The first installation of BITZER’s Digital Network (BDN) in Ireland is providing high-level monitoring, system diagnostics and optimisation for an award-winning deli food specialist.

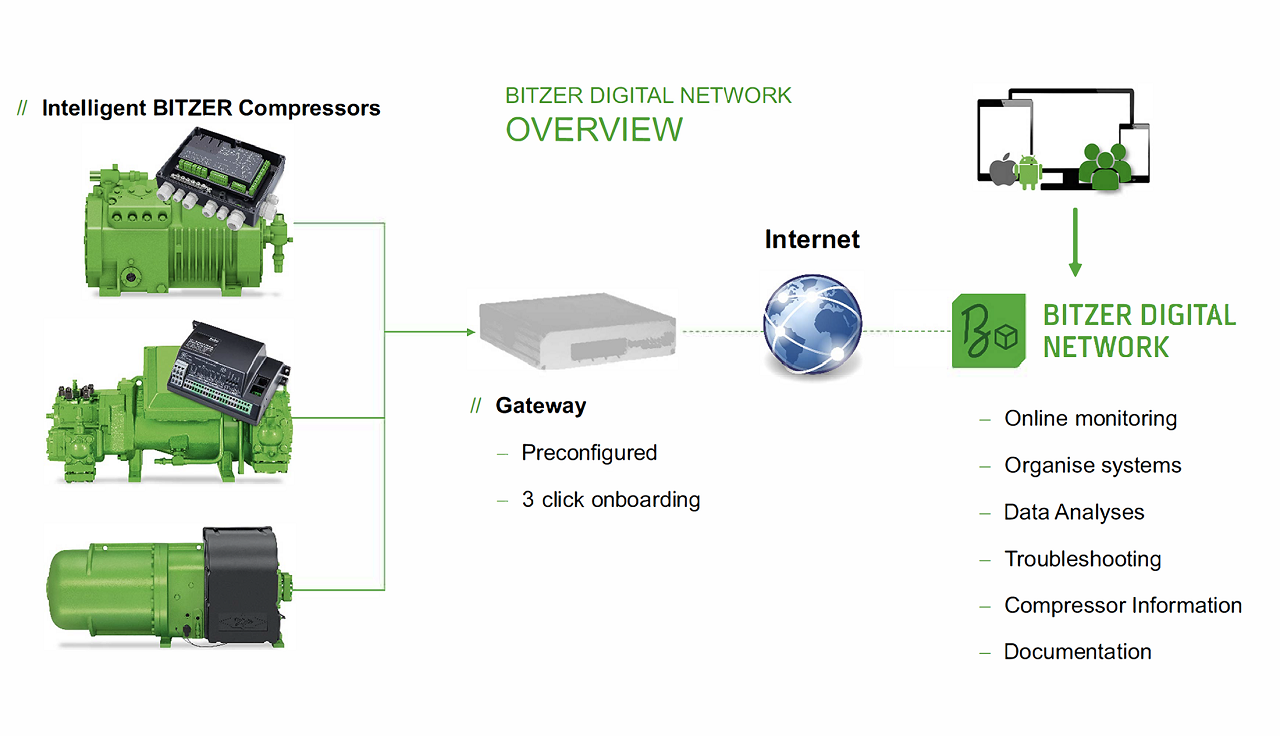

The BDN system is integrated into a new high performance low temperature pack, based on BITZER ECOLINE inverter-controlled compressors supplied by RSL Ireland Ltd.

The new refrigeration system replaced two 30-year-old BITZER condensing units and Searle evaporators operating on R-404A, that had come to the end of their working life.

The new pack was equipped with discharge ball valves, tee-pieces and pipe connections in the factory, enabling it to be connected directly to the site’s existing heat reclaim system, based on three Eureka EX units that produce hot water for process and domestic use.

To ensure continuity of cooling during the replacement project, existing plant was kept running while the new equipment was installed, pressure tested, evacuated and commissioned, ensuring cold room temperatures were maintained until the existing system was switched off and decommissioned.

The compressors are connected to the BDN Gateway via modbus, with BITZER UK providing support to integrate and register the system on the network, enabling all commissioning and real-time performance data to be viewed and recorded, and activating a three-year extended warranty.

The system has built-in capacity for future expansion to cater for growth in the end-user’s business, with an additional space in the pack for a third BITZER ECOLINE compressor.

Paul Lynch, Technical Manager at RSL Ireland Ltd, said: “The client was sold on the idea of a BITZER-based solution because the previous plant had operated so efficiently and trouble-free for 30 years. The additional warranty enabled by connection to BDN also gives peace of mind, knowing from a service perspective what the plant will cost over the next three years.”

He added: “BDN is a great tool and really deserves to be widely adopted. It enables you to drill down and see what is happening – both historically and in real-time – at the level of each compressor.

“Performance can be compared against the operating envelope for each unit, giving valuable insights into what is happening through the operating cycle. This enables you to optimise operation and further improve efficiency. There is no doubt it can save a lot of time and money.”

Kevin Glass, BITZER UK Managing Director, said: “The project is a great example of how useful BDN can be, both to contractors and clients. It opens up almost infinite possibilities for improving refrigeration system performance, reducing running and servicing costs, and minimising the impact of cooling systems on the environment.”

He added: “The need to deliver these improvements has never been greater. The key is timely information about how systems are performing in the real world, and the ability to easily adjust and optimise them. BDN delivers this, and in a user-friendly format that is easy to understand and apply.”

20 February 2024

The first installation of BITZER’s Digital Network (BDN) in Ireland is providing high-level monitoring

Related news

Viessmann Launches System Profi Program to Support Building Electri...

Viessmann has introduced the "System Profi Program" to strengthen collaboration with skilled trades and advance building electrification in Germany. The initiative responds to a market declin...

16 Apr 2025

Carrier adds AI-driven features to Abound Insights Assistant app

Carrier has announced enhancements to its Abound Insights Assistant app, aimed at helping building managers and facilities teams manage equipment operations and streamline maintenance activities. T...

26 Jun 2025

Viessmann Expands Digital Services and Tools for Efficient System M...

Viessmann, part of Carrier Global Corporation, has introduced a range of digital tools and services aimed at supporting its professional partners in the commissioning, monitoring, and planning of h...

30 Jun 2025

Caverion Austria acquires Lepuschitz Kältetechnik GmbH

Caverion Austria has acquired Lepuschitz Kältetechnik GmbH, a refrigeration specialist based in Wernberg, Carinthia. The acquired company employs 18 people and generates annual revenue of approxima...

01 Jul 2025

LFB Group Launches Redge Brand for EMEA HVAC Market

LFB Group, the company behind the Friga-Bohn refrigeration brand, has announced the launch of Redge, a new brand name for its commercial HVAC operations in Europe, the Middle East, and Africa (EMEA...

today

BITZER Mourns Passing of Christiane Schaufler-Münch at 90

Christiane Schaufler-Münch, long-standing figure of the BITZER Group and Chairwoman of THE SCHAUFLER FOUNDATION, has passed away at the age of 90. Her death marks the end of an era for the refriger...

22 Apr 2025