Danfoss is expanding its support for industrial decarbonization by developing technologies that enable heat pumps to reach supply temperatures of 120°C (248°F) today, with 150°C (302°F) targeted in the near future.

These advancements address rising demand in high-temperature sectors such as food and beverage, pulp and paper, chemicals, and textiles, where steam and hot water are essential for processes like drying and sterilization. Danfoss also sees a key role for industrial heat pumps in district heating systems, traditionally reliant on fossil fuels.

“To support the development of heat pumps from 100 kW up to 3 MW, we’ve invested heavily in expanding our compressor lineup, compatible with a wide range of refrigerants — from low-GWP HFOs to natural options like CO₂ and hydrocarbons,” said Ivan Rangelov, Industrial Heat Pump Manager at Danfoss Climate Solutions.

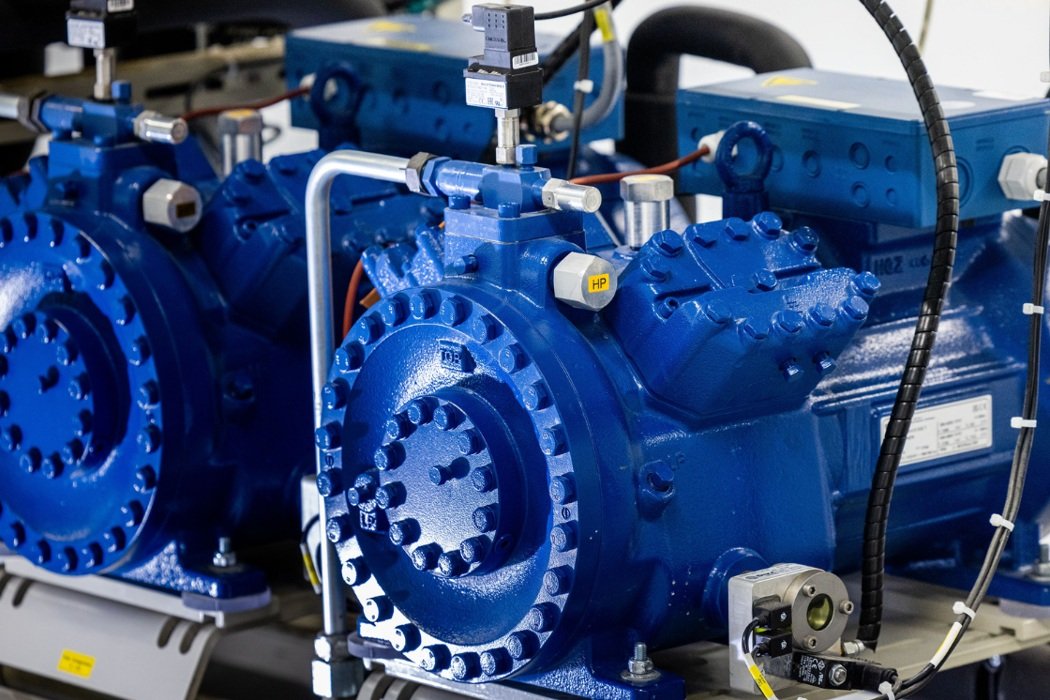

Danfoss provides system design and development support to OEMs, including advanced simulation tools such as the A3S program and testing through its Application Development Centers. Its offering includes a broad compressor portfolio — from scroll and semi-hermetic reciprocating to screw and oil-free centrifugal types — as well as high-temperature components and controls.

The company also offers the Alsmart controller platform, which combines programmable HVAC control hardware with advanced monitoring tools.

“We believe industrial heat pumps will drive the next major wave of decarbonization in industry. This is a fast-growing market, and we’ve made strategic investments to lead it,” said Fabio Klein, Divisional President, Danfoss Commercial Compressors.