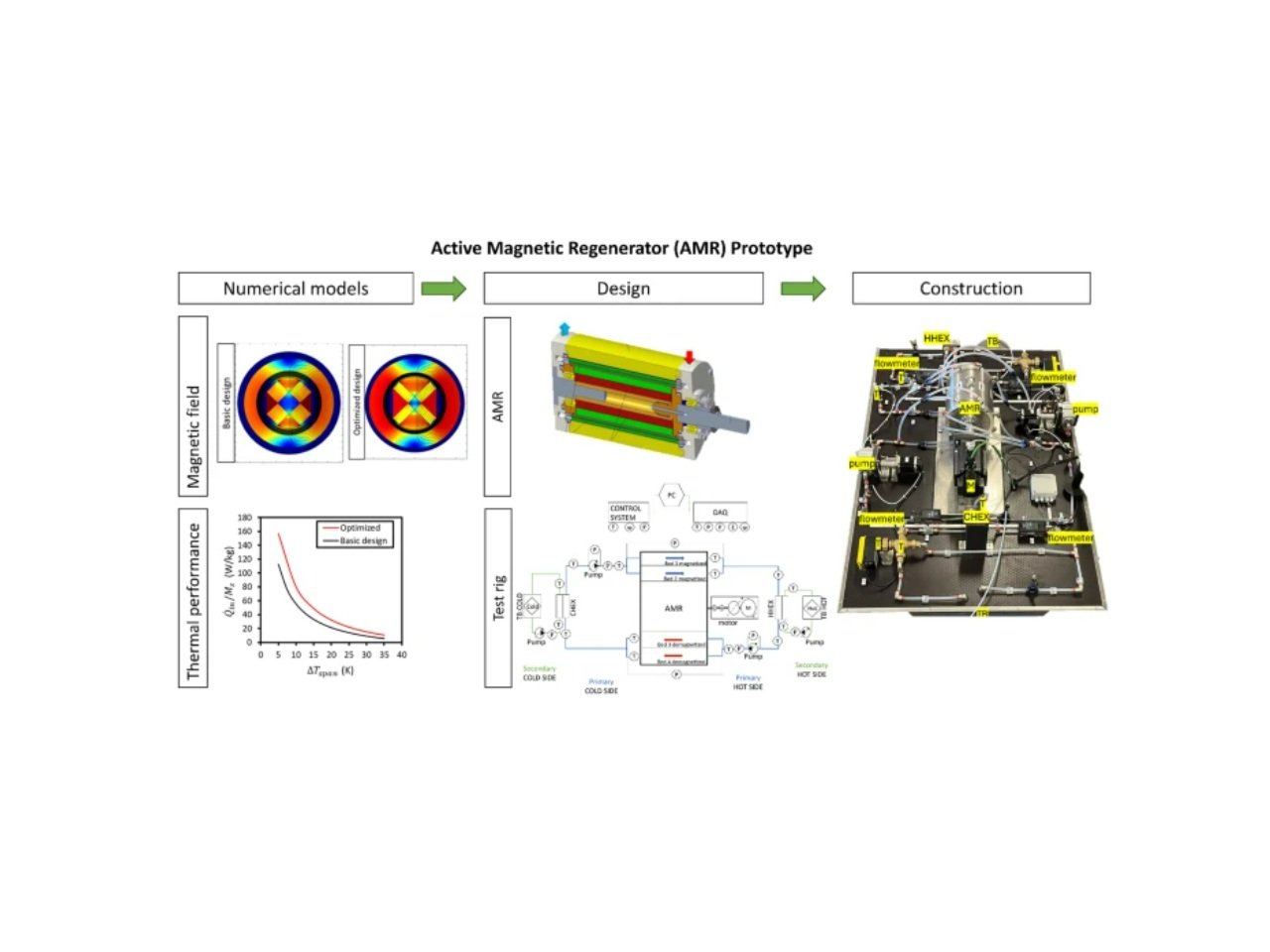

A team of researchers from Italy has developed a new rotary magnetic refrigerator prototype designed for domestic use at room temperature. The project focused on improving efficiency, versatility, and compactness by optimizing key components through numerical simulation methods.

The design process employed an interdisciplinary approach combining mechanical, thermo-hydraulic, and magnet design. The prototype is based on an active magnetic regenerative refrigeration (AMRR) cycle using gadolinium (Gd) as the magnetocaloric material. It integrates a rotating magnetic regenerator with exchangeable 3D-printed cartridges, allowing for easy replacement of the Gd matrix. The structure enables a "double effect" operation—two thermodynamic cycles per revolution—without the need for fluid flow valves.

Optimization of the regenerator, magnet structure, and external heat exchangers was performed using finite element method (FEM) and finite difference simulations. The magnet design uses neodymium-iron-boron (NdFeB) permanent magnets arranged in an X-shape configuration, generating two high-field and two low-field zones. The optimized magnet configuration enhances the magnetic flux while reducing material costs.

Thermo-hydraulic simulations determined optimal operating parameters. For a 15 K temperature span, the device achieves a high cooling load, which drops sharply if the span increases. Simulations suggest a Nusselt number of 8.0 under operational conditions. Control strategies were developed to adjust rotation frequency and mass flowrate depending on the temperature span, maximizing performance while simplifying frequency tuning.

Mechanical design ensures compactness and structural integrity. The rotating active matrix and fixed magnetic assembly allow oscillating flow without valves, enhancing robustness. Gadolinium foils are used in a flat geometry, with a void fraction optimized to 0.35 to reduce friction losses.

Although experimental validation is pending, the prototype has been integrated into a test rig including external heat exchangers and data acquisition systems. This setup will allow real-world performance testing and characterization across various temperature spans.

"The design ensures continuous material usage, minimizing dead volume and maximizing magnet usage," the authors conclude. They highlight the elimination of valves as a feature that simplifies the system and improves reliability. Future work will address experimental validation and investigate alternative magnetocaloric materials and cost-reduction methods.

Source