GEA AWP Unveils HSX and TRplus Valves for Industrial Refrigeration

GEA AWP, a leader in industrial refrigeration solutions, has unveiled two significant advancements: the HSX high-pressure float valve, designed for NH₃ and CO₂ refrigeration systems, and the enhanced TRplus thermostatic 3-way valves. These innovations aim to improve energy efficiency, simplify operations, and expand the range of applications for industrial cooling and heating systems.

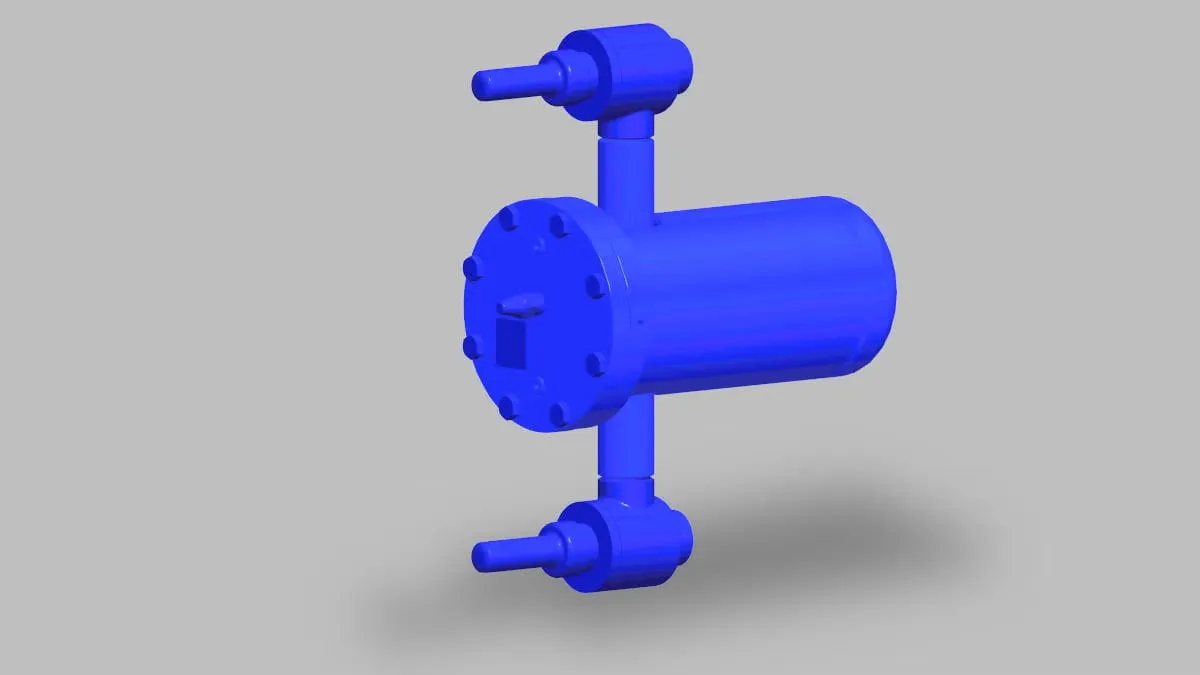

HSX High-Pressure Float Valve: Efficient, Reliable, and Energy-Saving

The HSX high-pressure float valve is a purely mechanical solution requiring no electricity, making it ideal for industrial applications such as cold storage, chemical processing, cement production, and the pharmaceutical industry. Its innovative design allows operators to harness low condensing temperatures, enabling significant energy savings - up to 13% for a 5°C reduction in condensing temperature.

Key Features and Benefits

- Energy Efficiency: Reduces flash gas formation and optimizes hot gas defrosting, achieving up to 50% energy savings compared to traditional methods.

- Robust Design: Available in steel with housing material compliant with DIN EN 12284 and AD-2000 standards.

- Wide Application Range: Supports cooling capacities up to 2,646 kW, with a temperature range of -60°C to +75°C and a nominal pressure rating of PS 40.

- Simplified Operation: Self-regulating mechanism ensures optimized condensation conditions without the need for additional high-pressure collection tanks.

