R1234ze is a viable, long-term refrigerant option for a wide range of applications, and enables OEMs and end users to reduce GWP, resulting in direct CO2 emissions and refrigerant cost reductions. What’s more, oil-free systems help meet energy efficiency requirements and increase reliability, with industry-leading part load and excellent full load efficiencies. The oil-free operation additionally guarantees long-term performance at rated levels.

Drew Turner, Global Marketing Manager for Danfoss Cooling Oil-free solutions, stated: “Since we launched our pioneering Turbocor® TG compressor in 2013 and expanded to a full range portfolio in 2017, we’ve been market-leaders in R1234ze and oil-free component qualification testing. While other manufacturers test their components’ performance and reliability using air, Danfoss uses refrigerant in real-world conditions in its Application Development Centers.

“We believe testing in complete systems not only delivers greater accuracy, but also improves reliability and energy efficiency—a win-win situation for our customers and, indeed, their customers too.”

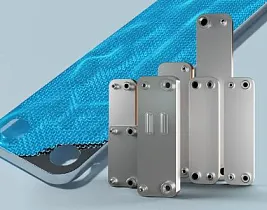

Danfoss’ qualified components are tested to the highest industry standards and designed with the future in mind—with products like ETS Colibri® valves that work with both oiled and oil-free systems. Oil-free compatibility also enables significant sustainability advantages, with hermetically sealed components reducing the chance of leakage.

The clear advantages of using R1234ze in oil-free systems explain why Danfoss expects demand for these qualified components will only increase over time.

Luigi Zamana, Senior Director of Marketing says: “The high standards and rigor to which Danfoss tests components, combined with the sheer size of our component portfolio, means that we can offer leading levels of reliability along with the widest range of capabilities for OEMs.”