A new analytical software tool is now available that helps businesses select and manage the most efficient refrigeration systems for their premises to save energy and operating costs. Resource Data Management’s newly developed software – Refrigeration Performance Indicator (RPI) – offers industry-first benefits: it provides businesses and designers with data about the efficiency, carbon footprint, and running costs of their refrigeration systems on a granular level. RPI’s real-time calculations allow businesses to make like-for-like comparisons between individual refrigeration display cases, coldrooms, evaporators, system designs, or sites.

Identifying the most efficient refrigeration system design

For the first time, businesses can now compare the efficiency of various refrigeration system designs like-for-like. They can now choose the system that delivers the smallest carbon footprint and running costs in the context of their sites.

Using RPI, businesses can analyse the impact of factors such as energy use, heat reclaim, system size, different manufacturers’ equipment, and environmental conditions on their system’s efficiency. RPI also calculates an electrical coefficient of performance (COPe) which further helps the comparison of different systems. With this data, businesses can make the most cost-effective and environmentally-friendly decision when choosing a refrigeration system.

Over time, businesses can also use RPI to assess the impact of retrofits, seasonal changes, or operational changes on the efficiency of their refrigeration system.

Comparing performance data of individual system components

As an industry-first, RPI offers performance data for individual refrigeration system components, including individual display cases, coldrooms, and evaporators. By doing so, RPI diverts from the industry standard of using only energy submetering for the whole refrigeration system to determine energy use. Using the situationally adjusted data from RPI, users can identify system components with unusually high energy use which facilitates corrective action and predictive maintenance. This, in turn, keeps maintenance and operational costs low while reducing the carbon footprint and maintaining the system's efficiency.

Analysing data

Using RPI, businesses can access data about different components of their refrigeration system broken down further into different units. RPI calculates evaporator duty which is broken down into a running, average hourly, running daily total, and previous day total kWh cooling.

Display case duty is split into total device duty and duty/m length. This facilitates comparing individual cabinets and efficiency regardless of length.

Total system electrical energy input, heat reclaim output, and COPe, are also broken down into current, hourly, running total, full previous day kW electrical, kW heating and overall COPe values.

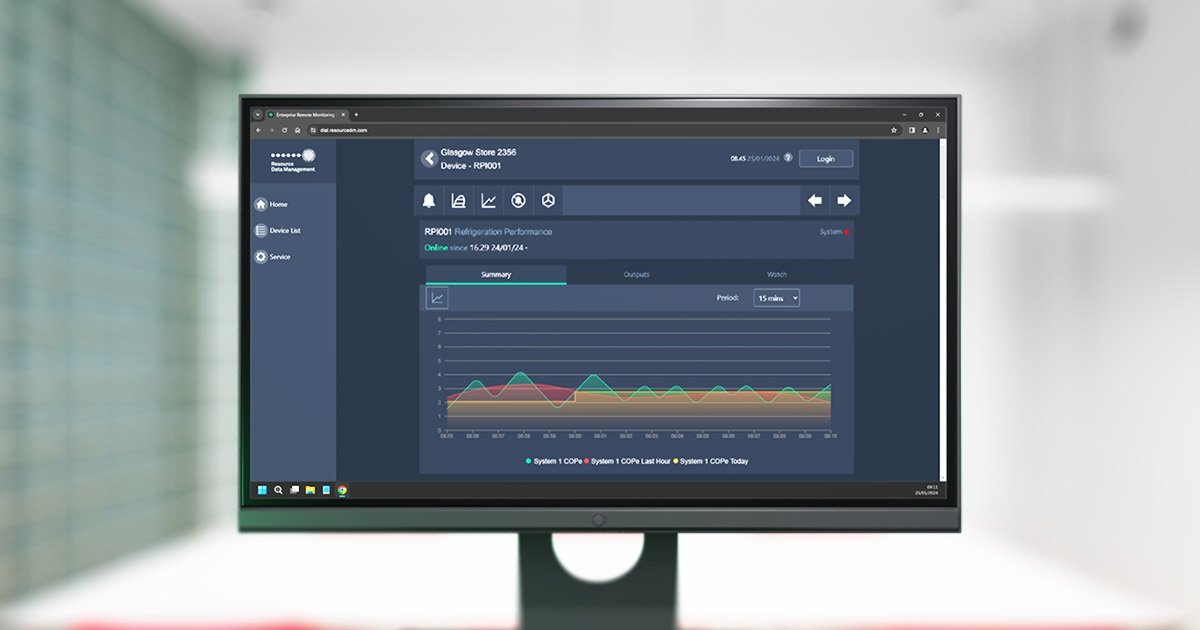

Quick data interpretation

RPI provides a snapshot of its findings in an easily understandable graphical format. This enables users to see results at a quick glance to notice trends. But users also have the option to export data to drill down further into the results and use them for their own calculations about system efficiency.