Modular foaming mould: advanced production solutions for commercial refrigeration industry.

Saip has developed several solutions for the production of refrigerated display cabinets and vending machine cabinets which improve productivity, ensure energy saving and reduce environmental impact.

Saip face-up Foaming Fixture thanks to the face-up filling technology performs better filling and foam density distribution in the cavity of the cabinet. The foaming fixture top platen is fixed while the foaming fixture bottom platen has an up and down vertical movement by means of servo-motor electrical cylinders, allowing the automatic processing of the selected cabinet model to foam. The use ofElectrical Cylinders overcomes the limits of traditional systems, hydraulics or others, achieving remarkable advantages such as reduction of energy consumptions and of environmental impact because of lack of wear, maintenance not required and lack of waste oils.

Technical characteristics:

- fixture side walls made of aluminum plate with built-in pipes for conditioning water circulation

- plugs assembling to the fixture top platen by means of automatic system

- plugs heating system through hot air circulation

- width, length, depth adjustment

Another Saip innovative solution (patent pending) is the Automatic Heating System for the plugs that allows preheating of the foaming plugs prior to the use in the process. A dedicated plant management and process control system is focused on verifying that the cabinet to process, once arrived at related plug from the pre-assembling line, is the correct one.

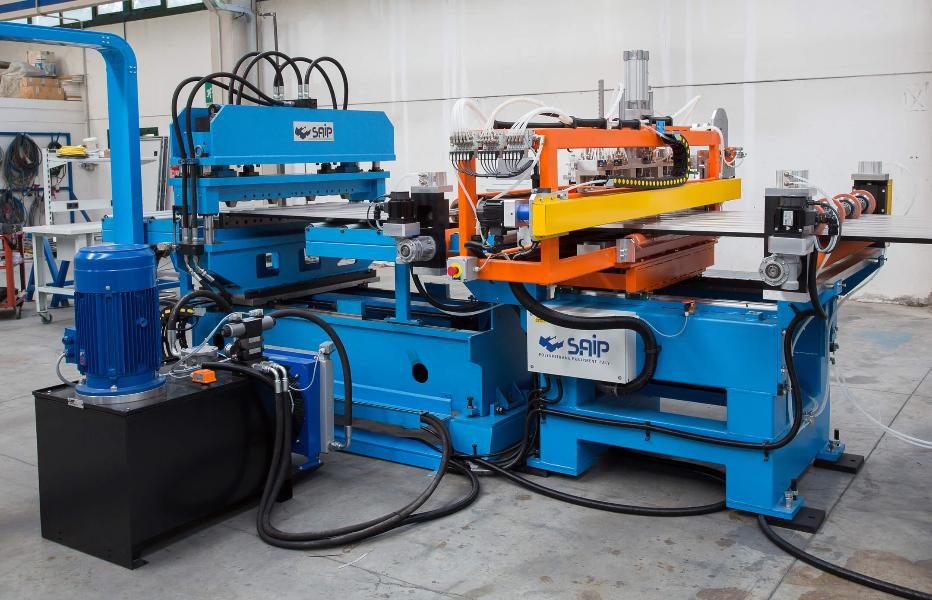

Overlapping & Endlapping system in the process of sandwich panel production

Saip Overlapping & Endlapping solution (panel longitudinal junction and foam-free area at the eaves) overcomes the limits of traditional methods which, according to situations, could imply: risk of rust, polyethylene strip management, in terms of the laying activity and the storage of different size stripes, production and management of waste of foam and of metal sheets, just to name a few.

With SAIP overlapping and endlapping solution, the panel is created before the foaming phase of the two surfaces with a cutting system by means of a shear and a consecutive moving overlapping system whose measurement can vary from a minimum of 10 mm to a maximum of 300 mm. After the overlap of the metal sheet, a polypropylene strip is applied at the end of the overlapping sheet so as to seal the area and prevent foam infiltration. The polypropylene strip in question has a unique measure that applies to all overlapping measures. The panel is cut using a disc that cuts the internal sheet of the panel and the foam to a certain thickness; the rest of the foam is removed with a water-jet system. The separation of the panels takes place by accelerating the panels at the exit.

SAIP overlapping and endlapping solution overcomes the limits of traditional methods allowing the advantages such as: better panel finishing, less waste of raw materials, reduction of power consumption and reduction of labor costs.