Mitsubishi Heavy Industries Thermal Systems, Ltd. has launched the ETI-W, a centrifugal heat pump designed to utilize waste heat and supply hot water at temperatures up to 90℃, with a maximum capacity of 640 kW. The system targets industrial and commercial applications requiring high-temperature water, traditionally provided by boilers.

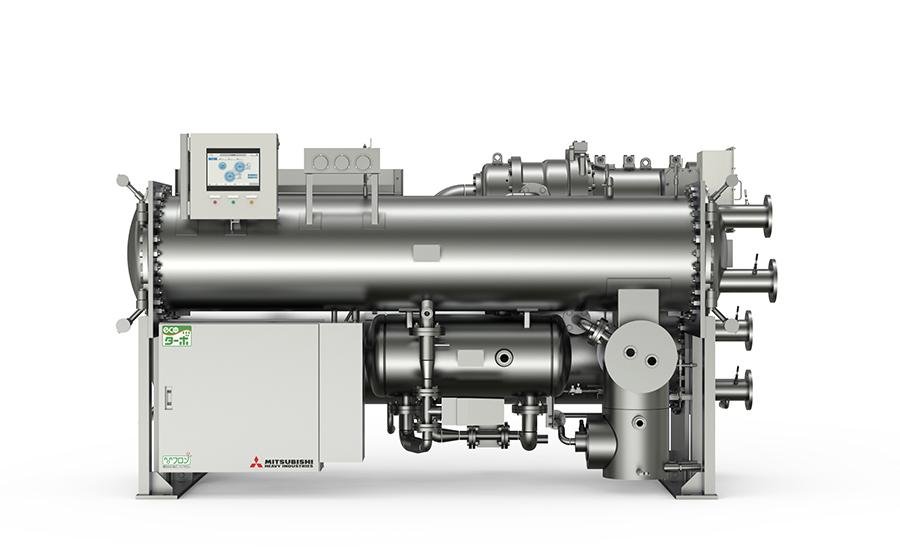

The ETI-W uses waste heat from factory production processes as a heat source and achieves a Coefficient of Performance (COP) of 4.01 when delivering hot water at 90℃. It is designed with centrifugal compressors, adapted from the company’s centrifugal chillers, and integrates a shell-and-tube heat exchanger and inverter starter panel for compact installation and enhanced performance.

The unit operates with the non-fluorocarbon refrigerant HFO-1233zd(E), which has a global warming potential (GWP) of 1 and no ozone depletion potential. This aligns the system with environmental regulations while maintaining energy efficiency.

Applications for the ETI-W include manufacturing processes in electronics, automotive, food, chemical, and pharmaceutical industries, as well as hot water supply in commercial facilities and accommodations. The product extends the company’s heat pump lineup, which includes heat recovery and commercial heat pumps.

MHI Thermal Systems stated: “With the launch of this product, our lineup of industrial and commercial heat pump utilities… will be further expanded across a wide range of hot water supply coverages and capacities, contributing to energy savings for our customers.”