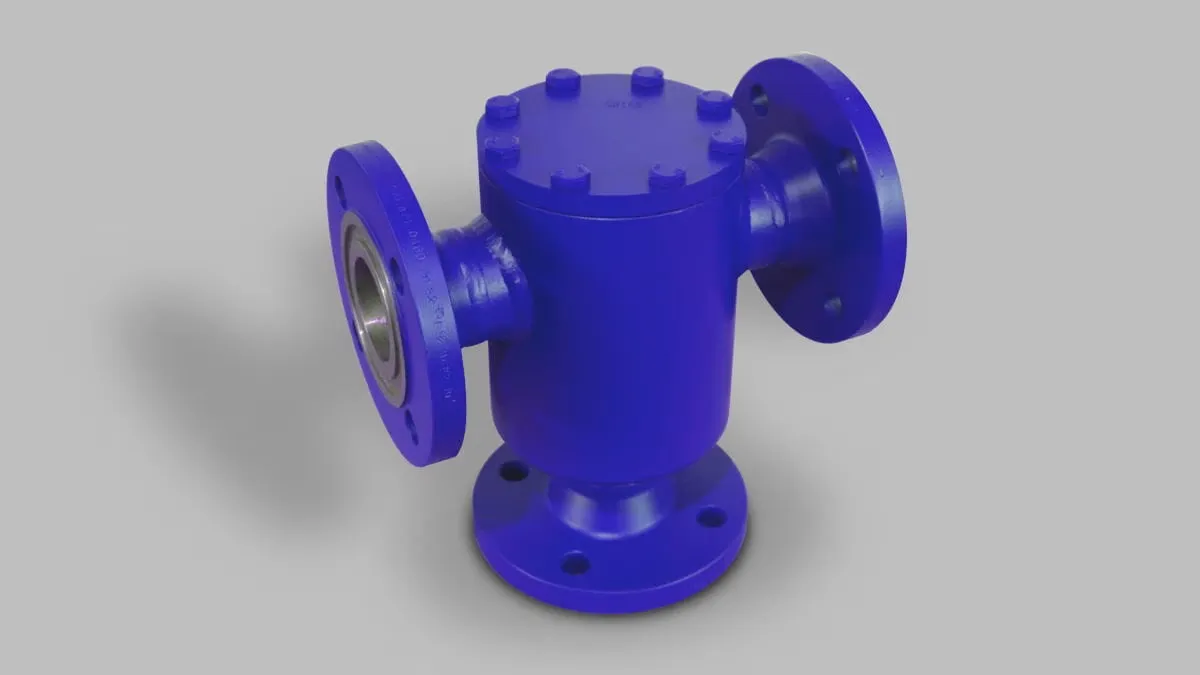

TRplus Thermostatic 3-Way Valves: Enhanced Usability and Precision

The TRplus thermostatic 3-way valves have been redesigned for easier maintenance, allowing quick replacement of control elements. These valves deliver reliable and precise liquid temperature control without requiring an external power supply.

Key Features and Benefits

- Versatility: Suitable for a wide range of processes in the refrigeration and heating industries, with a temperature range of -60°C to +200°C and a pressure rating of PS 63.

- Durable Construction: Available in steel, stainless steel, and cryogenic steel to meet diverse operational requirements.

- Ease of Maintenance: Simplified installation and operation ensure trouble-free performance in mixing or diverting fluids based on temperature requirements.

Supporting Industrial Innovation

Both the HSX high-pressure float valve and TRplus thermostatic 3-way valves exemplify GEA AWP's commitment to delivering cutting-edge solutions for industrial refrigeration and heating. These products cater to a wide array of industries, including food and beverage, pharmaceuticals, chemical processing, and even specialized applications like artificial ice rinks and indoor ski slopes.

About GEA AWP

GEA AWP is renowned for developing advanced valves and components for industrial refrigeration systems, including solutions for extreme temperatures and pressures. With products designed for applications ranging from heat pumps to chemical processes, GEA AWP continues to lead innovation in energy-efficient and sustainable cooling and heating technologies.