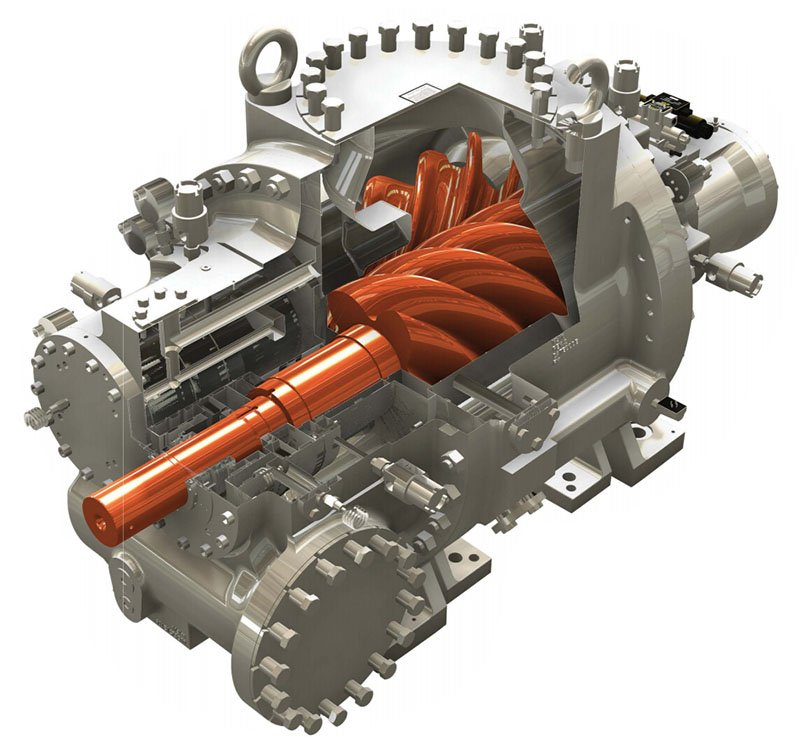

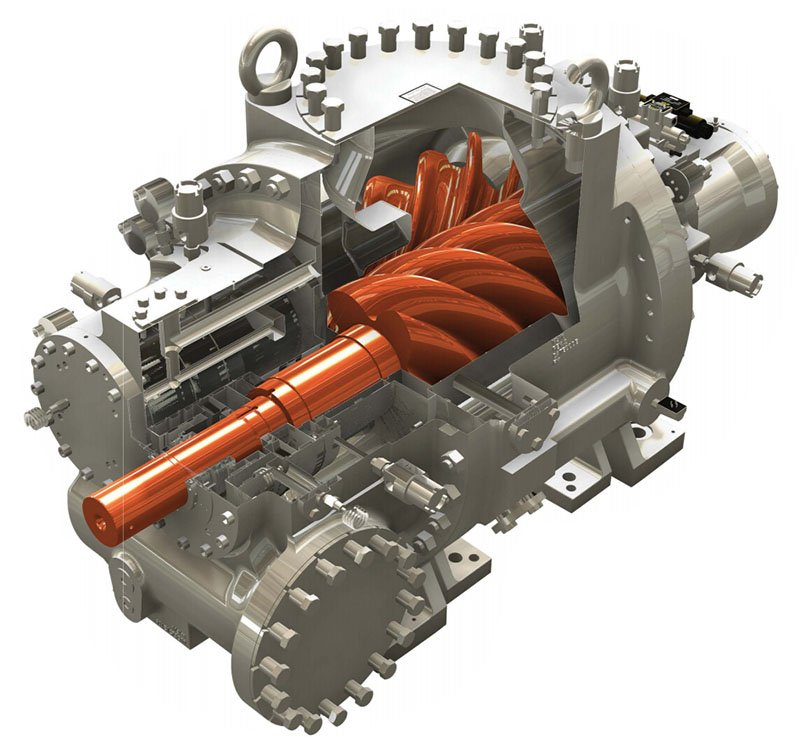

Johnson Controls has introduced its new SBTP Series 408- mm (16.1-in.) sleeve-bearing screw compressor and the HPS Series 273-mm (I 0.7 -in.) high-pressure screw compressor.

"The size of the sleeve-bearing compressor (408 mm) matches the anti-friction bearing 408-mm compressor that was an extension on the large end of our range several years ago. The high-pressure compressor is also an extension of an existing line, giving us almost four times larger capacities," said Robert F. Fahey, GM, Global York Process Systems, a unit of Johnson Controls.

The two new designs - sleeve-bearing compressors and high-pressure compressors - rely on many of the features of the earlier screw compressor designs. "For example, both designs incorporate our variable volume ratio feature to match the compressor performance to the desired compression ratio," said Fahey.

Operating parameters include housings in ductile iron and cast steel, high-efficiency rotor design, step-less capacity control, variable volume ratio, and- for the SBTP- externally accessible proximity probes and bearing resistance temperature detectors, among others. The new designs should be able to handle any application condition, according to Johnson Controls, because the SBTP screw compressor is designed for 600 psig (41 bar) and the HPS is targeting II 00 psig (76 bar). The compressors can handle commercially available refrigerants, natural gas, carbon dioxide (CO), hydrocarbons, and process applications.

"Screw compressors have proven to be a reliable and economical alternative to centrifugal compressors in this size range. Furthermore, the high-pressure design was prompted by increased fuel gas pressure requirements on today's gas turbine, as well as the growing popularity of industrial heat pumps, particularly in areas with high energy costs, such as Europe," said Fahey.

The compressors are currently undergoing lab testing and field trials. Johnson Controls recently completed construction of its new US$6.7 million screw compressor testing laboratory (see July 2017 Gas Compression Magazine, Technology Backed By The Confidence Of Testing, p. 40). The compressors will be manufactured in the Johnson Controls legacy plant in Waynesboro, Pennsylvania, USA.

Source: Johnson Controls